15

Sanding and Finishing

Leaving clean cuts will reduce the amount of

sanding required. Begin with a fine sandpaper (120

grit or finer). Coarser sandpaper will leave deep

scratches that are difficult to remove, and dull crisp

details. Fold the sandpaper into a pad; do not wrap

sandpaper around your fingers or the workpiece.

To apply a finish, the workpiece can be left on the

lathe. Turn off lathe and use a brush, or cloth to

apply the finish. Remove excess finish before

restarting lathe. Allow drying and sanding again

with 320 or 400 grit sandpaper. Apply additional

coats of finish and buff.

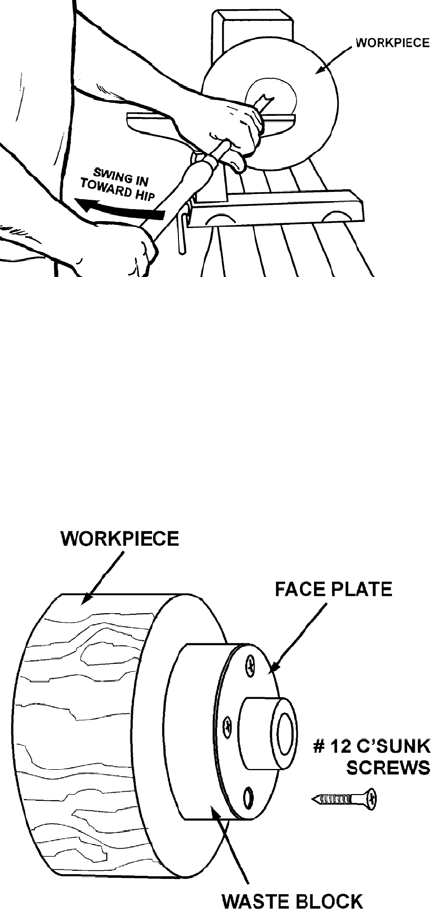

Face Plate and Bowl Turning

Face plate turning is normally done on the inboard

side of the headstock over the bed see Figure 19.

You must pivot the headstock 180° for larger

workpieces.

Mounting Stock

Use of a face plate is the most common method for

holding a block of wood for turning bowls, and

plates.

1. Select stock at least 1/8" to 1/4" larger than the

dimension on the desired finished workpiece.

2. True one surface of the workpiece for mounting

against the face plate. It is best to leave extra

stock against the faceplate that can be cut off

when the workpiece is finished.

3. Using the faceplate as a template, mark the

location of the mounting holes, and drill pilot

holes of the appropriate size. If the mounting

screws on the faceplate interfere with the

workpiece, a waste block can be mounted to

the faceplate and then the waste block

mounted to the workpiece by gluing or screw-

ing, see Figure 20.

4. Both waste block and workpiece should have

good flat surfaces.

5. Push in on the spindle lock and thread face

plate and workpiece onto the spindle. Tighten

setscrews in the faceplate when secure.

Figure 19

Figure 20