3

LUBRICATION

Rock Drill Oil

Always use an air line lubricator with these tools. We

recommend the following Lubricator-Unit and Lubricant:

In Line Lubricator: 6LUB12

Lubricant: Rock Drill Oil: 51378693

Attach the lubricator as close to the tool as practical.

After each two or three hours of operation and at the begin-

ning of each work shift, if an air line lubricator is not used,

disconnect the air hose and pour about 3 cc of oil into the air

inlet of the tool.

Before storing the tool or if the tool is to be idle for a period

exceeding twenty-four hours, pour about 3 cc of oil into the

air inlet and operate the tool for 5 seconds to coat the internal

parts with oil.

INSTALLATION

Air Supply and Connections:

Always use clean, dry lubricated air. Dust, corrosive fumes

and/or excessive moisture can ruin the motor of an air tool.

An air line filter can greatly increase the life of an air tool.

The filter removes dust and moisture.

Make sure all hoses and fittings are the correct size and are

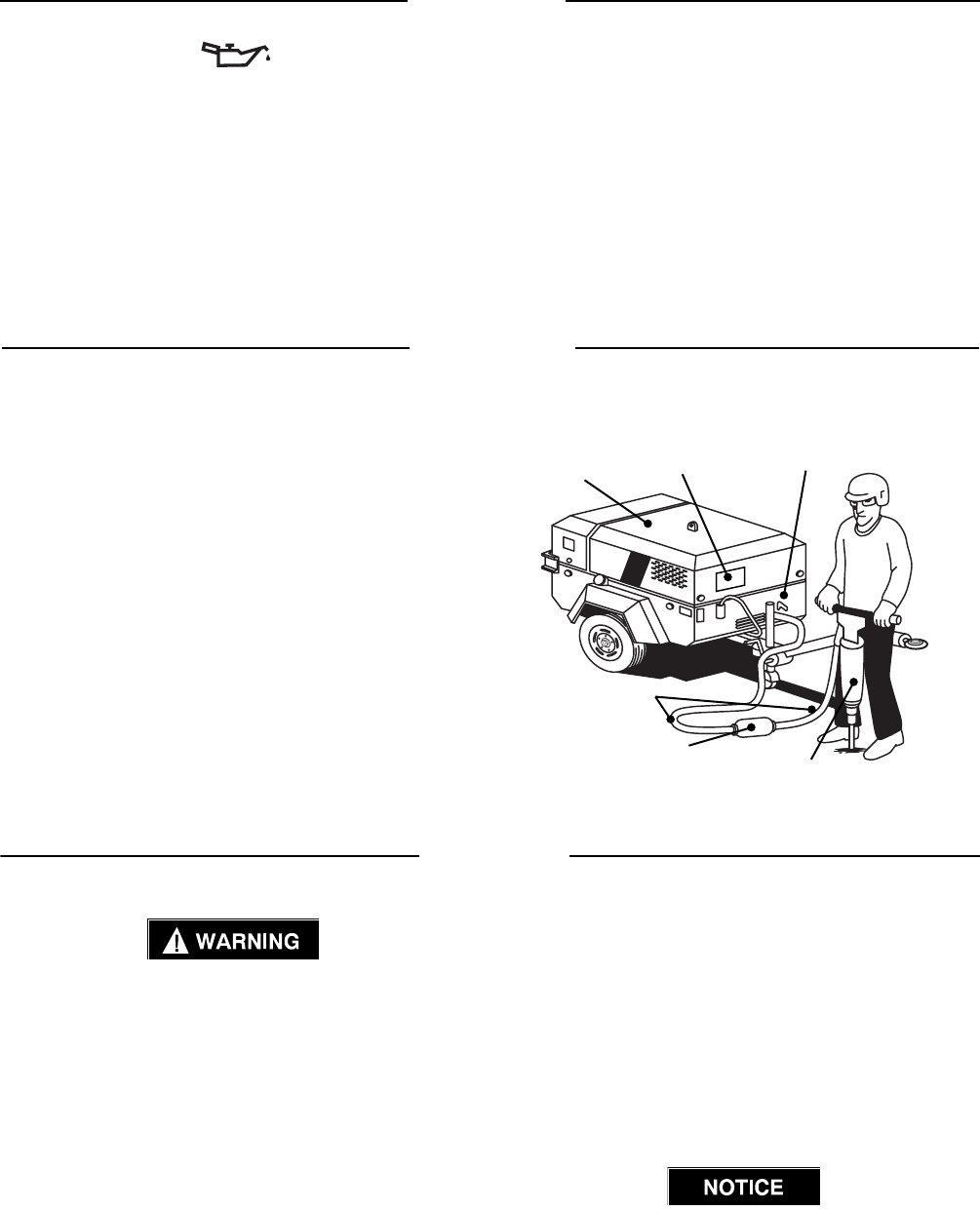

tightly secured. See diagram TP2125-1 for a typical piping

arrangement.

The tool is shipped from the factory with a custom thick

walled 3/4” NPT male inlet thread.

(Dwg. TP2125-1)

OPERATION

Accessory Installation:

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool or before performing any

maintenance on this tool. Failure to do so could result

in injury.

For Latch Type Retainer

1. Operate the Latch until it is approximately 90 degrees to

the body of the tool and clicks into position.

2. Insert the accessory into the tool until the collar of the

accessory is past the Latch.

3. Operate the Latch until it is parallel to the tool and it

clicks into position.

30-40 lbs (15-20 kg) is the recommended amount of down-

force to apply to the tool when working.

The amount of downforce is correct when the tool hits rhyth-

mically, is comfortable to hold and works efficiently.

Do not operate the tool unless the chisel is against the work

since this will cause premature wear of parts and reduce the

vibration isolation properties of the tool.

Always break material to the point of “give.” Cracking does

not result in a complete break. Clear away rubble as it is

broken since uncleared rubble blocks the point of “give.”

Always take the right size “bite” with the tool. When work-

ing new material, experiment to find the right size “bite”

required for breaking that material efficiently.

If “bites” are too big, the operator will try to pry with

the tool. This could break the chisel. The tool is designed

for demolition, not prying. Always use a pick for prying.

If “bites” are too small, the operator will be working too

slowly.

If the chisel or accessory should become stuck, do not use

excessive force or mechanical means on the tool to pull out

the chisel. Doing so will damage the vibration isolation unit.

Break out the stuck chisel with a spare chisel or tool.

COMPRESSOR

MOTOR/COMPRESSOR

SHUT OFF

MAIN LINE & AIR

(EMERGENCY) SHUT OFF

3/4" ID AIR HOSE

IN-LINE OILER/LUBRICATOR

CONSTRUCTION TOOL