45481785_ed1 3

NOTICE

To prevent damage to the Cylinder, do not tap or strike Cylinder on

a hard or metallic surface when removing the Rotor Bearings (3).

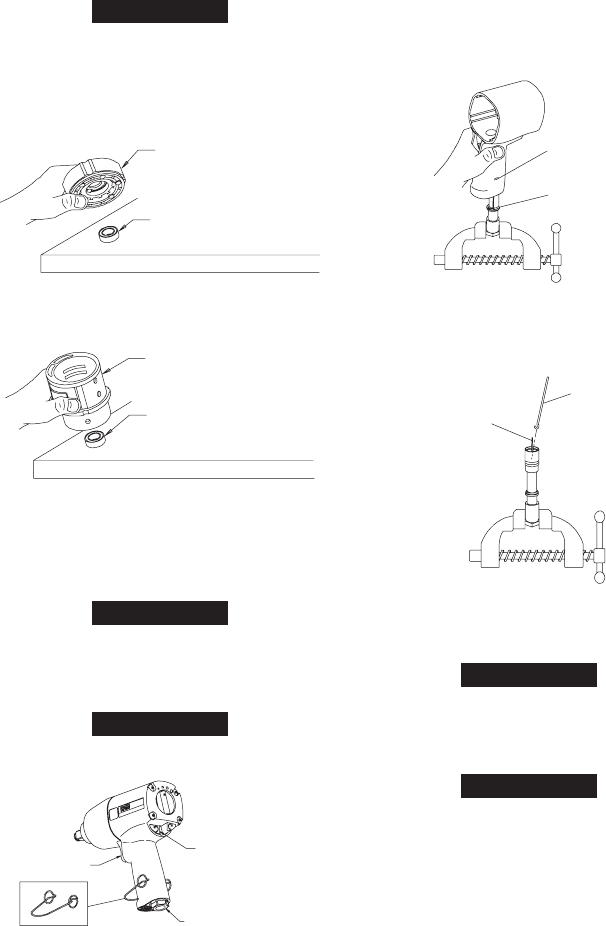

To remove the Front Rotor Bearing, hold the Front End Plate with

Front Rotor Bearing down and tap the Front End Plate on a at,

nonmetallic surface such as a work bench. This will loosen the Front

Rotor Bearing so that it will drop out of the Front End Plate. Refer to

Dwg. TPD1323.

FRONT END PLATE

FRONT ROTOR BEARING

BENCH WITH NONMETALLIC SURFACE

(Dwg. TPD1323)

4. Remove the Rear Rotor Bearing Retainer (6) from the rear of

the Rotor (5). The Rotor can now be removed from the Cylinder.

Remove the Vanes (4) from the Rotor if they need to be replaced.

CYLINDER

REAR ROTOR BEARING

BENCH WITH NONMETALLIC SURFACE

(Dwg. TPD1324)

5. To remove the Rear Rotor Bearing, hold the Cylinder with the Rear

Rotor Bearing down and tap the Cylinder on a at, nonmetallic

surface such as a work bench. This will loosen the Rear Rotor

Bearing so that it will drop out of the Cylinder. Refer to Dwg.

TPD1324.

6. Working from the rear of the Housing, push out the Motor Gasket (7).

NOTICE

When removing the Motor Gasket, do not use a screwdriver or

any other sharp object which could damage the Gasket and/or

Housing.

Disassembly of the Throttle Mechanism

NOTICE

For ease of disassembly, we recommend using the Inlet Clip

Removal Tool (36). See Dwg. TPD1681.

LEFT-HAND BUTTON

INLET BUSHING

INLET CLIP

REMOVAL TOOL

ASSEMBLY

TRIGGER

(Dwg. TPD1681)

1. Secure the Inlet Bushing in a vise. Press in both tabs of the Inlet

Retainer Clip (27) and pull upward on the Housing (19). This

will allow the Inlet Bushing to come free from the Handle of the

Housing. Refer to Dwg. TPD1326.

2. Pull the Trigger (28) from the front of the Housing and remove

the Trigger O-ring (2A).

SLOT FOR TAB

(BOTH SIDES)

TAB ON INLET

RETAINER CLIP

(BOTH SIDES)

(Dwg. TPD1326)

3. With the Inlet Bushing still in the vise, remove the Tilt Valve Seat

Retainer (1G) and Tilt Valve Seat Support (1F). Use a hooked tool

with no sharp edges to remove the Tilt Valve Seat (1E) from the

Inlet Bushing. Refer to Dwg. TPD1327.

TILT VALVE STEM

HOOKED TOOL

(Dwg. TPD1327)

4. Remove the Tilt Valve (1D) and Tilt Valve Spring (1C) if damaged.

5. Remove the Inlet Bushing Seal (1B) and Inlet Retainer Clip (27) if

damaged. Remove Washer (1A).

NOTICE

Do not remove the Inlet Bushing Screen (20A) from the Inlet

Bushing unless it is damaged. Clean the Inlet Bushing Screen by

using a suitable cleaning solution in a well ventilated area.

Disassembly of the Reverse Valve Mechanism

NOTICE

The Reverse Valve Assembly cannot be removed without rst

removing the Forward and Reverse Buttons (4A) and (4B).

Therefore, it is important that the procedure below be followed

exactly.

1. Notice the notches on either side of the partition. These notches

indicate the correct location for insertion of a thin-bladed

screwdriver used for removing the Forward and Reverse Buttons.

Insert the screwdriver between the partition and the Button

which is fully extended. Gently pry against the Button to

disengage the detent so that the Button can be removed. After

the Button is removed, reach inside the Housing and rotate the

Reverse Valve to extend the remaining Button. Repeat the above

procedure for the remaining Button. Refer to Dwg. TPD1328.