10

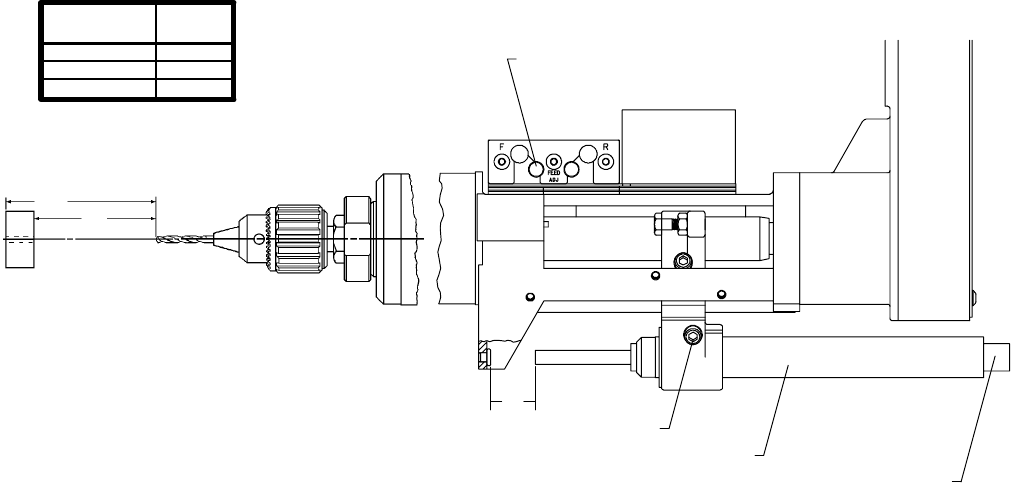

HYDRAULIC CHECK SET–UP

HYDRAULIC CHECK

‘‘X”

HYDRAULIC

CHECK

38922

38922–1

38922–2

STROKE

LENGTH

1”

2”

3”

CAP SCREW (28)

FEED RATE ADJUSTMENT

‘‘F” FEED CONTROL VALVE (103)

‘‘W”

‘‘Y”

SET–UP PROCEDURE

• Assemble hydraulic check to yoke assembly (27).

• Measure the distance from the drill point to the work piece –

distance ‘‘Y”.

• Distance ‘‘X” between the hydraulic check plunger and stop

pin (38) must be less than distance ‘‘Y” to prevent damage to

the drill point when it approaches the work piece.

• Loosen cap screw (28) and position the hydraulic check to ob-

tain the correct setting for distance ‘‘X”.

• Tighten cap screw (28) securely before operating unit.

• Increase the air flow thru the feed control valve (103) marked

‘‘F” by opening two full turns from the closed position. This will

allow the drill to advance rapidly until the plunger of the hy-

draulic check contacts the stop pin (38).

• The hydraulic check feed rate adjustment is located at the

nameplate end. Rotate the extended end until the slot at the

end of the spindle is aligned with the number 15 on the name

plate.

• Start the drill unit and the drill will advance at a rapid rate until

the plunger of the hydraulic check contacts the stop pin (38).

• Slowly rotate the extended spindle of the hydraulic check

counter–clockwise toward the number zero on the nameplate

until the drill advances at the desired rate of feed.

TO CONTROL BREAKTHROUGH

• Position the hydraulic check so the distance between the

plunger and the stop pin (38)(distance ‘‘X”) is less than the dis-

tance from the drill point to the opposite side of the work piece

(distance ‘‘W”).

• Set–up of the self–feed drill unit will be the same as explained

in ‘‘Set–Up Procedure”, page 3.