22

Maintenance

Blade Care

Blades are extremely sharp!

Use caution when cleaning

or changing. Failure to comply may cause

serious injury!

!

The condition of the blades will affect the

precision of the cut. Observe the quality of

the cut that the machine produces to check

the condition of the blades.

!

Dull blades will tear, rather than cut the

wood fibers and produce a fuzzy

appearance.

!

Raised grain will occur when dull blades

pound on wood that has varying density. A

raised edge will also be produced where the

blades have been nicked.

When gum and pitch collect on the blades,

carefully remove with a strong solvent. Failure to

remove gum and pitch build up may result in

excessive friction, blade wear and overheating.

When blades become dull, touch up blades. See

Sharpening the Knives.

Sharpening the Knives

Blades are extremely sharp! Use caution

when handling. Failure to

comply may cause serious

injury!

1. Disconnect the machine from the power

source.

2. Remove the blade guard and belt cover.

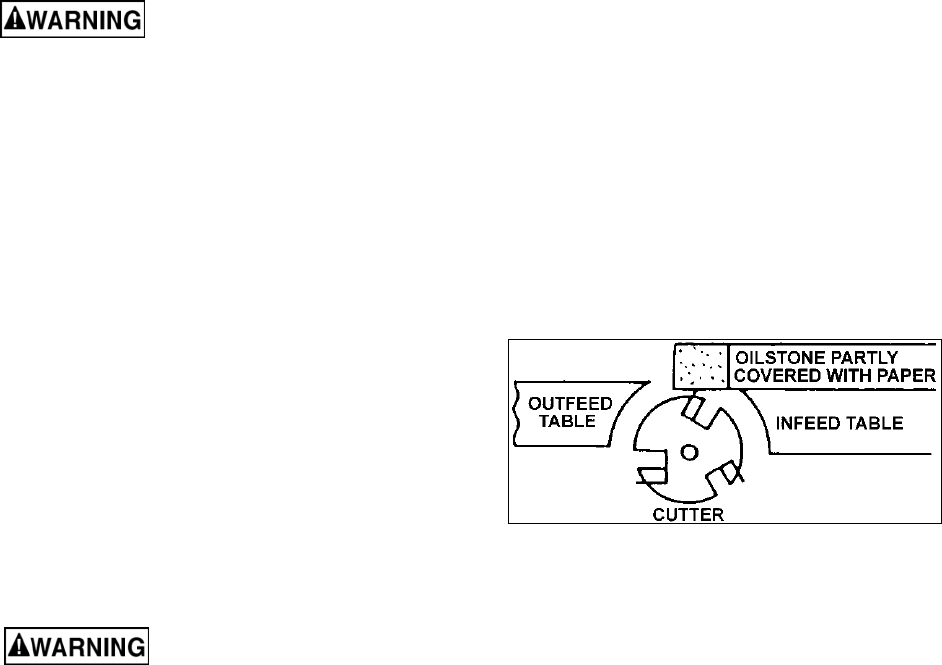

3. To protect the infeed table from scratches,

partially cover the sharpening stone with

paper (Figure 24).

4. Lay the stone on the infeed table.

5. Lower the infeed table and turn the

cutterhead by turning the cutterhead pulley.

The infeed table height is set properly when

the stone's surface is flush with the knife

bevel.

6. Keep the cutterhead from rotating by

grasping the cutterhead pulley while sliding

the stone back and forth across the table.

7. Take the same amount of passes for all two

blades.

When the blades have been sharpened and still

are not cutting efficiently, trying to touch up the

blades further will only cause the formation of a

second beveled edge. When this starts to

happen, it is time to replace blades with another

set. It is recommended to keep a second set of

blades on hand so that they may be installed

while the first set is being professionally

sharpened.

Figure 24

Lubrication

!

Use a good grade of light grease on the

steel adjusting screws located in the raising

and lowering mechanisms of the work

tables.

The cutterhead ball bearings are lifetime

lubricated and need no further care.