B-2

OPERATION

B-2

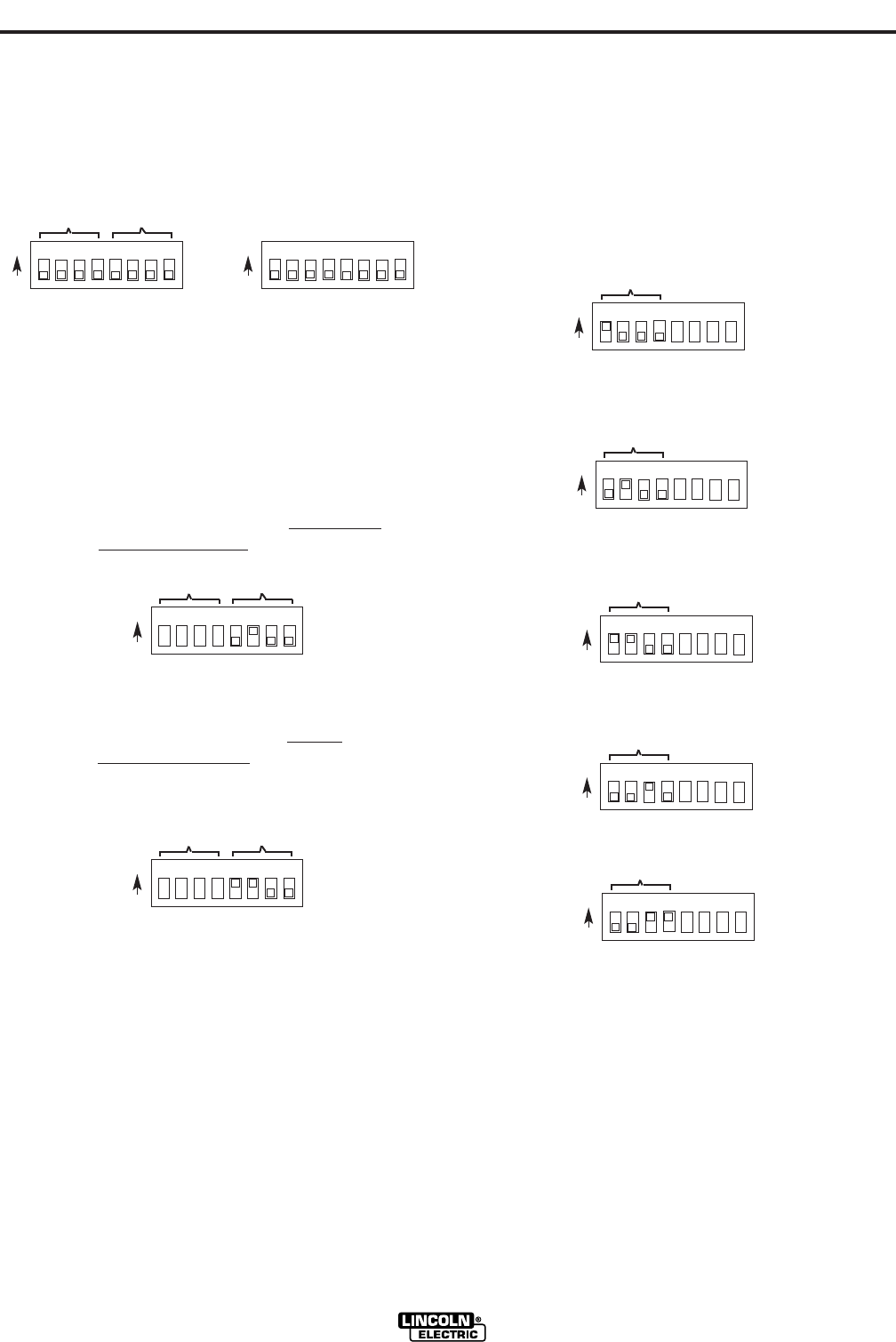

Setting the DIP Switches

The DIP switches are each labeled with an “ON”

arrow showing the on direction for each of the 8 indi-

vidual switches in each DIP switch (S1 and S2). The

functions of these switches are also labeled and set

as described below:

Wire Drive Head Selection

The LN-10 control is set up for proper presettable wire

feed speed by setting S1 DIP switches (5 to 8) as

appropriate per the following examples for the head

specification and 10 Series wire drive external gear

selection being used:

For K1559-5 (LN-10 Bench) with 35-500 IPM

(0.89-

12.7 m/m) Low Speed Ratio set S1 DIP Switch as

follows:

For K1559-5 (LN-10 Bench) with 50-750

IPM (1.25-

19.0 m/m) High Speed Ratio

set S1 DIP Switch as

follows: (initial factory setting)

LN-10

Welding Power Source Selection

The LN-10 Control is set up for proper presettable

weld voltage control by setting S1 DIP switches (1 to

4) as appropriate per the following information for the

welding power source being used:

CV-250/CV 300-I:

CV-300/CV 400-I:

CV-400/CV 500-I:

CV-655: (initial factory setting)

V350-PRO And V450-PRO:

Pwr Sources

S1

ON

S1

12345678

Pwr Sources

S1

ON

S1

12345678

Pwr Sources

S1

ON

S1

12345678

Pwr Sources

S1

ON

S1

12345678

Pwr Sources

S1

ON

S1

12345678

Pwr Sources

S1

ON

S1

12345678

M 4 S R + -

S2

ON

S2

12345678

Head

Pwr Sources

S1

ON

S1

12345678

Head

Pwr Sources

S1

ON

S1

12345678

Head