2

XX X –A

ELECTRIC SELF–FEED TOOL

HORSEPOWER

07 = .75

CONTROL CODE

A – VALVE IN HEAD

MOTOR CODE (item 11)

B = 49685–5 (3600 r.p.m.)

C = 49685–6 (1800 r.p.m.)

D = 49685–7 (3600 r.p.m.)

E = 49685–8 (1800 r.p.m.)

FE 07 4 B–

STROKE LENGTH

4 = 4” maximum

FREE SPEED

(see table below)

TOOL GENERATION

MODEL IDENTIFICATION

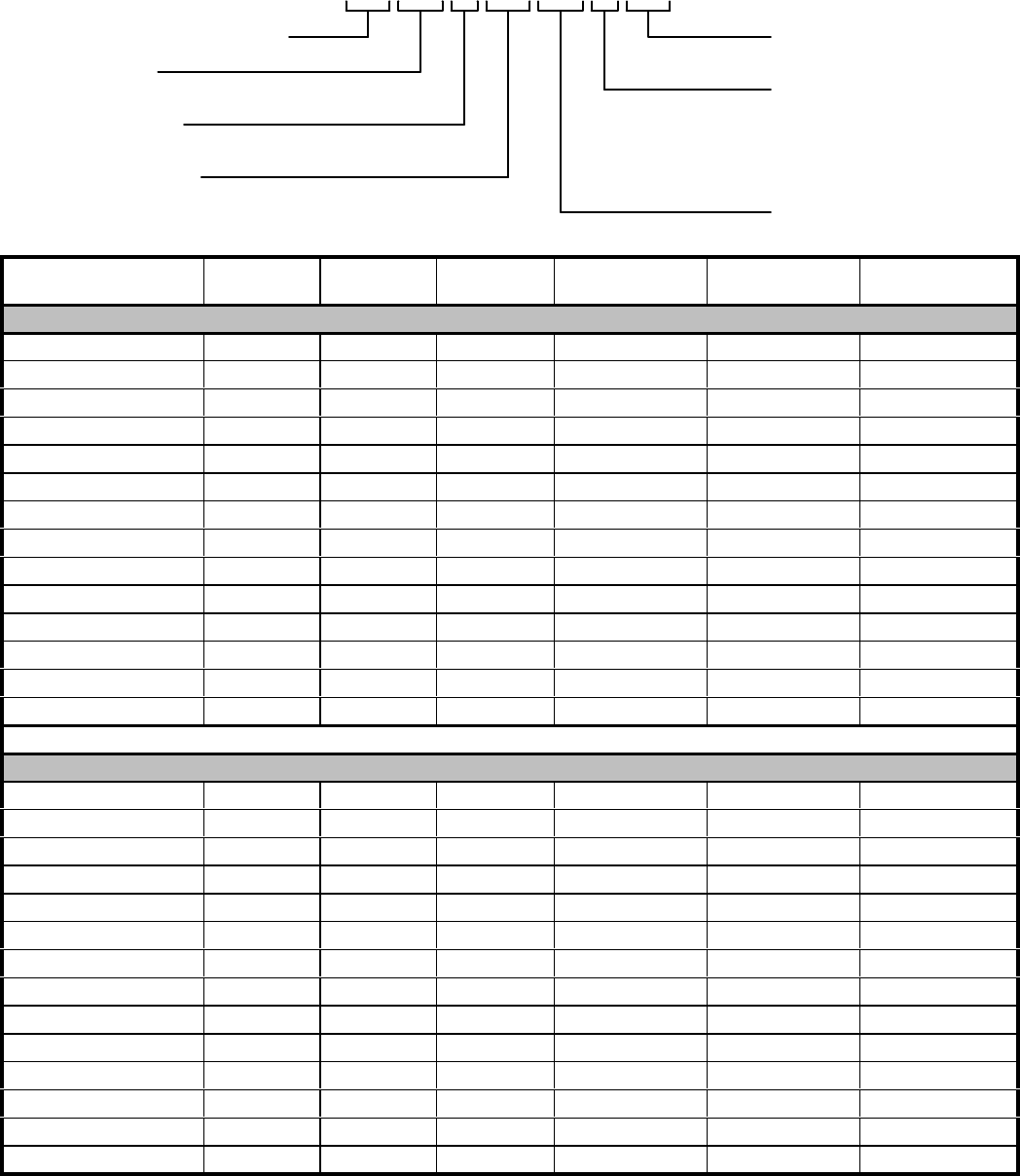

MODEL

NUMBER

R.P.M.

@ 60 Hz

R.P.M.

@ 50 Hz

PULLEY

SET

# OF TEETH

(ITEM 7)

# OF TEETH

(ITEM 12)

TOTAL

REDUCTION

3600 R.P.M. MODELS (–B and –D motor code)

FE074B–17( )–A( ) 1684 1404 49763–1 22 47 .468:1

FE074B–19( )–A( ) 1918 1600 49763–2 24 45 .533:1

FE074B–22( )–A( ) 2178 1815 49763–3 26 43 .605:1

FE074B–24( )–A( ) 2398 2000 49763–4 28 42 .666:1

FE074B–27( )–A( ) 2700 2250 49763–5 30 40 .750:1

FE074B–30( )–A( ) 3031 2525 49763–6 32 38 .842:1

FE074B–34( )–A( ) 3398 2832 49763–7 34 36 .944:1

FE074B–38( )–A( ) 3808 3173 49763–7 36 34 1.058:1

FE074B–43( )–A( ) 4274 3562 49763–6 38 32 1.187:1

FE074B–48( )–A( ) 4800 4000 49763–5 40 30 1.333:1

FE074B–54( )–A( ) 5400 4500 49763–4 42 28 1.500:1

FE074B–59( )–A( ) 5954 4961 49763–3 43 26 1.654:1

FE074B–67( )–A( ) 6750 5625 49763–2 45 24 1.875:1

FE074B–77( )–A( ) 7690 6408 49763–1 47 22 2.136:1

1800 R.P.M. MODELS (–C and –E motor code)

