Permissible

Current in

@120 VAC *

80**

60**

46**

36

20

0

B-6

OPERATION

B-6

ARC GOUGING

The RANGER 305G can be used for limited arc goug-

ing. For optimal performance, set the MODE switch to

CC-STICK and the ARC CONTROL to +10.

Set the CONTROL knob to adjust output current to the

desired level for the gouging electrode being used

according to the ratings in the following table.

Carbon Diameter

Current Range (DC, electrode

positive)

1/8" 60-90 Amps

5/32" 90-150 Amps

3/16" 200-250 Amps

AUXILIARY POWER:

Start the engine and set the IDLER control switch to

the desired operating mode. Full power is available

regardless of the welding control settings providing no

welding current is being drawn.

The auxiliary power of the RANGER 305G consists of

two 20 Amp-120 VAC (5-20R) duplex receptacles and

one 50 Amp 120/240 VAC (14-50R) receptacle. The

240 VAC receptacle can be split for single phase 120

VAC operation.

The auxiliary power capacity is 10,500 watts Peak,

9500 Watts continuous of 60 Hz, single phase power.

The auxiliary power capacity rating in watts is equiva-

lent to volt-amperes at unity power factor. The max

permissible current of the 240 VAC output is 40 Amps.

The 240 VAC output can be split to provide two sepa-

rate 120 VAC outputs with a max permissible current

of 40 Amps per output to two separate 120 VAC

branch circuits (these circuits cannot be paralleled).

Output voltage is within ± 10% at all loads up to rated

capacity. All auxiliary power is protected by circuit

breakers.

The 120 V auxiliary power receptacles should only be

used with three wire grounded type plugs or approved

double insulated tools with two wire plugs. The current

rating of any plug used with the system must be at

least equal to the current capacity of the associated

receptacle.

NOTE: The 240 V receptacle has two circuits, each of

which measure 120 V to neutral but are of opposite

polarities and cannot be paralleled.

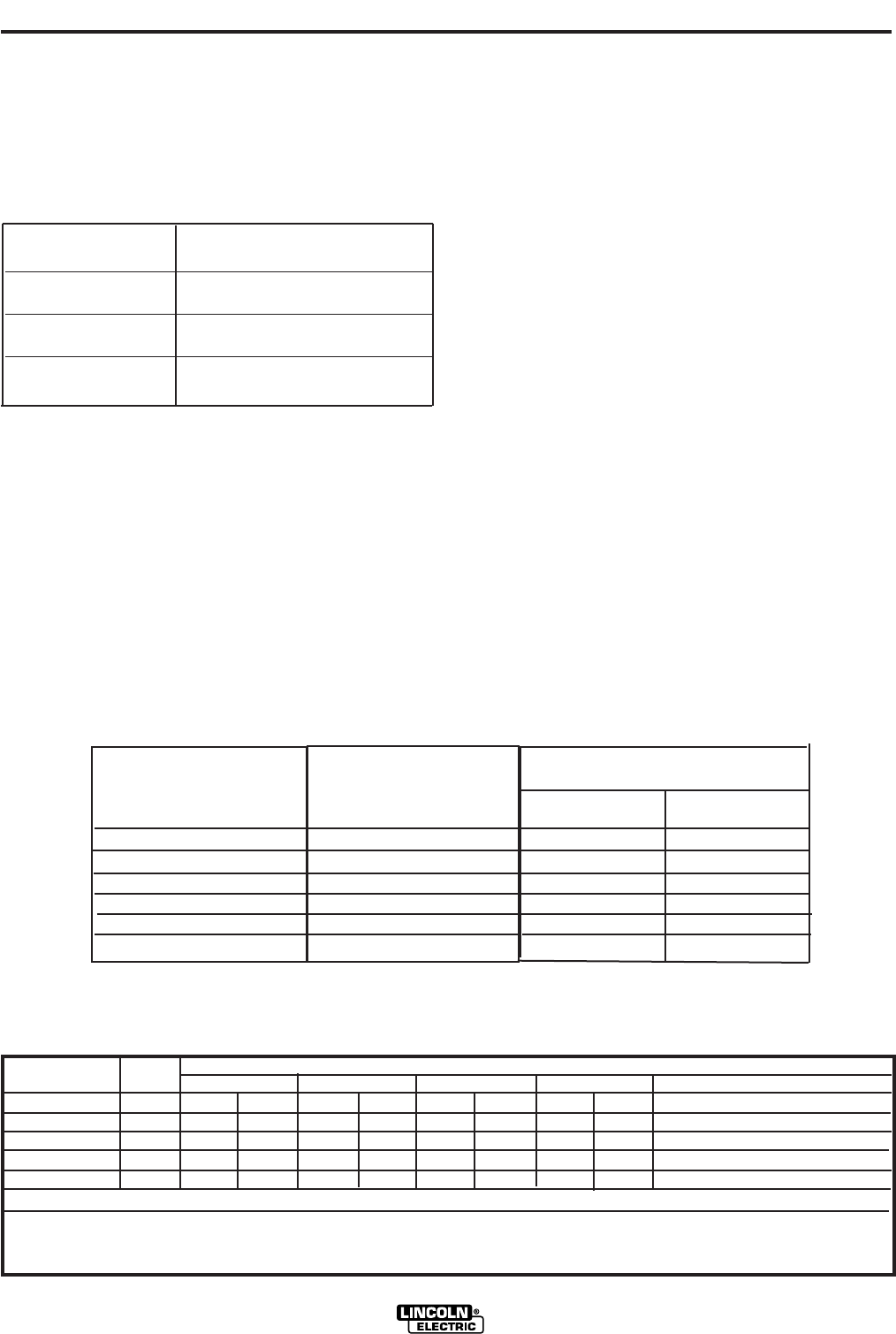

Simultaneous Welding and Auxiliary Power Loads

The above auxiliary power ratings are with no welding

load. Simultaneous welding and power loads are

specified in the following table. The permissible cur-

rents shown assume that current is being drawn from

either the 120 VAC or 240 VAC supply (not both at the

same time).

RANGER 305G

Welding

Output-Amps

0

100

150

200

250

300

Permissible Power-Watts

(Unity Power Factor)

9500

7100

5600

4200

2300

0

Auxiliary

-Amps

@ 240 VAC

40

30

23

18

10

0

* Each duplex receptacle is limited to 20 amps.

** Not to exceed 40A per 120 VAC branch circuit when splitting the 240 VAC output.

RANGER 305G Simultaneous Welding and Power Loads

RANGER 305G Extension Cord Length Recommendations

(Use the shortest length extension cord possible sized per the following table.)

Current

(Amps)

15

20

15

20

40

Voltage

Volts

120

120

240

240

240

Load

(Watts)

1800

2400

3600

4800

9500

30

60

(9)

(18)

40

30

75

60

(12)

(9)

(23)

(18)

75

50

150

100

50

(23)

(15)

(46)

(30)

(15)

125

88

225

175

90

(38)

(27)

(69)

(53)

(27)

175

138

350

275

150

(53)

(42)

(107)

(84)

(46)

300

225

600

450

225

(91)

(69)

(183)

(137)

(69)

Maximum Allowable Cord Length in ft. (m) for Conductor Size

Conductor size is based on maximum 2.0% voltage drop.

14 AWG 12 AWG 10 AWG 8 AWG 6 AWG 4 AWG