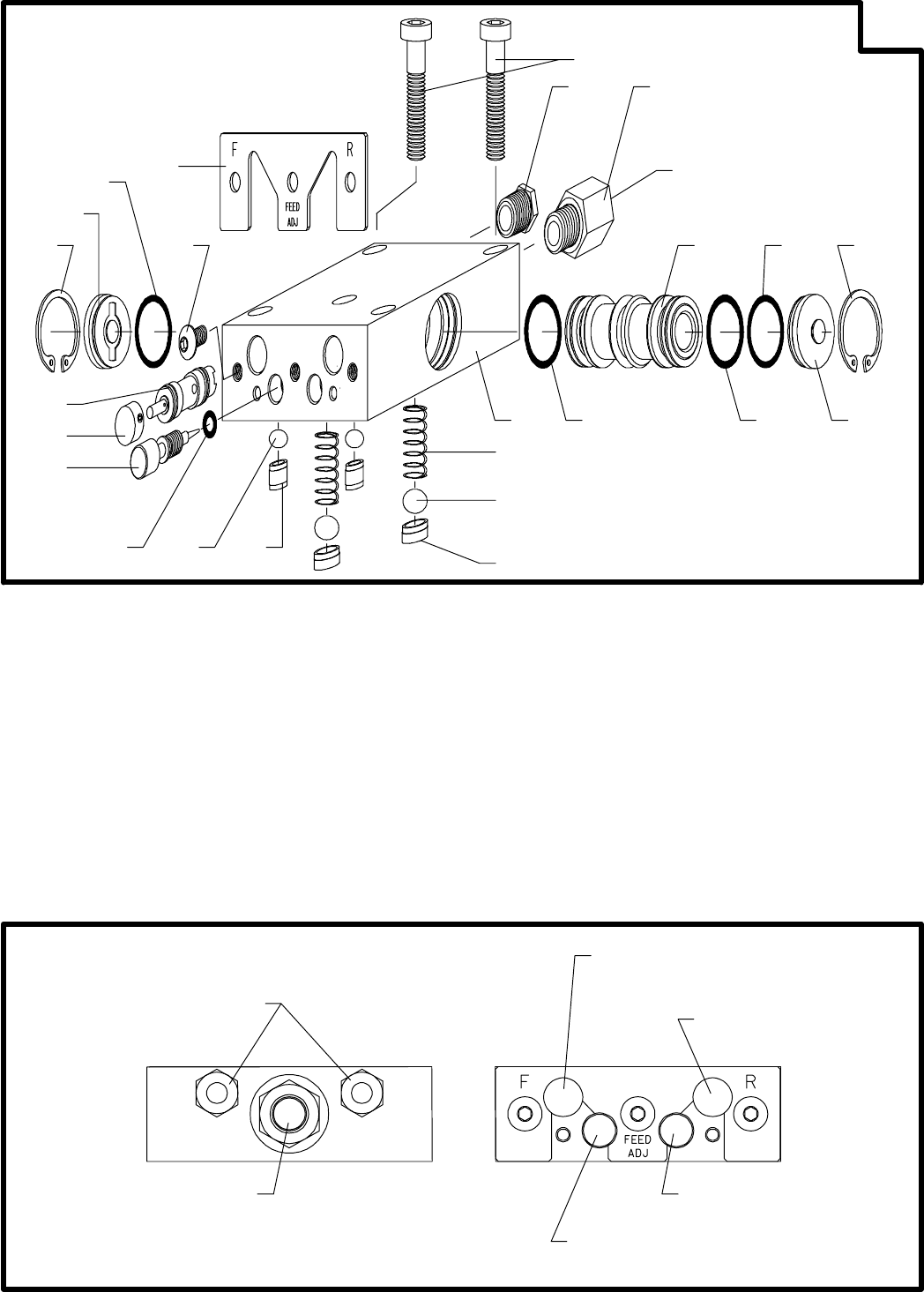

M107

26

9

76*

104 105

94

95

96

f

97 f

98

97 f

106

107

108

109

94

95

f 96

112

99

100

101

103

f 102

110

111

49674 CONTROL ASSEMBLY

* NOT INCLUDED IN ASSEMBLY

1/8–27 NPT

f INCLUDED IN 49596 SERVICE KIT.

CONTROL DISASSEMBLY

_ Control valves (100) and needle valves (103) can be serviced

without removing the control assembly from the tool.

_ Remove three screws (112), releasing face plate (99).

_ Pull control valves (100) from valve body (106).

_ Unthread and remove needle valves (103).

_ To further disassemble, remove five cap screws (76), releas-

ing control assembly from the tool.

_ Remove retaining rings (94) and end caps (95) and push

spool (98) out of valve body (106).

CONTROL ASSEMBLY

_ Lubricate all ‘‘O” rings with ARO 36460 lube when assem-

bling.

_ Assemble ‘‘O” rings (96) to grooves in end caps (95).

_ Assemble one end cap (95) to valve body (106), securing with

retaining ring (94).

_ Assemble ‘‘O” rings (97) to grooves in spool (98) and as-

semble spool into valve body (106).

_ Assemble end cap (95) to valve body, securing with retaining

ring (94).

_ Assemble ‘‘O” rings (102) to grooves in needle valves (103)

and thread needle valves into valve body (106).

_ Grease ‘‘O” rings on control valves (100) and assemble into

valve body (106).

_ Assemble face plate (99) to valve body, securing with three

screws (112).

_ Assemble control assembly to tool, securing with five cap

screws (76).

FORWARD / START

PUSHBUTTON

RETRACT / EMERGENCY

RETRACT PUSHBUTTON

RETRACT FEED RATE

ADJUSTMENT KNOB Q

FORWARD FEED RATE

ADJUSTMENT KNOB Q

EXHAUST, FEED CYLINDER

MAIN AIR INLET (1/8–27 N.P.T.)

Q TURN ‘‘IN” TO DECREASE FEED RATE.

TURN ‘‘OUT” TO INCREASE FEED RATE.