FE074B–08( )–A( ) 842 702 49763–1 22 47 .468:1

FE074B–10( )–A( ) 959 799 49763–2 24 45 .533:1

FE074B–11( )–A( ) 1089 907 49763–3 26 43 .605:1

FE074B–12( )–A( ) 1199 999 49763–4 28 42 .666:1

FE074B–14( )–A( ) 1350 1125 49763–5 30 40 .750:1

FE074B–15( )–A( ) 1516 1263 49763–6 32 38 .842:1

FE074B–17( )–A( ) 1699 1416 49763–7 34 36 .944:1

FE074B–19( )–A( ) 1904 1587 49763–7 36 34 1.058:1

FE074B–22( )–A( ) 2137 1781 49763–6 38 32 1.187:1

FE074B–24( )–A( ) 2400 2000 49763–5 40 30 1.333:1

FE074B–27( )–A( ) 2700 2250 49763–4 42 28 1.500:1

FE074B–30( )–A( ) 2977 2481 49763–3 43 26 1.654:1

FE074B–34( )–A( ) 3375 2812 49763–2 45 24 1.875:1

FE074B–38( )–A( ) 3845 3204 49763–1 47 22 2.136:1

MODELS WITH –EU SUFFIX ARE ‘‘EC” COMPLIANT MODELS.

INSTALLATION

The ARO model FE074B–( ) is NOT supplied with the required

motor starter. The motor starter must conform to the local / nation-

al regulations governing the use of this type of electrical equip-

ment and must provide motor overload protection. The

recommended overload setting is given on the wiring diagram.

The power supply, motor starter and the motor nameplate ratings

must be equivalent.

MOTOR: The electric motor develops a minimum of .75 horse-

power. The voltage requirements are shown in the following Elec-

trical Connection Diagram.