4/29/03

Manual V-16, V-24, VH-24, V-40 & VH-40 20 – Section I

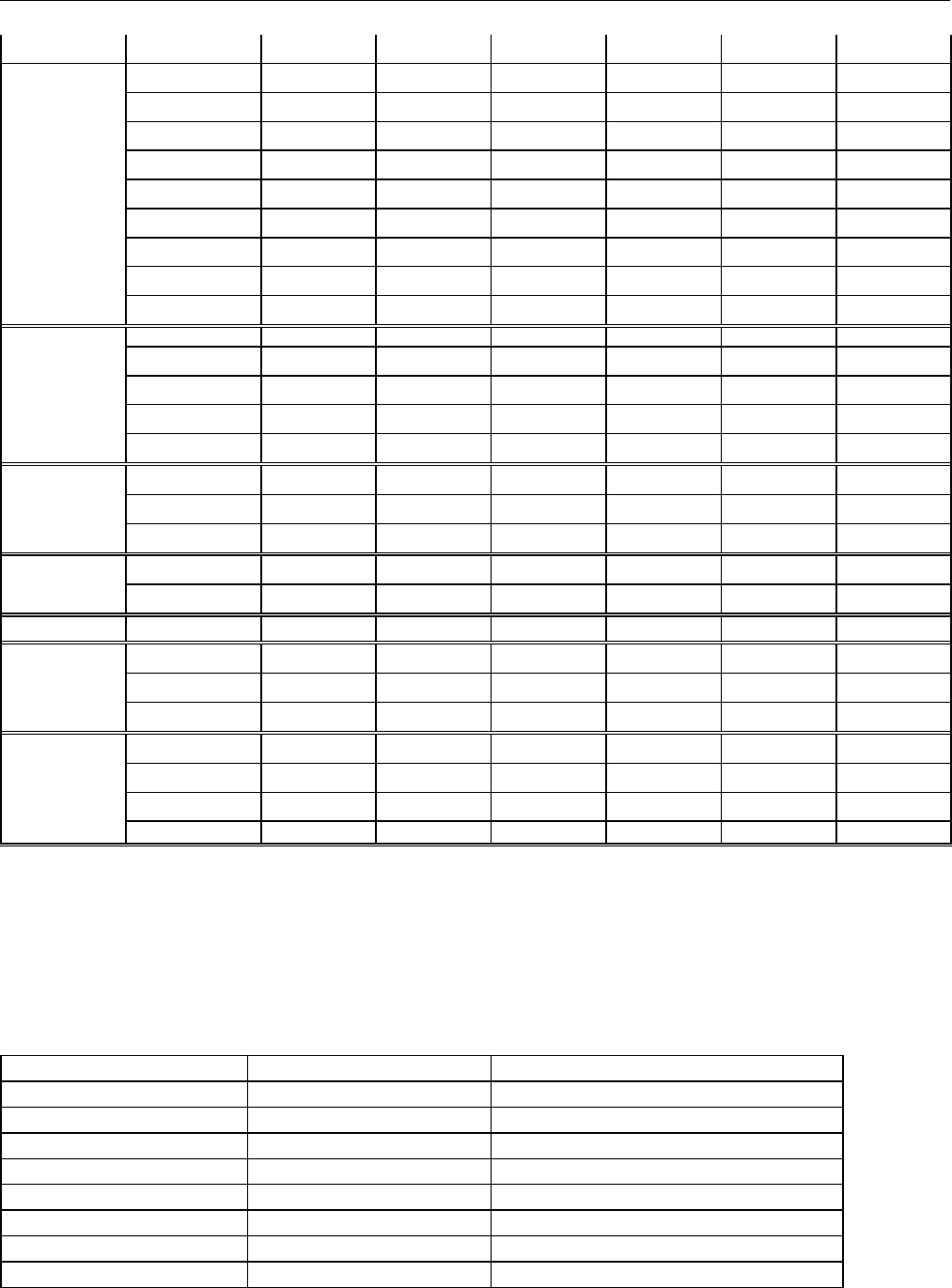

MATERIAL ALLOY 1/2" 1" 2" 4" 7" 12"

