6 45481785_ed1

NOTICE

When re-installing the Inlet Bushing Assembly (20), pull the

Trigger (28) outward and make sure that the Reverse Button (4B)

is depressed before snapping the Inlet Bushing Assembly back

into the Housing.

3. Install the Inlet Bushing Assembly by pushing it into the hole in

the Housing until you see and hear the tabs on Inlet Retainer Clip

snap into place through the slots in Housing handle.

NOTICE

The Reverse Button (left) (4B) must be pushed in before the

Trigger can be installed. Otherwise, the Trigger will be damaged

during installation.

4. Install the Trigger by pushing it into the handle until a click is

heard indicating that it is properly engaged.

INSTALLATION

OF MOTOR

GASKET

(Dwg. TPD1336)

Assembly of the Motor

NOTICE

When disassembling, assembling or pulling the Motor, we

recommend replacement of the Motor Gasket (7).

1. Install the Motor Gasket in the Housing making sure that the

grooves in the tab of the Motor Gasket t around ridge in the

Housing. Refer to Dwg. TPD1336.

2. Install the Rear Rotor Bearing (3) into the rear of the Cylinder (1).

3. Install the Rotor in the Cylinder and secure with the Rear Rotor

Bearing Retainer (6).

4. Install Vanes (4) in the slots in the Rotor (5).

5. Install the Front Rotor Bearing (3) into the Front End Plate (2).

Install the Front End Plate on the Cylinder by pressing on the

inner race of the front Rotor Bearing until the Bearing is seated on

the Rotor Shaft.

6. Install the Power Management Dial Seal (5A) on the Power

Management Dial (35) and install the Dial in the end of the

Cylinder.

7. Clean the Silencer (6A) using a suitable cleaning solution in a

well-ventilated area. Position the Silencer over the top of the

Cylinder and insert the Motor Assembly into the Housing (19),

Power Management Dial end rst.

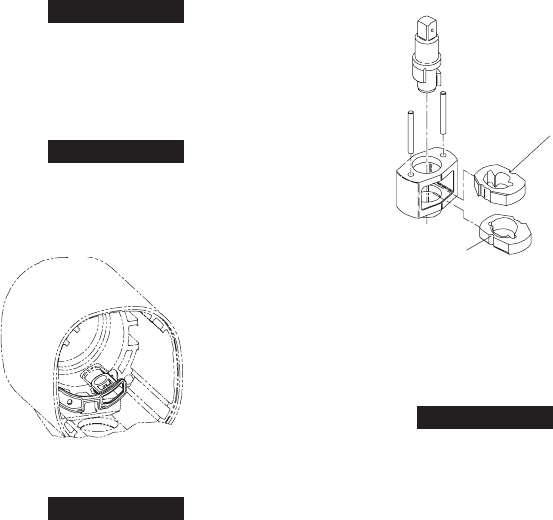

Assembly of the Impact Mechanism

TOP HAMMER

HALF--ROUND

NOTCH O N RIGHT

BOTTOM HAMMER

HALF--ROUND

NOTCH O N LEFT

(Dwg. TPD1535)

1. Coat the Hammers (14) with a light lm of No. Ingersoll Rand

105-1LB Grease or Ingersoll Rand No. 105-8LB Grease.

2. Heavily coat the jaws of the Anvil (8) with Ingersoll Rand No.

105-1LB Grease or Ingersoll Rand No. 105-8LB Grease.

3. Replace the Hammers in the Hammer Frame (12) exactly as they

were when you marked them prior to disassembly.

NOTICE

If you are installing new Hammers or want to change the location

of the existing Hammers to utilize both impacting surfaces, slide

the Hammers in the Hammer Frame so that the half-round notch

on one Hammer is located on one side of the Frame and the

half-round notch on the other Hammer is located on the other

side of the Frame.

4. Replace the Hammer Pins (13).

5. Examine the base of the Anvil (8) and note its contour. While

looking down through the Hammer Frame, swing the top

Hammer to its full extreme one way or another until you can

match the contour of the Anvil. Enter the Anvil into the Hammer

Frame and through the rst Hammer. Swing the bottom Hammer

in the opposite direction from the top Hammer and maneuver

the Anvil slightly until it drops into the bottom Hammer. Refer to

Dwg. TPD1535.

Assembly of the Air Wrench

1. Position the Motor Housing (19) in leather-covered vise jaws with

the splined shaft of the Rotor in a horizontal position.

2. Place the assembled impact mechanism down onto the splined

hub of the Rotor.

3. Position the Hammer Case Gasket (18) against the face of the

Motor Housing.