%*+##+ &%

-%+S

#&+ &%%-%+ #+ &%

The welder should be located to provide an unrestrict-

ed flow of clean, cool air to the cooling air inlets and to

avoid restricting the cooling air outlets. Also, locate

the welder so that the engine exhaust fumes are prop-

erly vented to an outside area.

*+" %

VANTAGE® 300 machines cannot be stacked.

%#&&')+ &%

Engines are designed to run in the level condition

which is where the optimum performance is achieved.

The maximum angle of continuous operation is 20

degrees in all directions, 30 degrees Intermittent (less

than 10 minutes continuous) in all directions. If the

engine is to be operated at an angle, provisions must

be made for checking and maintaining the oil level at

the normal (FULL) oil capacity in the crankcase.

When operating the welder at an angle, the effective

fuel capacity will be slightly less than the amount

specified.

*+0'),+ &%*

&@>KCG3>;8;76B7DEA@@7>E:AG>6;@EF3>>

GE7ADE7DH;57F:;E7CG;B?7@F

A@AF3FF7?BFFAGE7F:;E7CG;B?7@FG@F;>KAG

:3H7F:ADAG9:>KD736F:77@9;@7?3@G835FGD7D\E

?3@G3>EGBB>;76I;F:KAGDI7>67D F;@5>G67E

;?BADF3@FE387FKBD753GF;A@E67F3;>767@9;@7

EF3DF;@9AB7D3F;@93@6?3;@F7@3@57;@EFDG5F;A@E

3@6B3DFE>;EFE

#+) *&"53@=;>>

RA@AFFAG5:7>75FD;53>>K>;H7B3DFEAD

7>75FDA67I;F:E=;@ADI7F5>AF:;@9

R @EG>3F7 KAGDE7>8 8DA? IAD= 3@6

9DAG@6

R>I3KEI73D6DK;@EG>3F;@99>AH7E

% %[/,*+[53@=;>>

R,E7;@AB7@I7>>H7@F;>3F763D73EAD

H7@F7J:3GEFAGFE;67

$&- %')+*[53@;@<GD7

RA@AFAB7D3F7I;F:6AADEAB7@AD

9G3D6EA88

R*FAB7@9;@7478AD7E7DH;5;@9

R"77B3I3K8DA??AH;@9B3DFE

*77 366;F;A@3> I3D@;@9;@8AD?3F;A@ 3F

8DA@FA8F:;EAB7D3FAD\E?3@G3>

.)% %

-)-&#+),+ &%-

The VRD feature provides additional safety in the CC-Stick

mode especially in an environment with a higher risk of

electric shock such as wet areas and hot humid sweaty

conditions.

The VRD reduces the OCV (Open Circuit Voltage) at the

welding output terminals while not welding to less than 13V

DC when the resistance of the output circuit is above 200Ω

(ohms).

The VRD requires that the welding cable connections be

kept in good electrical condition because poor connections

will contribute to poor starting. Having good electrical con-

nections also limits the possibility of other safety issues

such as heat-generated damage, burns and fires.

