TROUBLESHOOTING

LN-10

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

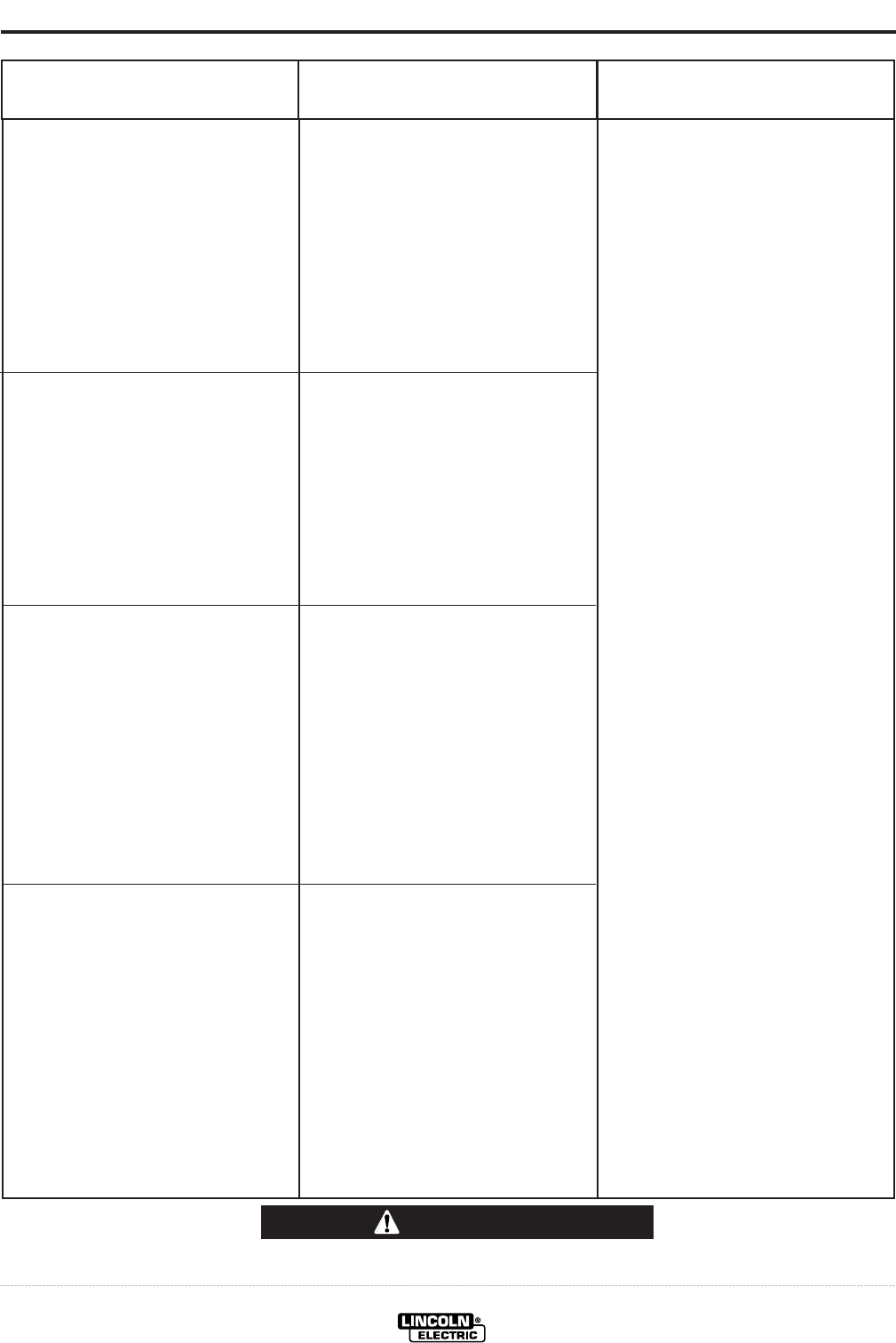

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Speed does not change when weld

current flows.

Voltmeter does not function proper-

ly. Welding may or may not vary

from normal procedure. Wire feeds

properly.

Cold feed forward or cold feed

reverse buttons on keypad do not

work, but motor control otherwise

functions properly.

Gas purge key does not operate

the gas solenoid, but gas flow does

occur while welding.

1. Run-in and weld speeds are set

to the same value.

2. Current sensing reed switch is not

operating properly.

3. The wiring from the control p.c.

board to the weld current sensing

reed switch is damaged.

4. Damaged control p.c. board.

1. The work sense lead (#21) or the

electrode sense lead (#67) may

have intermittent or poor connec-

tions.

2. Improper power source selection

on the control p.c. board.

3. Control p.c. board failure.

1. The connector from the control

p.c. board to the display p.c.

board or the connector from the

display p.c. board to the keypad

are loose or improperly inserted.

2. Damaged keypad

3. Damaged display p.c. board.

4. Damaged control p.c. board.

1. The connector from the control

p.c. board to the display p.c.

board or the connector from the

display p.c. board to the keypad

are loose or improperly inserted.

2. Damaged keypad

3. Damaged display p.c. board.

3. Damaged control p.c. board.

E-4E-4

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service Facility.