OPERATING INSTRUCTIONS

To Set for Machine or Remote Control

The output can be controlled either at the wire feeder or

the DC-1500. When the NL Option Kit is installed, how-

ever, output is controlled only from the K775 Remote Con-

trol usually mounted at the wire feeder.

To adjust the output from the wire feeder, set the toggle

switch on the front of the DC-1500 to “Output Control

Remote”. To adjust the output using the DC-1500 “Output

Control” rheostat, set this switch to “Output Control at DC-

1500”.

To Set the Welder Output

With the toggle switch set to “Output Control at DC-1500”,

rotating the “Output Control” rheostat on the DC-1500

from 1 to 10 increases the machine output from minimum

to maximum. The same full range control is set from the

wire feeder or K775 when the toggle switch is set to “Output

Control Remote”.

Set the output as required by the welding procedures.

Mode Switch

The toggle switch labeled CV Innershield, CV submerged

arc, VV submerged arc, is used to select the proper welder

characteristics for the process being used.

NOTE: Some machines say ”VV” for variable voltage while

other machines use the terminology “CC” for constant cur-

rent.

The CV Innershield Mode permits the DC-1500 to produce

essentially a flat output characteristic that can be varied

from approximately 20 to 60 volts. In this position the dy-

namic characteristics of the machine under welding con-

ditions provides optimum welding characteristics for

Innershield welding and other open arc processes.

The CV Submerged Arc Mode also produces an essentially

flat output characteristics that can be varied from approxi-

mately 20 to 60 volts. The dynamic characteristics of the

CV Submerged Arc Mode are such that excellent submerged

arc welding can be obtained for most procedures that pre-

viously required a constant current type power source.

The VV Submerged Arc Mode permits the DC-1500 to pro-

duce a constant current output characteristic through the

range of 200A-28V to 1500A-60V with an open circuit volt-

age of 45 to 98 volts. Although almost all submerged arc

welding can now be done in the CV mode, the VV mode

is available for those procedures where VV (CC) may still

be desirable.

Set-up for Various Processes

Selection of mode switch position — There are several gen-

eral rules to follow in the selection of the mode switch posi-

tion.

1. Use the CV Innershield mode for all Innershield weld-

ing.

2. Use the CV Submerged Arc mode for most submerged

arc welding. However, some high speed welding pro-

cedures may perform better on the CV Innershield

mode.

3. The VV (CC) mode is available for high current, large

puddle submerged arc procedures that cannot be done

as well with the constant voltage mode.

4. Air Carbon Arc Gouging or Cutting — For air carbon

arc gouging, the constant voltage Innershield mode is

used with the output control set between 4 and max.

depending on the application, carbon size, etc. Up to

1

/

2

” carbons, start with the machine control set at 4 and

increase as required for long cable lengths. With

1

/

2

”

and

5

/

8

” carbons, short (100’) cable lengths can lead to

occasional tripout of the protection circuit when the

carbon is shorted to the work. Cutting back the output

setting will reduce the short circuit current and mini-

mize tripping. Longer cable lengths do an even better

job since this also reduces the short circuit current but

even more significantly permits raising the open circuit

voltage (by increasing control setting) for smoother op-

eration. See the table below for optimum cable size and

length.

If ever longer leads are used and the output control is

already set on max., the unit has reached its maximum

air carbon arc capability.

3

/

4

” carbons are not recommended for use with the

DC-1500 because the high surge currents that occur

with this diameter can cause the DC-1500 fault pro-

tection circuitry to trip the machine off the line, if the

operator does not gouge in such a way to limit the cur-

rents.

General Set-Up Procedures When Using DC-1500 and

Lincoln Automatic Head NA-3

(Read the following and refer also to the chart on page 9.)

1. NA-3 — The NA-3 should be set for the mode being

used on the power source. If using either of the CV

modes, the NA-3 VV board switch should be set for

CV. If the power source is used in the VV mode, then

the NA-3 VV board mode switch should be placed in

the VV position.

All NA-3’s when used with the DC-1500 are capable of

cold starting with the variable voltage board mode

switch in VV. Cold starting permits the wire to be

inches down to the work, automatically stop and au-

tomatically energize the flux hopper valve. All NA-3’s

made after September 1976, are capable of cold starting

on either CV or VV settings of the variable voltage board

switch.

