E500

E-2

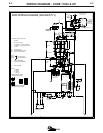

WIRING DIAGRAM - CODE 11042 & UP

E-2

ELECTRICAL SYMBOLS PER E1537

LEGEND

L1 DC OUTPUT FILTER

R1

R2

R3

TO GROUND

PER

NATIONAL

ELECTRICAL

CODE

H3

H2

H1

X2

X1

T2

TO SUPPLY LINES

DIAL SELECTOR SWITCH

SCR1-D1

SCR2-D2

SCR3-D3

D4

SCR AND DIODE

RECTIFIER BRIDGE

T1

T2

MAIN TRANSFORMER

CONTROL TRANSFORMER

1CR

INPUT STARTER

( DASHED ITEMS ON WIRING

DIAGRAM ARE OPTIONAL )

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF BOARD)

A

BC

10K OHM POT., OUTPUT CONTROL

10K OHM POT., ARC FORCE CONTROL

30 OHM

SW1

SW2

SW3

POWER SWITCH

MACHINE/REMOTE SWITCH

L1

D4

D1

D2

D3

SCR1

SCR2

SCR3

R3

204

204

204

205

SHUNT

CONTROL

P.C.

BOARD

SW1

PILOT LIGHT

231

235

235

232

W

77

76

75

204

204

214

75

210

211

R1

SW2

R2

204

208

209

224

-

+

217

217

A

A

115 V

201

202

203

13 14 15

7

8

9

S

S

S

10 11 12

1

2

3

456

66V

AUXILIARY COILS

BOTTOM PRIMARY

TOP PRIMARY

T1

X1

X2

X3

SEC SEC SEC

A

CHOKE

THERMOSTAT

SECONDARY

THERMOSTAT

233

231

204

1CR

L1

L2

L3

RECONNECT PANEL SHOWN

TO PRIMARY COILS

H4

234 235

FAN

HIGH TEMP LIGHT

G2

G3

204

+

-

G1

G2

G3

204

220

211

210

213

77

212

76

SW3

A = AMBER

G = GREEN

W = WHITE

Y = YELLOW

COLORS

235

232

66V

66V

16

17

18

6

15

5

14

4

13

1

2

3

7

8

9

TAPE UP

SEPARATELY

TO PROVIDE

AT LEAST

600 VOLTS

INSULATION

{

18

16

17

CONNECTED FOR 230V

1

8

5

6

7

4

3

2

1

5

6

4

3

2

1

2

4

3

1

2

204

209

208

217

CONTROL

P.C.

BOARD

1

2

3

4

5

6

7

8

214

75

213

212

{

{

J2

J4

J1

2134 21

REMOTE CONTROL

RECEPTACLE

12345678

{

J5

SNUBBER BOARD

226

224

204

226

220

225

221

222

223

G1

RECTIFIER

BRIDGE

201

202

203

204

201A

203A

J3

6

3

2

1

5

4

{

L11467

A

E500 WIRING DIAGRAM (230/460/575 V)

(SWITCH SHOWN IN

LOCAL POSITION)

235

66V

S

S

32B

31A

THERMOSTAT

FAN

THERMAL

287

A

MOTOR

GROUND STUD ON

OUTPUT PANEL

WHITE

WHITE

LINE

LOAD

HOT

LINE

LOAD

HOT

GROUND STUD ON

OUTPUT PANEL

WHITE

WHITE

LINE

LOAD

HOT

LINE

LOAD

HOT

31

32A

GFCI

15A

32