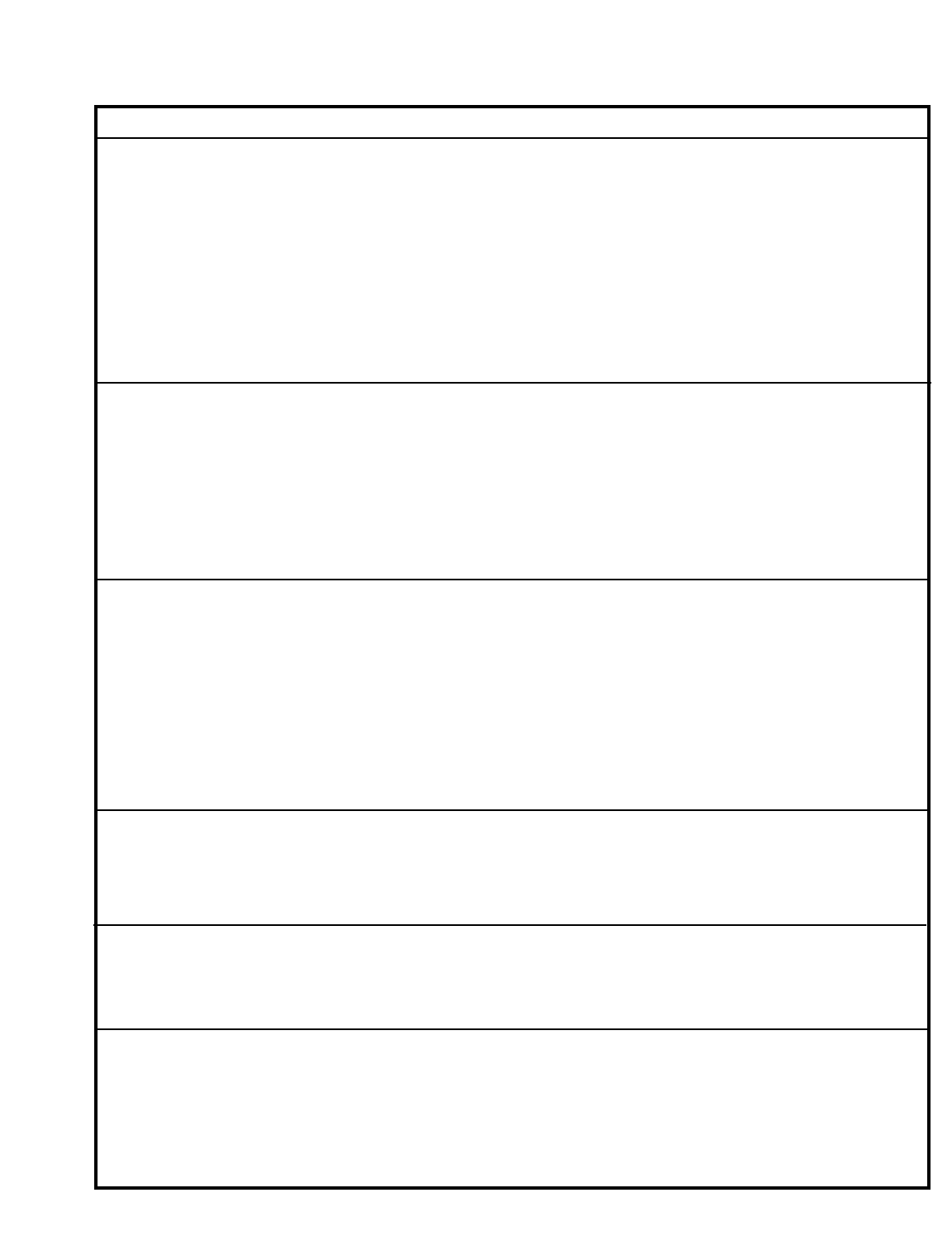

6.0 TROUBLESHOOTING CHART (Continued)

TROUBLE

Low system air pressure

High coolant

consumption/coolant in

air system

Water in air system

Excessive noise level

Excessive vibration

Pressure relief valve

opens

CAUSE &/OR DISPLAY

Compressor running in

UNLOAD Mode.

Controller off-line set point too low.

Dirty air filter element.

Air leak.

Moisture separator trap drain

stuck open.

Inlet valve not fully open.

System demand exceeds compressor

delivery.

Excessive coolant level.

Plugged separator element.

Separator element leak.

Plugged separator scavenge

screen/orifice.

Compressor operating at low pressure

(75 psig [5.2 bar] or below).

Coolant system leak.

Defective moisture

separator/drain trap

Trap drain or drain piping plugged.

Aftercooler core dirty.

Enclosure panels not in place.

No aftercooler on unit.

Drain line/drip leg incorrectly installed.

No refrigerated or desiccant dryer

in air system.

Compressor defective. (Bearing or gear

failure or rotor contact.)

Enclosure panels not in place.

Loose component mounting.

Loose components.

Motor or compressor

bearing failure.

External sources.

Compressor operating over pressure.

Defective valve.

WHAT TO DO

■ Press LOAD button.

■ Press STOP button.

Set off-line set point at a higher value.

■ Check filter condition. Replace as required.

■ Check air system piping.

■ Inspect and repair.

■ Inspect and repair.Check control system operation.

■ Install larger or an additional compressor.

■ Check level, lower if necessary by draining.

■ Check separator pressure drop.

■ Check separator pressure drop. If low, replace element.

■ Remove and inspect screen/orifice. Clean if required.

■ Operate at rated pressure. Reduce system load.

■ Inspect and repair leaks.

■ Inspect and clean if required.

Replace separator/trap if defective.

■ Inspect and clean.

■ Inspect and clean.

■ Install enclosure panels.

■ Install aftercooler.

■ Slope drain line away from trap.Install drip leg.

■ Contact local Ingersoll-Rand distributor.

■ Contact authorized distributor immediately.

Do not operate unit.

■ Install enclosure panels.

■ Inspect and tighten.

■ Inspect and tighten.

■ Contact authorized distributor immediately.

Do not operate unit.

■ Inspect area for other equipment.

■ Adjust Intellisys set points.

■ Replace valve.

47