INCONEL 751,X750 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

NICKEL BASE WASPALOY fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

ALLOY MONEL K500 fpm 74 sipm 1 fpm 72 sipm 1 fpm 70 sipm 2 fpm 65 sipm 3 fpm 59 sipm 3 fpm 51 sipm 3

(*HASTELLOY) INCOLOY 901,903,926 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

INCONEL 600,718 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NI-SPAN-C 902 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NIMONIC 263 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

RENE 41,UDIMET 500 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NIMONIC 75 fpm 57 sipm 1 fpm 56 sipm 1 fpm 54 sipm 2 fpm 50 sipm 2 fpm 45 sipm 2 fpm 39 sipm 2

ASTM A220 (50005) fpm 273 sipm 4 fpm 267 sipm 5 fpm 257 sipm 7 fpm 239 sipm 10 fpm 216 sipm 11 fpm 187 sipm 12

CAST IRONS ASTM A220 (60004) fpm 193 sipm 3 fpm 189 sipm 4 fpm 182 sipm 5 fpm 169 sipm 7 fpm 153 sipm 8 fpm 132 sipm 8

PEARLITIC ASTM A220 (70003) fpm 165 sipm 2 fpm 161 sipm 3 fpm 155 sipm 5 fpm 144 sipm 6 fpm 131 sipm 7 fpm 133 sipm 7

MALLEABLE ASTM A220 (80002) fpm 142 sipm 2 fpm 139 sipm 3 fpm 134 sipm 4 fpm 125 sipm 5 fpm 113 sipm 6 fpm 97 sipm 6

ASTM A220 (90001) fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

ASTM A436 (1B) fpm 170 sipm 2 fpm 167 sipm 3 fpm 161 sipm 5 fpm 149 sipm 6 fpm 135 sipm 7 fpm 117 sipm 7

GRAY IRON ASTM A436 (2) fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 125 sipm 7 fpm 109 sipm 7

AUSTENITIC ASTM A436 (2B) fpm 142 sipm 2 fpm 139 sipm 3 fpm 134 sipm 4 fpm 125 sipm 5 fpm 133 sipm 6 fpm 97 sipm 6

DUCTILE ASTM A439 (D-2) fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

AUSTENITIC ASTM A439 (D2-B) fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

MALLEABLE ASTM A47(50&53ksi) fpm 341 sipm 4 fpm 334 sipm 6 fpm 321 sipm 9 fpm 299 sipm 13 fpm 271 sipm 14 fpm 234 sipm 14

ASTM A48 (20ksi) fpm 261 sipm 3 fpm 256 sipm 5 fpm 246 sipm 7 fpm 229 sipm 10 fpm 207 sipm 11 fpm 179 sipm 11

GARY IRON ASTM A48 (40ksi) fpm 204 sipm 3 fpm 200 sipm 4 fpm 193 sipm 6 fpm 179 sipm 8 fpm 162 sipm 8 fpm 140 sipm 9

ASTM A48 (60ksi) fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

ASTM A536 (60-40-18) fpm 409 sipm 5 fpm 401 sipm 8 fpm 396 sipm 11 fpm 359 sipm 15 fpm 325 sipm 17 fpm 280 sipm 17

DUCTILE ASTM A536 (88-55-06) fpm 273 sipm 4 fpm 267 sipm 5 fpm 257 sipm 7 fpm 239 sipm 10 fpm 216 sipm 11 fpm 187 sipm 12

ASTM A536 (100-70-03) fpm 210 sipm 3 fpm 206 sipm 4 fpm 198 sipm 6 fpm 184 sipm 8 fpm 167 sipm 9 fpm 144 sipm 9

ASTM A536 (120-90-02) fpm 136 sipm 2 fpm 134 sipm 3 fpm 129 sipm 4 fpm 120 sipm 5 fpm 108 sipm 6 fpm 93 sipm 6

RATE REDUCTION FOR HARD MATERIALS

Below is a matrix for speed reduction for hard materials. Find the material hardness, either Rockwell

(Rc) or Brinell (Bhn), and reduce both band speed and cutting rate by the percentage shown.

HARDNESS (Rc) HARDNESS (Bhn) SPEED / CUTTING

Rockwell Brinell

RATE REDUCTION

Up to 20 226 0%

22 237 5%

24 247 10%

26 258 15%

28 271 20%

30 286 25%

32 301 30%

34 319 33%

36 336 35%