04581922_ed4 EN-8

EN

Changing the Date or Time Format

The format of how Date and Time are to be displayed can be

selected.

From the Date and Time Menu, Select Date Format or Time.

Format and use the keys to select the required format and

press ENTER.

Changing the Language

The wrench can display one of several dierent languages.

This can be found in the Main Menu / Main Setup Menu / Regional

Settings / Language.

Use the keys to select between: English, Deutsche, Francais,

Espanol, Italiano, Swedish or Czech and press ENTER to select.

Changing the Decimal Point style

There is also an option to change the decimal point in displayed

numbers from a ‘.’ (period) to a ‘,’ (comma), to suit local conventions.

This is found in the Main Menu / Setup Menu / Regional Settings /

Decimal Point.

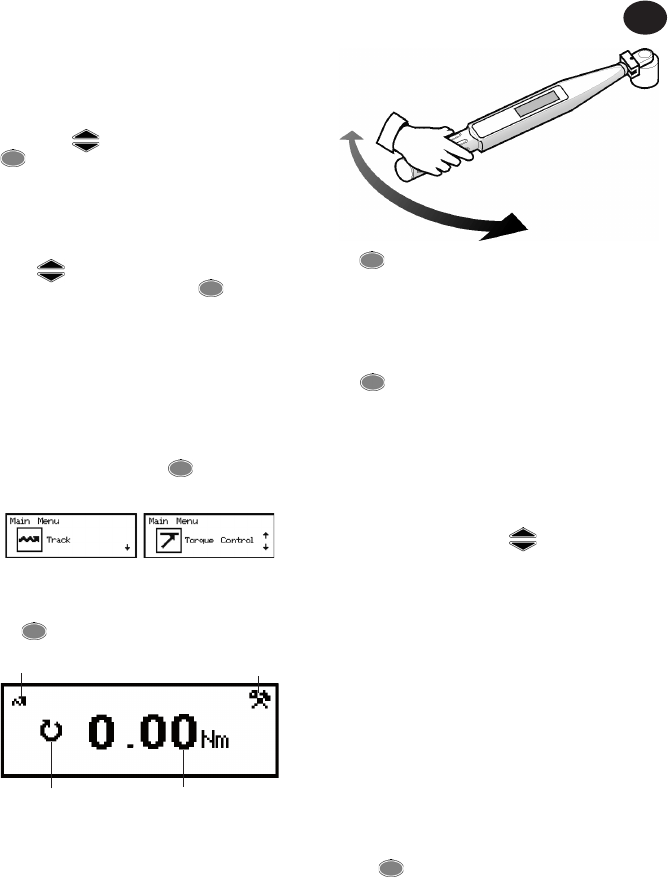

GETTING STARTED - TAKING A READING

After switching on, you will be in the Main Menu. The screen shows

just one item from the menu. Use the Up and Down arrow keys

to navigate between screens and press ENTER to access the

required mode. Shown below are the menu screens for the Track

measure mode and the Torque Control mode.

Track Mode

The simplest way to take a measurement is to use the Expert

Torque Wrench’s Track mode. Select Track from the Main menu

and Press ENTER. Track mode shows a continuous real-time

torque readout.

Tracking Screen

Direction of Rotation

Measurement Type (Track)

Setup Menu

Torque Readout

With a suitable drive adapter and socket in place, connect to the

required fastener and apply torque. Check the readout on the

display. When the torque is removed the display will revert back

to zero.

Press ENTER to access the Track Setup Menu. Here you can

change the units displayed next to the torque readout.

Torque Control

Torque Control mode monitors the peak torque applied to a

fastener and signals the operator to stop tightening once the

fastener is within a specied range. To access Torque Control mode,

scroll to Torque Control in the Main Menu and

press ENTER. The screen will immediately display the word

“WAIT” and both LEDs will turn red. During this time the wrench is

zeroing the angle sensor. Hold the wrench still until a single LED is

lit yellow to proceed.

The default display shows torque units in large bold numbers in

the center of the screen, with angle data (as indicated by the angle

symbol on the left) above in a smaller font. The current torque units

are displayed alongside the torque data. The bottom left corner of

the screen says “TORQUE” to indicate the current tightening mode.

The bottom right hand corner shows the current cycle number/

total number of samples. Using the keys, two other displays

can be accessed. One shows the angle data in larger font with the

torque data smaller in the middle. The other shows both torque

and angle in small font, with current subgroup/total subgroups on

the bottom.

Tighten the fastener at a moderate speed using a steady pull

on the wrench handle. As the wrench is pulled, the LEDs will

change color to represent various conditions. Both LEDs will turn

solid green when the lower torque limit is passed. Both LEDs will

turn solid red when the upper angle limit is passed. When the

measurement is nished the wrench will beep and both LEDs will

start ashing.

The ashing LEDs give a quick analysis of the completed

tightening. The top LED represents the relative torque value. It will

ash yellow if the torque is below the specied range, green if it is

within, and red if it is above. In a similar fashion the lower LED will

ash to indicate whether the resultant angle was below, within,

or above the specied range. There are also arrows that appear to

the right of the torque and angle values. An upward arrow means

that the given value is above the specied range, and a downward

value means that it is below the range.

Press the ENTER key to zero the angle sensor for the next

reading.

Note: The previous results will remain on the display until the next

reading is taken.