32

7/120 (P425AWIR), 9/110 (XP375AWIR), 10/105 (HP375AWIR), 14/85 (VHP300AWIR),

7/170 (P600WIR), 10/125 (HP450WIR), 14/115 (VHP400WIR)

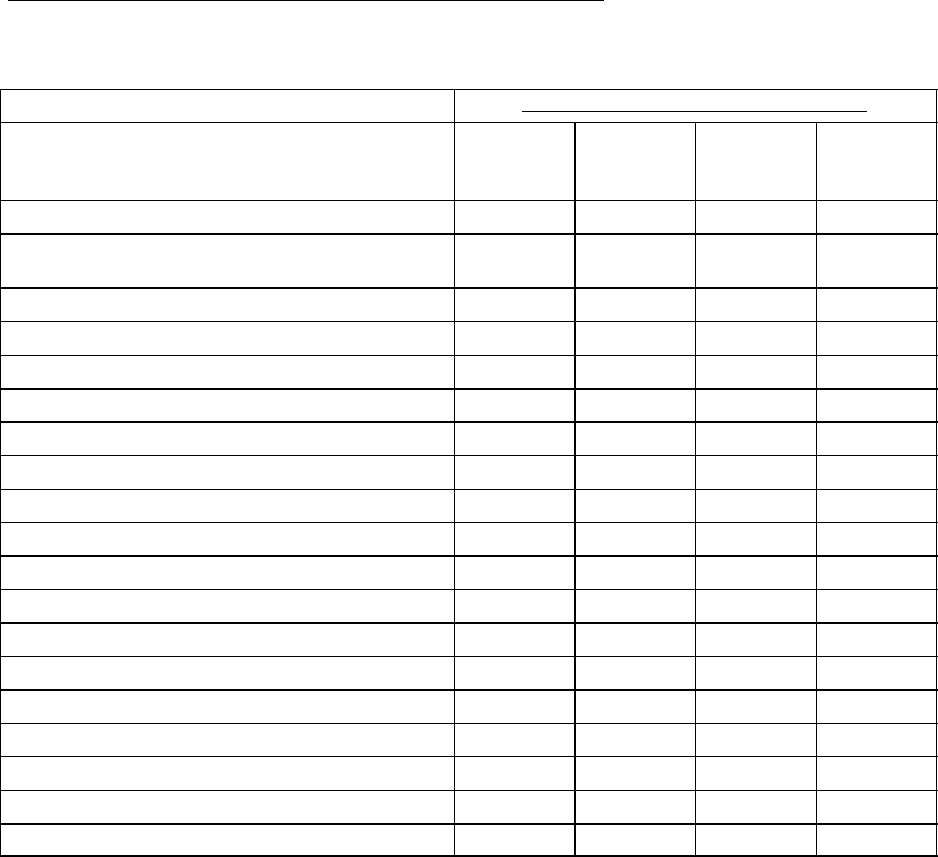

Lubrication and Maintenance Service Interval Chart

NOTE: The Service intervals below are for standard industrial engines. See details in Sections which

follow these charts.

Item Lubrication and Maintenance Service Intervals

Check Engine Oil and Coolant Level Daily 500 Hours/12

Months

2000

Hours/24

Months

As Required

Check Fuel Filter/Water Bowl S

Check Air Cleaner Dust Unloader Valve & Restriction Indicator

Gauge a

S

Visual Walk Around Inspection S S

Service Battery S

Check Manual Belt Tensioner and belt wear S

Change Engine Oil And Replace Oil Filter S

Clean Crankcase Vent Tube S

Check Air Intake Hoses, Connections, & System S

Replace Fuel Filter Elements—Bleed Fuel System S

Check Belt Tensioner and Belt Wear S

Check Engine Electrical Ground Connection S

Check Cooling System S

Pressure Test Cooling System S

Flush Cooling System S

Test Thermostats S

Check and Adjust Engine Valve Clearance S

Add Coolant S

Replace Air Cleaner Elements S

Replace Poly–Vee Belt S

A Replace primary air cleaner element when restriction indicator shows a vacuum of 625 mm (25 in.) H2O.

B During engine break–in, change the oil and filter for the first time before 100 hours of operation.

C If the recommended engine oils, or Pro–Te ct is not used, the oil and filter change interval is reduced to every 250 hours. If

diesel fuel with a sulfur content greater than 0.05% is used, the oil and filter change interval is also reduced.