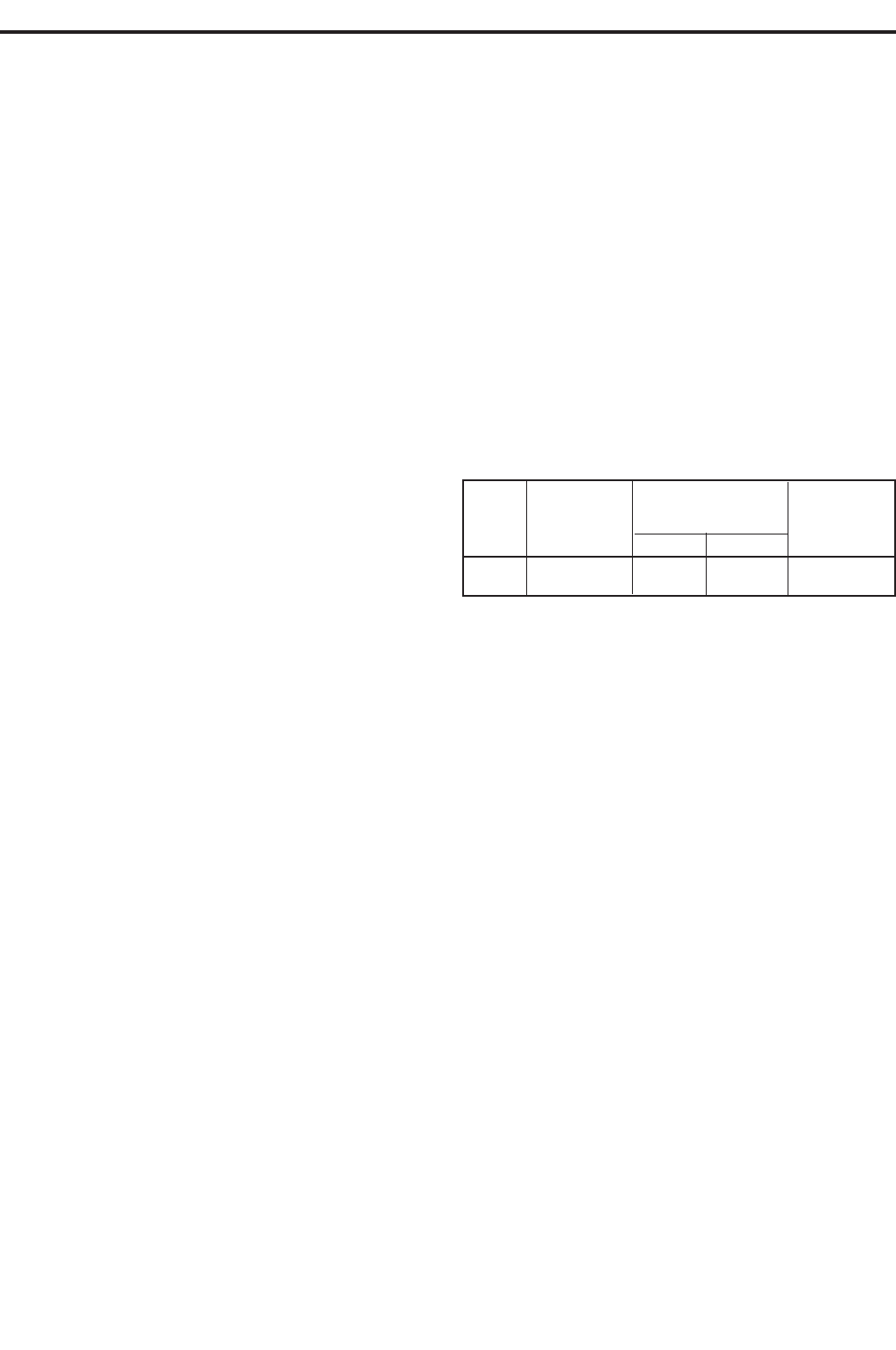

Combined Total

Electrode and

Electrode

Carbon Typical

Work Lead Length

and Work

Size Current Range (Min) (Max) Lead Size

1

/

2

600-1000 Amps 250’ 825’ 2 — 4/0

5

/

8

800-1200 Amps 375’ 925’ 3 — 4/0

-7-