IRN37 - 160K - CC & IRN50 - 200H & IRN75 - 160K - 2S & IRN - 100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

85

10.0 MAINTENANCE

Separator element change procedure for N250/

300H−2S

Disconnect the scavenge tube at the airend.

Loosen the fitting that holds the scavenge tube into

the tank and withdraw the tube assembly

Disconnect the piping from the tank cover. Tag the

lines if required.

Use a suitable wrench and remove the bolts that

hold the tank cover in position. Remove cover by

lifting up and away.

Carefully lift the separator element up and out of the

tank. Discard the faulty element.

Clean the gasket surface on both the tank and its

cover. Exercise care to prevent pieces of the old

gasket from falling down into the tank.

Check the tank to be absolutely certain that no

foreign objects such as rags or tools have been

allowed to fall into the tank. Install replacement

element down into the tank after checking the new

element gaskets for possible damage. Center the

element up within the tank.

Place the tank cover in its correct position and

install bolts. Tighten the bolts in a cross−pattern to

prevent over−tightening one side of the cover. An

improperly tightened cover will likely result in a leak.

Tank cover bolt torque values

250−300 HP

3/4−10 UNC

210ft−lb. (285 n−M)

Inspect tank scavenge screen and orifice. Clean if

necessary following instructions in Section 4.7.

Install scavenge tube down into the tank until the

tube just touches the separator element and then

raise it 1/8inch (3.2 mm). Tighten fittings.

Install the regulation lines in their original position.

Start unit, check for leaks, place in service.

RECOMMENDED BOLT TIGHTENING

CROSS PATTERN

250 − 300 HP

Scavenge screen clean/check procedure

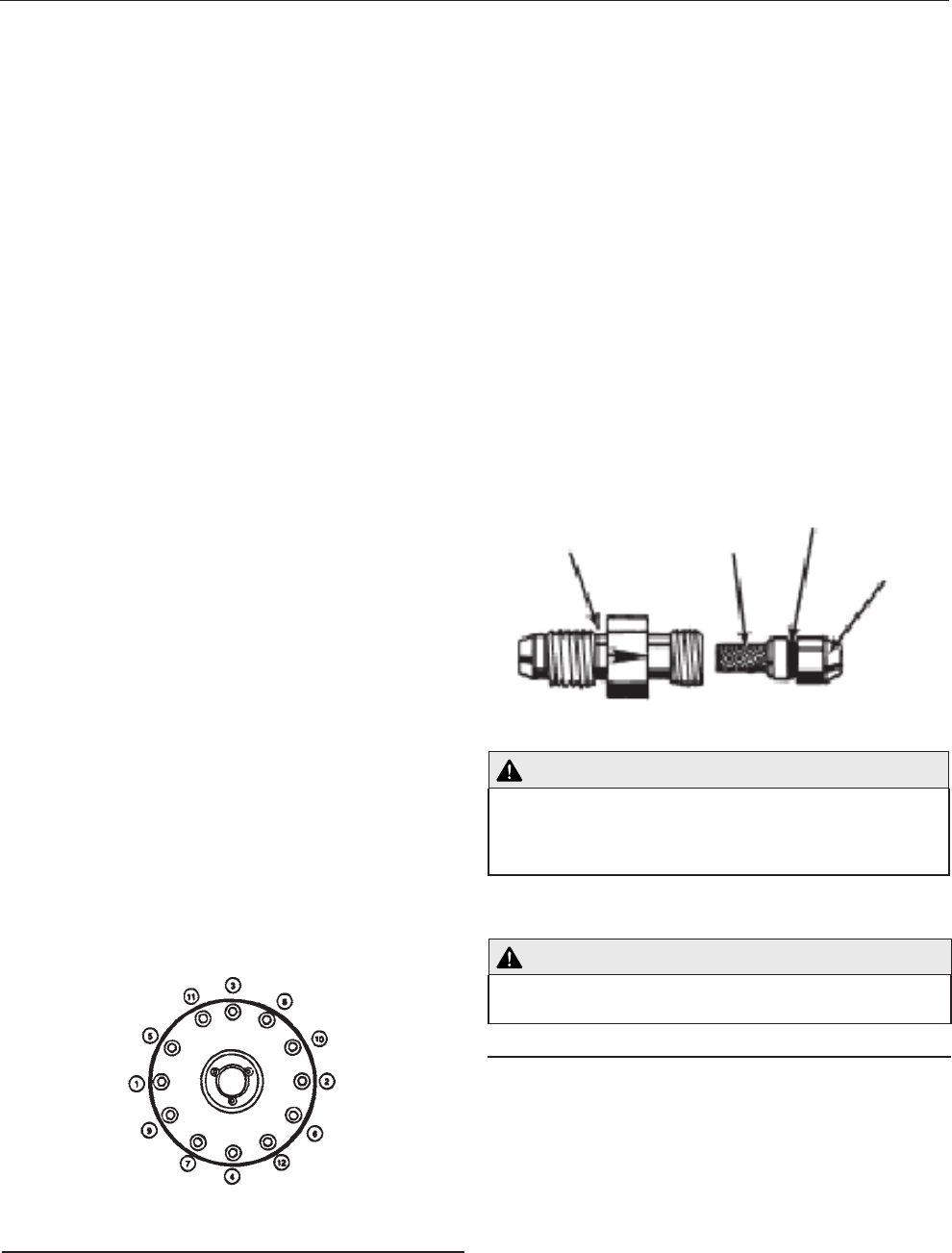

The screen/orifice assemblies are similar in appearance to

a straight tubing connector and will be located between

two pieces of 1/4 inch O.D. scavenge line tubing.

•

•

•

•

•

•

•

•

•

•

•

•

•

The main body is made from 1/2 inch hexagon

shaped steel and the diameter of the orifice and a

direction−of−flow arrow is stamped in flat areas of the

hexagon.

A removeable screen and orifice is located in the exit end

of the assembly. (see figure) and will require clearing as

outlined in the Maintenance Schedule Section 10.2.

To remove the screen/orifice, disconnect the scavenge

line tubing from each end. Hold the center section firmly

and use a pair of pliers to gently grasp the exit end of

the assembly that seals against the scavenge line tubing.

Pull the end out of the center section while using care to

prevent damage to the screen or sealing surfaces.

Clean and inspect all parts prior to reinstallation.

When the assembly is installed, confirm the direction of

flow to be correct. Observe the small arrow stamped in

the center section and ensure the direction flow to be

from the separator tank to the airend.

ORIFICE

SCREW HOUSING

SCREEN

O−RING

SEPARATOR TANK SCAVENGE SCREEN/ORIFICE

WARNING

Unscrew the jacking bolt sufficiently to ensure that

the cover can be fully tightened down without im-

parting any stress onto the jacking points. Tighten

down the cover setscrews.

Start the compressor and check for leaks and

coolant level.

CAUTION

Do not use any form of sealant on either the separa-

tor tank or the separator tank cover faces.

Separator tank / Pressure system

At 2000 hour intervals, inspect the external surfaces of

the airend and separator tank, including all fittings, for

visible signs of impact damage, excessive corrosion and

abrasions. When changing the separator element inspect

the internal components and surfaces. Any suspect parts

should be replaced before the compressor is put back

into service.

The separator tank should also be tested and inspected

in accordance with any national or local codes that may

exist.

•