Kramer Electronics Ltd.

13

removed in the same way by performing proper clamping. To clamp the DC level to -1V or 0V select the

desired level using the -1V/0V switch located on the machine's rear panel.

8 TAKING CARE OF YOUR PROCESSOR

Do not locate your processor in an environment where it is susceptible to dust or moisture and temperature

and humidity may be excessive. All of these may damage the electronics, and cause erratic operation or

failure. Do not clean your processor with abrasives or strong cleaners. Doing so may remove or damage

the finish, or may allow moisture to build up. Take care not to allow dust or particles to build up inside

unused or open connectors.

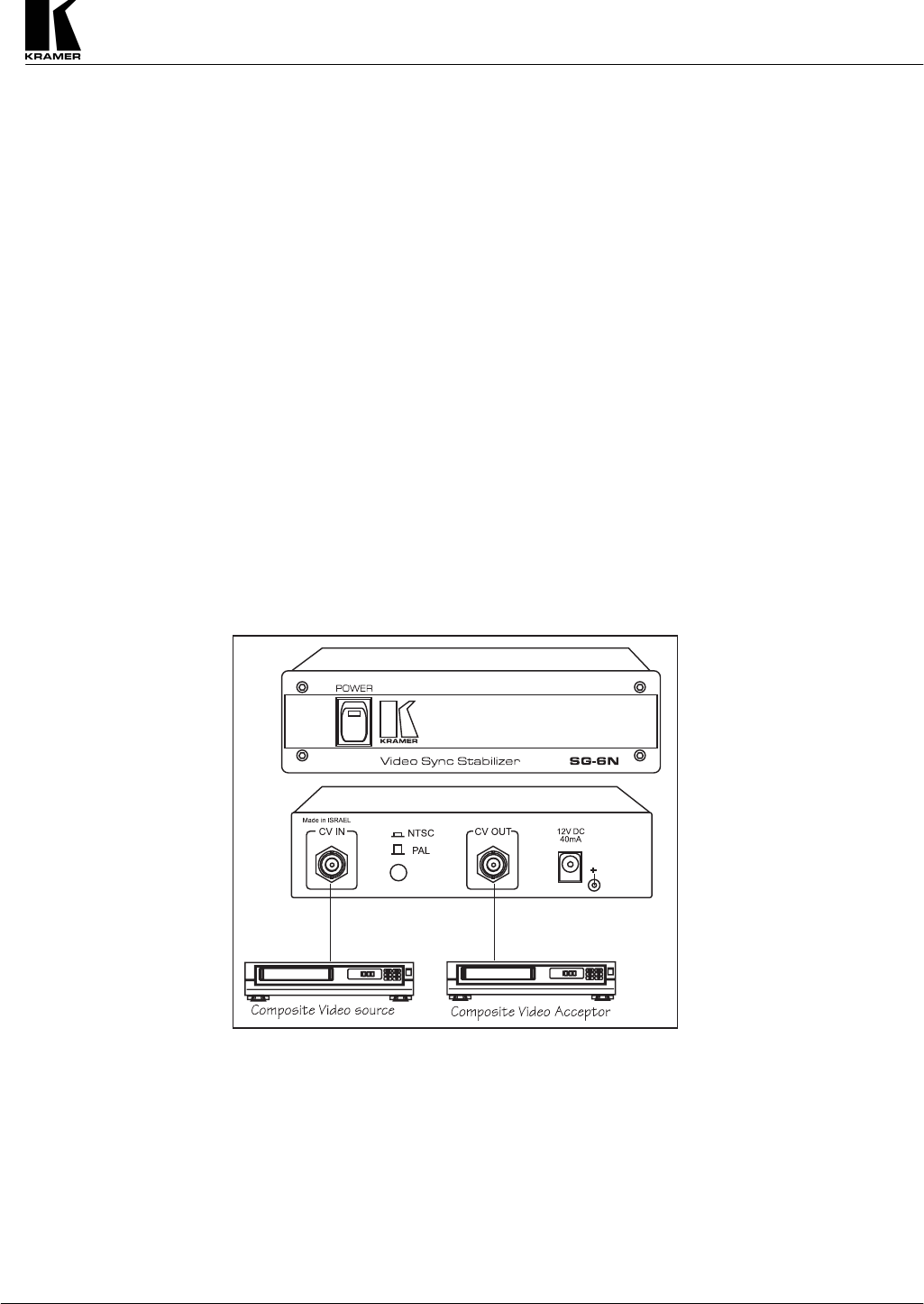

9 TYPICAL APPLICATIONS

9.1 Stabilizing the Video Sync

As the sync information is vital for video image stability on the screen, deterioration or loss of the sync

signals affects image stability. Both Horizontal and Vertical sync signals are crucial for image stability and

proper image centering on the screen. When the sync signals are damaged during transmission or recording

they may be recovered by a sync restoring device. Another problem of sync compatibility is a result of the

many standards for transferring the sync information with the signal: sync signals may come in analog

form, as a composite sync signal, in digital form, either as composite or separate Horizontal and Vertical,

positive direction or negative. The sync signals may be part of the luminance signals or ride on a video

component signal such as the “Green” signal. To solve this compatibility problem, special devices such as

sync format converters are needed. Typical video sync stabilization is described in Figure 8: A corrupted

video signal is applied to a Video Sync Stabilizer's input (SG-6N in this case). The SG-6N removes of

unwanted interference and signal distortions and the restored signal is outputted to an appropriate acceptor.

Figure 8: Stabilizing the Video Sync