D-5

TROUBLESHOOTING

D-5

Observe all Safety Guidelines detailed througout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

FUNCTION PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED

COURSE OF ACTION

H.Machine trips off when under no

load or makes excessive noise

like it is loaded.

I. Variable or sluggish welding arc.

J. Welder will not shut off.

K. Current control on machine not

functioning.

1. Power bridge rectifier may have

a shorted diode or SCR.

2. Short in the transformer.

3. Fan hitting vertical baffle.

1. Poor work or electrode cable

connection.

2. Current too low.

3. Welding leads too small.

4. Open SCR or diode in power

rectifier bridge.

5. Control circuit problems.

1. Input contactor contacts frozen.

1. Current control switch in wrong

position.

2. Current control switch defective.

3. Current control potentiometer

defective.

4. Lead or connection in control

circuit open.

5. Defective control or circuit

boards.

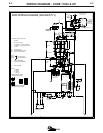

1. Refer to Power Hybrid Bridge

Checking Procedure. See

Troubleshooting Procedures –

Checking Snubber Circuit and

Power Rectifier Bridge Assembly.

2. Repair.

3. Clear the fan.

1. Check and clean cable connec-

tions.

2. Check recommended currents

for rod type and size.

3. See Troubleshooting Procedures

– Fault Protection Operation.

4. Check per Power Hybrid Bridge

Procedures. See

Troubleshooting Procedures –

Checking Snubber Circuit.

5. See Troubleshooting

Procedures.

1. Replace input contactor.

1. Place switch in “machine” posi-

tion.

2. See Troubleshooting Procedures

– Toggle Switch Check.

3. See Troubleshooting Procedures

– Checking Current Control

Rheostat.

4. Repair or connect.

5. See Troubleshooting Procedure

– Power Silicon Controlled

Rectifier.

E500