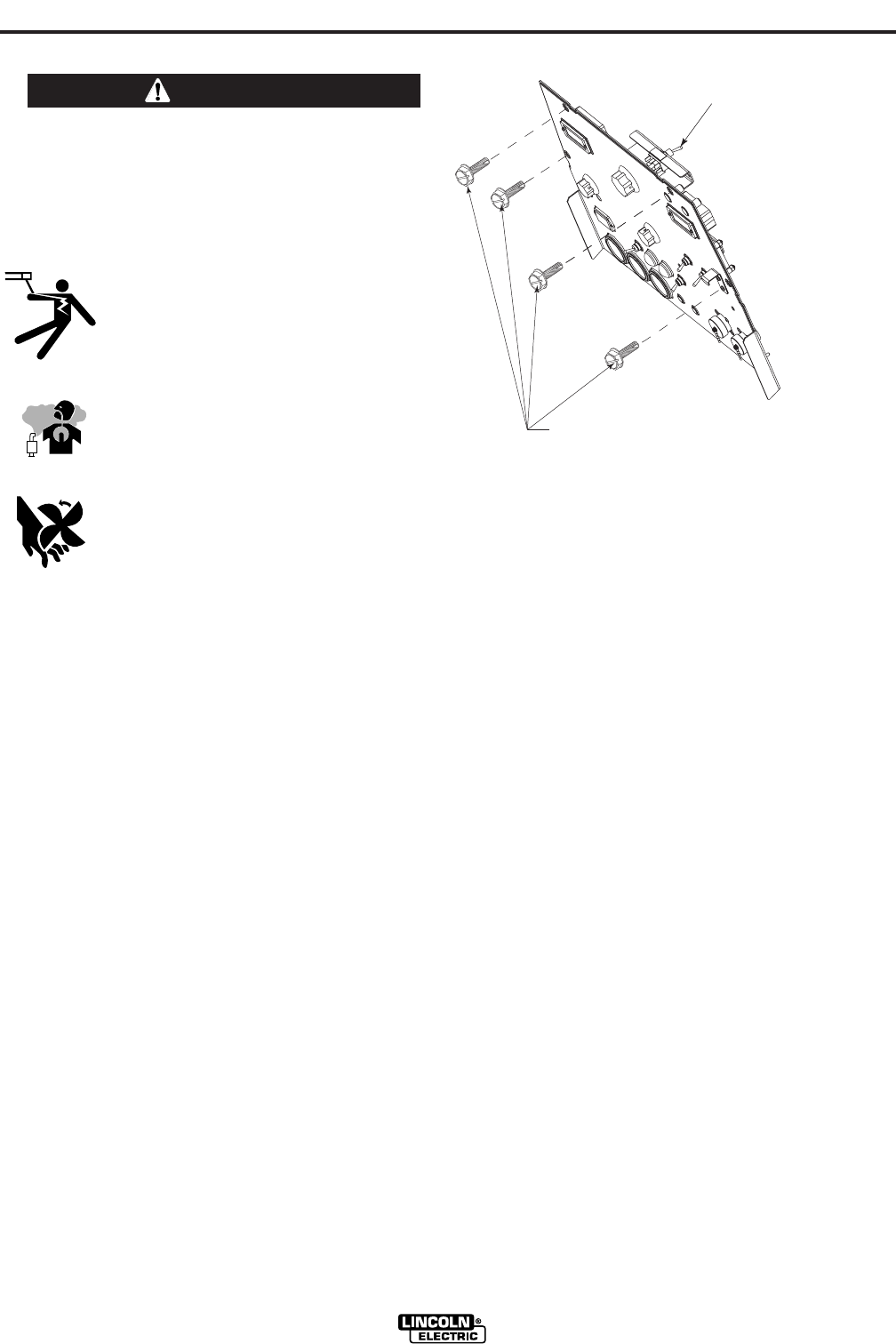

The machine is shipped with the VRD switch in the “Off”

position. To turn it “On” or “Off”.

• Turn the engine “Off”.

• Disconnect the negative battery cable.

• Lower the control panel by removing 4 front

panel screws.

(See Figure A.1)

• Place the VRD switch in the “On” or “Off” position.

(See Figure A.1)

With the VRD switch in the “On” position, the VRD lights

are enabled.

(VRD)-VOLTAGE REDUCTION DEVICE

SWITCH IS LOCATED IN THIS AREA.

REMOVE 4 FRONT PANEL

SCREWS TO ACCESS

(

VRD) SWITCH

(VRD)-VOLTAGE REDUCTION DEVICE

SWITCH IS LOCATED IN THIS AREA.

REMOVE 4 FRONT PANEL

SCREWS TO ACCESS

(

VRD) SWITCH

,)