E-2

TROUBLESHOOTING & REPAIR

E-2

LN-7 & LN-7 GMA

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Authorized

Field Service Facility.

CAUTION

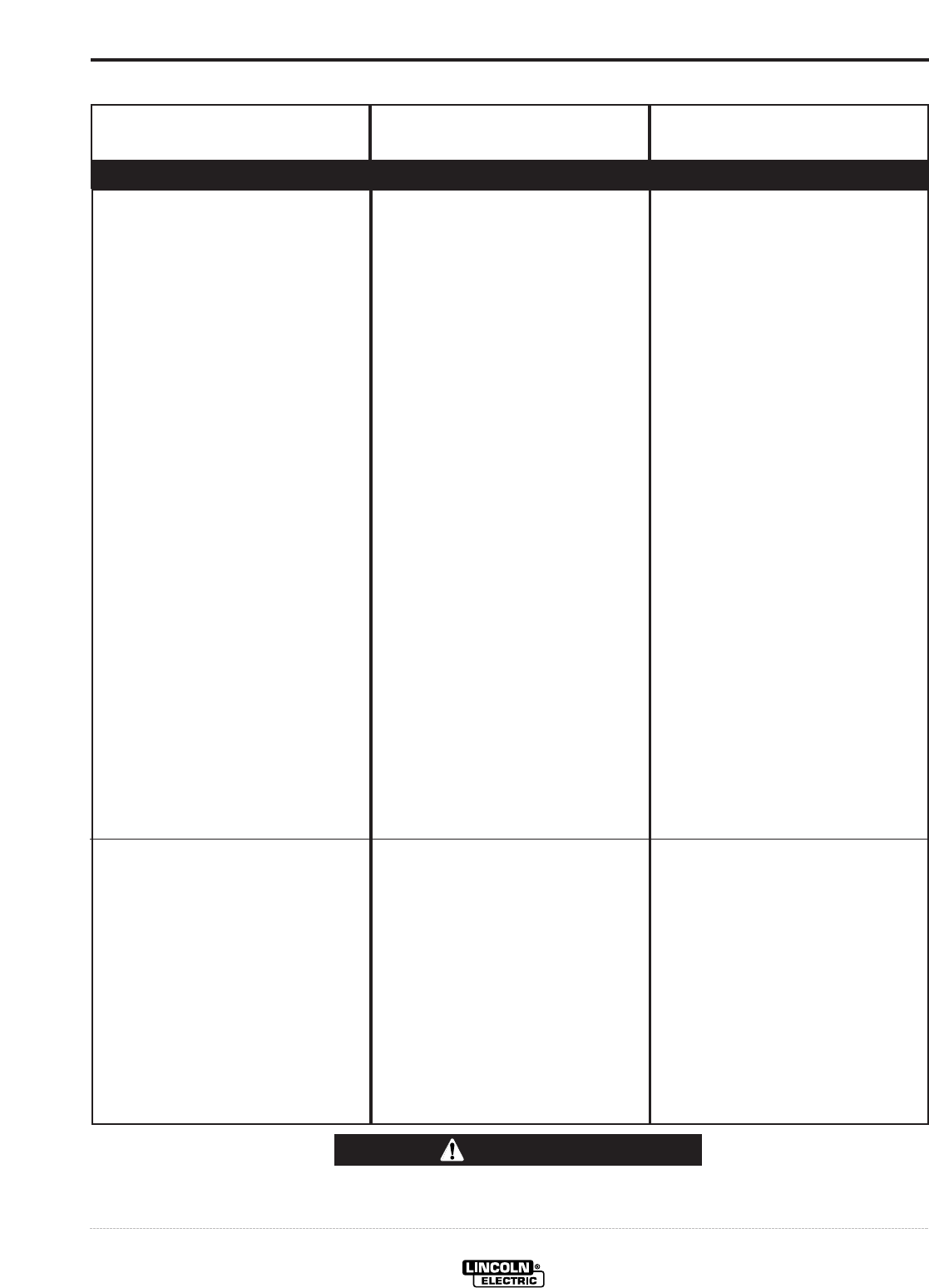

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Rough wire feeding or wire not feed-

ing but drive rolls are turning.

Variable or hunting arc.

1. Gun cable kinked and/or twisted.

2. Wire jammed in gun and cable.

3. Incorrect size or installation of

drive rolls and guide tubes.

4. Drive roll loose.

5. Gun cable dirty.

6. Worn drive rolls.

7. Electrode rusty and/or dirty.

8. Worn nozzle or cable liner.

9. Partially flashed or melted contact

tip.

10. Incorrect idle roll pressure.

11. Wire reel brake tension set too

high.

1. Worn and/or melted contact tip.

2. Worn work cable or poor work

connection.

3. Loose electrode connections.

4. Wrong polarity.

1. Inspect gun cable and replace if

necessary.

2. Remove wire from gun and cable -

feed in new wire. Note any

obstructions in gun and cable.

Replace gun and cable if neces-

sary.

3. Refer to Operation Section for

proper installation of drive rolls

and guide tubes.

4. Remove, clean, install and tighten.

5. Clean cable or replace liner.

6. Replace.

7. Replace.

8. Replace.

9. Replace contact tip.

10. Set idle roll pressure see

Operation Section of manual.

11. Tension should be just high

enough to prevent overrun.

1. Replace tip - remove any spatter

on end of tip

2. Inspect - repair or replace as nec-

essary.

3 Be sure electrode lead is tight, gun

cable tight in wire feeder contact

block, gun nozzle and gun tip tight.

4. Check connection at output studs

for polarity required by welding

process.