B-6

OPERATION

B-6

TIG

The BIG RED™ 600 can be used for Scratch-Start

of DC TIG welding applications.

Use the “Output Range Selector” and “Output

Control Adjustments” to set the desired current. To

initiate a weld, the tungsten electrode is then

scratched on the work which establishes the arc. To

stop the arc, simply lift the TIG torch away from the

work piece. The tungsten may then be scratched on

the work piece to restrike the arc.

If a high frequency start is desired, the K930-2 TIG

Module can be used with the BIG RED™ 600. The

BIG RED™ 600 and any high frequency generating

equipment must be properly grounded. See the

K930-2 TIG Module operating manuals for com-

plete instructions on installation, operation, and

maintenance.

When using the TIG Module, the OUTPUT control

on the BIG RED™ 600 is used to set the maximum

range of the CURRENT CONTROL on the TIG

Module or an Amptrol if connected to the TIG

Module.

BIG RED™ 600

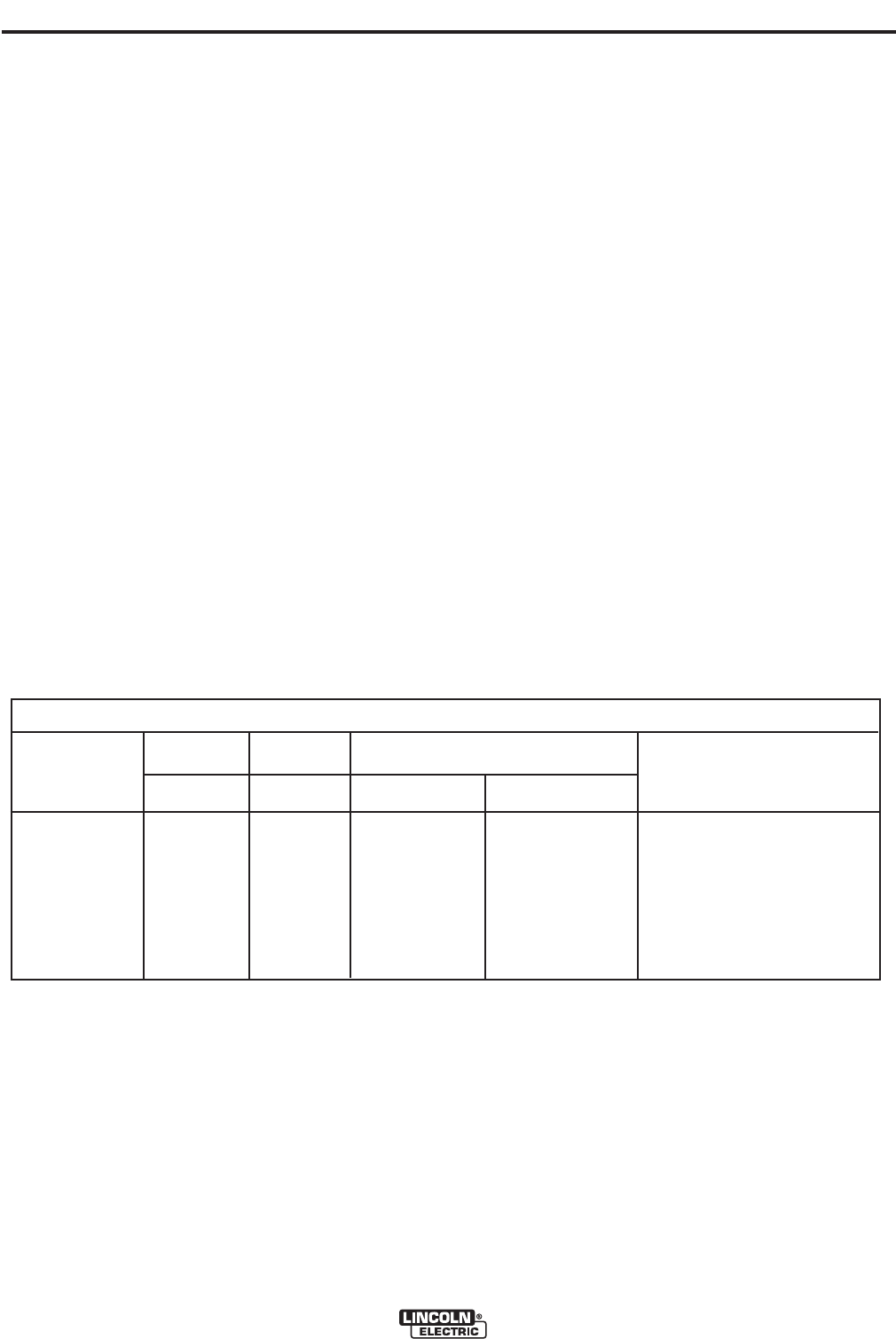

TYPICAL CURRENT RANGES

(1)

FOR TUNGSTEN ELECTRODES

(2)

Tungsten Electrode DCEN (-) DCEP (+) Approximate ArgonGas Flow TIG TORCH

Diameter in.(mm) Flow RateC.F.H. ( l /min.) Nozzle Size(4), (5)

1%, 2%Thoriated 1%, 2%Thoriated Aluminum Stainless Steel

Tungsten Tungsten

.010 (.25) 2-15 (3) 3-8 (2-4) 3-8 (2-4) #4,#5, #6

0.020 (.50) 5-20 (3) 5-10 (3-5) 5-10 (3-5)

0.040 (1.0) 15-80 (3) 5-10 (3-5) 5-10 (3-5)

1/16 (1.6) 70-150 10-20 5-10 (3-5) 9-13 (4-6) #5, #6

3/32 (2.4) 150-250 15-30 13-17 (6-8) 11-15 (5-7) #6,#7, #8

1/8 (3.2) 250-400 25-40 15-23 (7-11) 11-15 (5-7)

5/32 (4.0) 400-500 40-55 21-25 (10-12) 13-17 (6-8) #8,#10

3/16 (4.8) 500-750 55-80 23-27 (11-13) 18-22 (8-10)

1/4 (6.4) 750-1000 80-125 28-32 (13-15) 23-27 (11-13)

(1) When usedwith argon gas. The current rangesshown must bereduced whenusing argon/helium orpure helium shieldinggases.

(2) Tungsten electrodes areclassified asfollows by theAmerican Welding Society(AWS):

Pure EWP

1% Thoriated EWTh-1

2% Thoriated EWTh-2

Though notyet recognized bythe AWS, CeriatedTungsten is nowwidely acceptedas a substitute for2% Thoriated Tungsten inAC and DCapplications.

(3) DCEP isnot commonly usedin these sizes.

(4) TIG torchnozzle "sizes" arein multiples of1/16ths ofan inch:

# 4= 1/4 in. (6mm)

# 5= 5/16 in. (8 mm)

# 6= 3/8 in. (10mm)

# 7= 7/16 in. (11 mm)

# 8= _ in. (12.5 mm)

#10 =5/8 in. (16mm)

(5) TIGtorch nozzles aretypically madefrom alumina ceramic. Special applications mayrequire lava nozzles,which areless prone tobreakage, but cannotwithstand high temperatures

and highduty cycles.

TABLE B.3