IRN37 - 160K - CC & IRN50 - 200H -CC & IRN75 - 160K - 2S & IRN100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

76

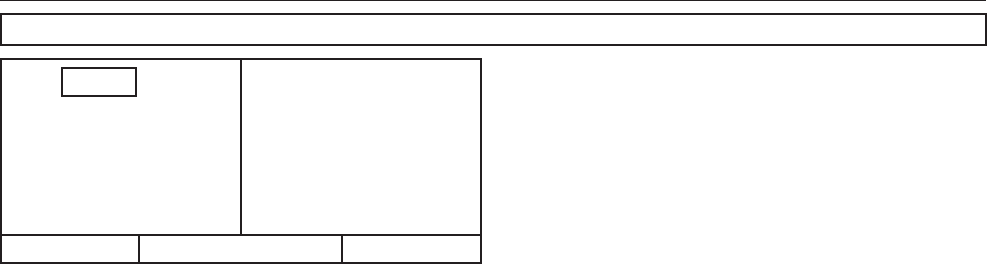

9.0 OPERATING INSTRUCTIONS

9.11 ENERGY STATUS MESSAGES

100 PSI

READY TO START

−ENERGY STATUS−

AVERAGE PACKAGE kW

HRS

AVERAGE % CAPACITY−

−AVERAGE CAPACITY

STATUS MAIN MENU SELECT

The Energy Status display can be selected by pressing the ENERGY

STATUS button. The following items and their present values will

be displayed on the right side of the screen by pressing the up and

down arrows.

AVERAGE PACKAGE kW HOURS − This displays the average

package kW per hour for the time period that was started by

selecting the reset averaging setpoint. This value includes the

blower power usage.

AVERAGE % CAPACITY − Displays the compressor’s average

percent capacity for the time period that was started by selecting

the reset averaging setpoint. The value is determined by taking the

average package kW per hour, removing the blower power usage

and then dividing that number by the motor kW per hour for that

size of compressor at 100% capacity.

AVERAGE CAPACITY − Displays the compressor’s average capacity

in cfm or m3 for the time period that was started by selecting the

reset averaging setpoint.

ENERGY COST − Displays the energy cost of the compressor for

the time period that was started by selecting the reset averaging

setpoint. This is calculated by multiplying the kW hours of the motor

and the blower by the energy rate.

ENERGY SAVINGS − Displays the energy savings of the compressor

for the time period that was started by selecting the reset averaging

setpoint as compared to a conventional compressor. This value is

determined by calculating how much a conventional compressor

motor would cost to operate at the same average capacity and then

subtracting the motor energy cost of the Nirvana compressor from

it. It is assumed that the blower cost is the same in both packages.

LIFETIME ENERGY SAVINGS − Displays the lifetime energy savings

of the compressor at the existing energy rate and at the average

percent capacity as compared to a conventional compressor.