4/29/03

Manual V-16, V-24, VH-24, V-40 & VH-40 21 – Section I

38 353 40%

HYDRAULIC FEED TABLE

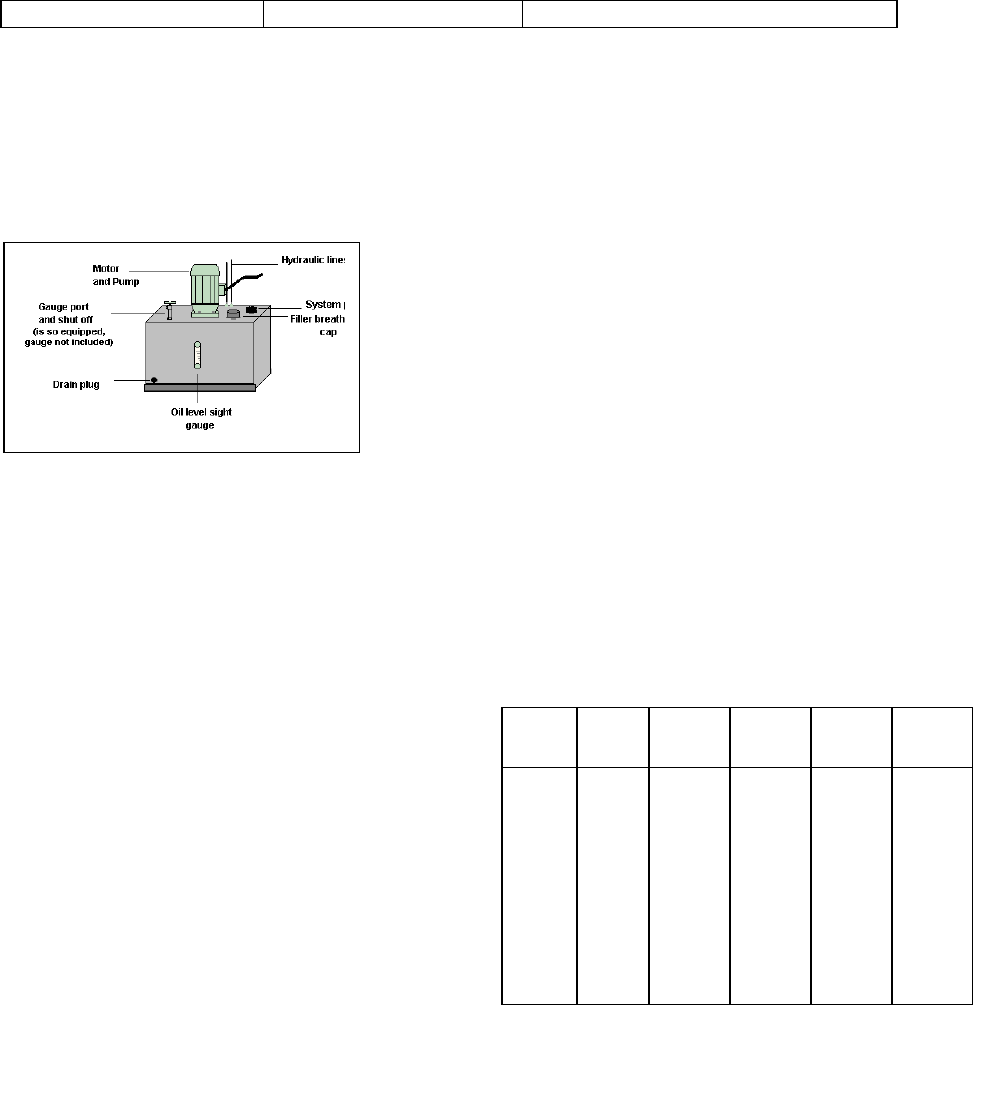

Machines equipped with a hydraulic feed table (VH models) have a pumping unit in the base. The

system has an adjustable relief valve, which is factory preset at 400 p.s.i. This setting may be reduced

to afford greater sensitivity for cutting soft or thin materials. Pressures may be lowered by turning the

square nut located on the top right hand side of the reservoir. (See below graphic) The systems oil level

must be checked periodically to assure the oil levels are maintained at the full level of the sight glass.

The feed table regulator will provide a smooth movement to the

table. If the feed appears to be intermittent it is probably due to

air in the system. This is normally exhausted by running the table

in and out a few times.

WELDING INSTRUCTIONS

GENERAL DESCRIPTION

Note: Always wear eye protection when using this welder or grinder!

Your Dake vertical band saw is equipped with a “resistance-type” butt welder. The two clamp jaws of

the welder hold the blade ends together. When the welding start knob is turned fully clockwise past the

zero setting, electric current flows through the blade ends creating enough heat to soften and join them.

Note: This welder is suitable to weld

Metal blades 3 x 0.5 - 25 x 0.8mm

bi-metal blades 6 x 0.9 - 25 x 0.9mm

This welder should not be used for welding

2% and 3% tungsten-alloyed metal cutting

blades or HSS blades.

The approximate valves for bi-metal blades

are indicated in the matrix in the next

column

.

Note: * The weld current step and

upsetting pressure step have to be

increased with some saw manufactures.

The saw blade has to be metallically clean

and no tooth may enter into the welding

seam.

1. PREPARATION OF BLADE

Before welding the blade ends should be cleaned or rubbed with emery cloth on both sides of the blade

to a length of 1”, until they are metallically clean over the enter width.

BANDSAW WELDING

CURRENT

UPSETTING

PRESSURE

UPSETTING

WAY

ANNEALING ANNEALING

mm step *) step *) mm COLOR TIME SEC.

6 x 0.9 1 - 2 1 2.5 DARK RED 15

10 x 0.9 1 - 2 1 3.0 DARK RED 15

12 x 0.6 1 - 2 1 3.0 DARK RED 15

12 x 0.9 1 - 2 1 3.0 DARK RED 15

13 x 0.7 1 - 2 1 - 2 3.0 DARK RED 15

16 x 0.7 1 - 2 1 - 2 3.0 DARK RED 15

19 x 0.9 1 - 2 1 - 2 3.0 DARK RED 15

25 x 0.9 1 - 2 1 - 2 3.5 DARK RED 15