46

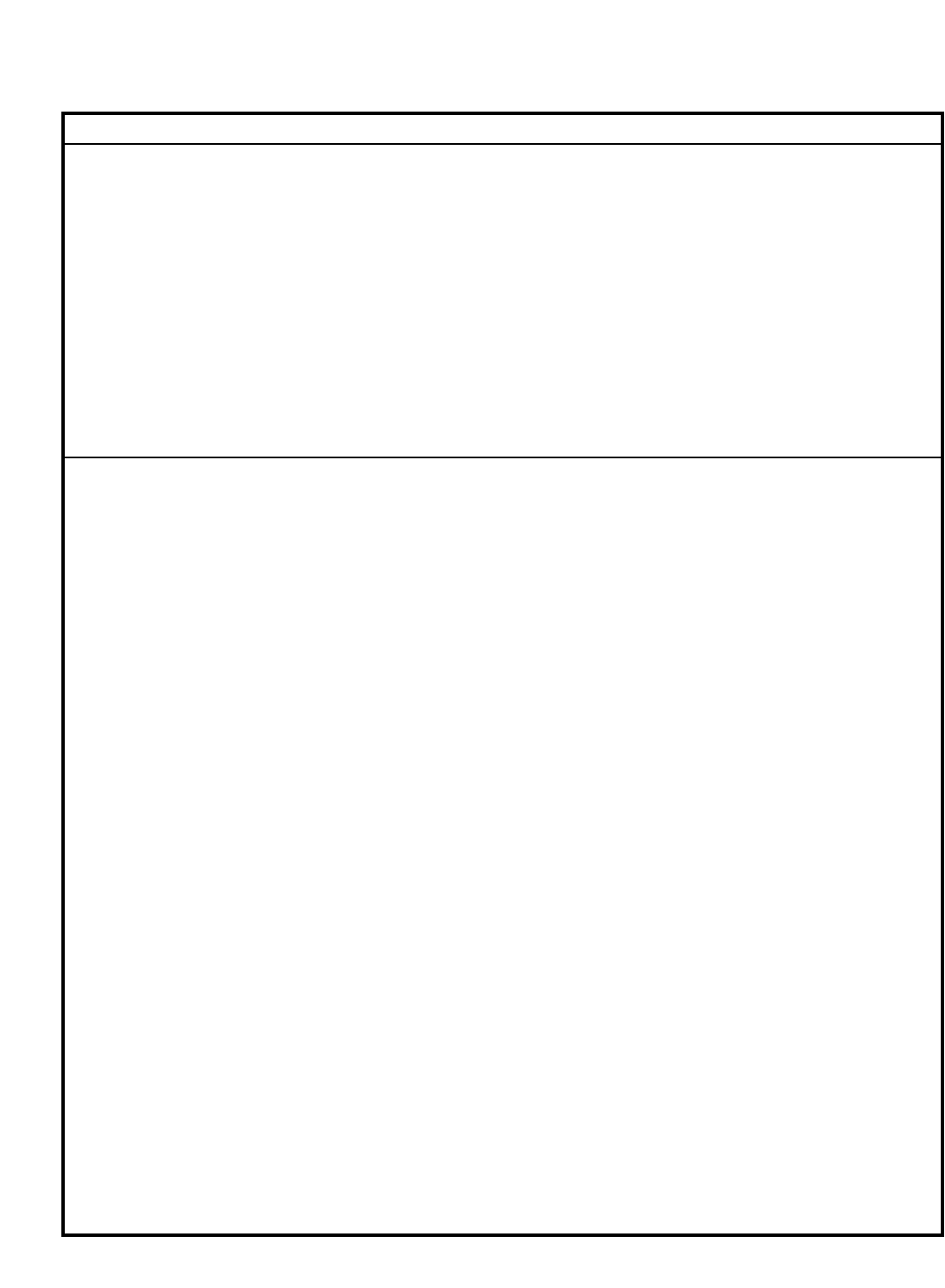

6.0 TROUBLESHOOTING CHART

TROUBLE

Compressor fails to start.

Compressor shuts down.

NOTE: If a shutdown

occurs, press the Status

button once to activate

the display table.Using

the adjacent up and

down arrows, the values

displayed will be those

immediately preceding

shutdown. Use these

values when

troubleshooting a

problem.

CAUSE &/OR DISPLAY

110/120V control voltage not available,

CONTROL POWER LOSS

STARTER FAULT

EMERGENCY STOP

MAIN (OR FAN) MOTOR OVERLOAD

SENSOR FAILURE XXXX

CHECK INLET CTRL SYS.

Intellisys 24 VAC control voltage not

available

Display panel and power on light does

not illuminate.

HIGH AIREND DISCH TEMP.

LOW UNLOAD SUMP PRESS.

CHECK INLET CTRL SYS.

SENSOR FAILURE XXXX

CHECK MOTOR ROTATION

MAIN MOTOR OVERLOAD

FAN MOTOR OVERLOAD

STARTER FAULT

CHECK SET POINTS

CONTROL POWER LOSS

STEPPER LIMIT SWITCH

REMOTE STOP FAILURE

REMOTE START FAILURE

EMERGENCY STOP

LOW SUMP AIR PRESS

CHECK INLET CONTROL

WHAT TO DO

■ Check fuses. Check transformer and wiring connections.

■ Inspect contactors.

■ Rotate emergency stop button to disengage, and press reset button

twice.

■ Manually reset main or fan motor overload relay, and press reset

button twice.

■ Check for defective sensor, bad sensor connection, or broken

sensor wires.

■ Call factory representative.

■ Check fuses.

■ Check wiring.Verify 24 VAC is within voltage tolerance (± 15%).

■ Ensure that installation area has adequate ventilation.

■ Ensure that cooling fan is operating. If not, reset circuit breaker

inside starter box.

■ Check coolant level. Add if required.

■ Cooler cores dirty. Clean coolers.

■ Check for air leak from tank or blowdown piping.

■ Check for slipping or broken stepper motor coupling.

■ Call factory representative.

■ Check for defective sensor, bad sensor connection, or broken

sensor wires.

■ Interchange any two line connections (L1, L2, L3) at the starter.

■ Check for loose wires.

■ Check supply voltage.

■ Check heater setting.

■ Check for loose wires.

■ Check supply voltage.

■ Check heater setting.

■ Check for dirty cooler cores.

■ Inspect starter connectors.

■ Check for loose wires.

■ Reset to clear.

■ Calibrate sensors.

■ Check all set points.

■ Check fuses. Check transformer and wiring connections.

■ Call factory representative.

■ Check Remote Stop Switch and wiring.

■ Check Remote Start Switch and wiring.

■ Disengage emergency stop button.

■ Press reset button twice.

■ See LOW UNLOAD SUMP PRESS

■ Check for air leaks at inlet valve.

■ Check for slipping or broken stepper motor coupling.