E-3

TROUBLESHOOTING & REPAIR

E-3

LN-7 & LN-7 GMA

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Authorized

Field Service Facility.

CAUTION

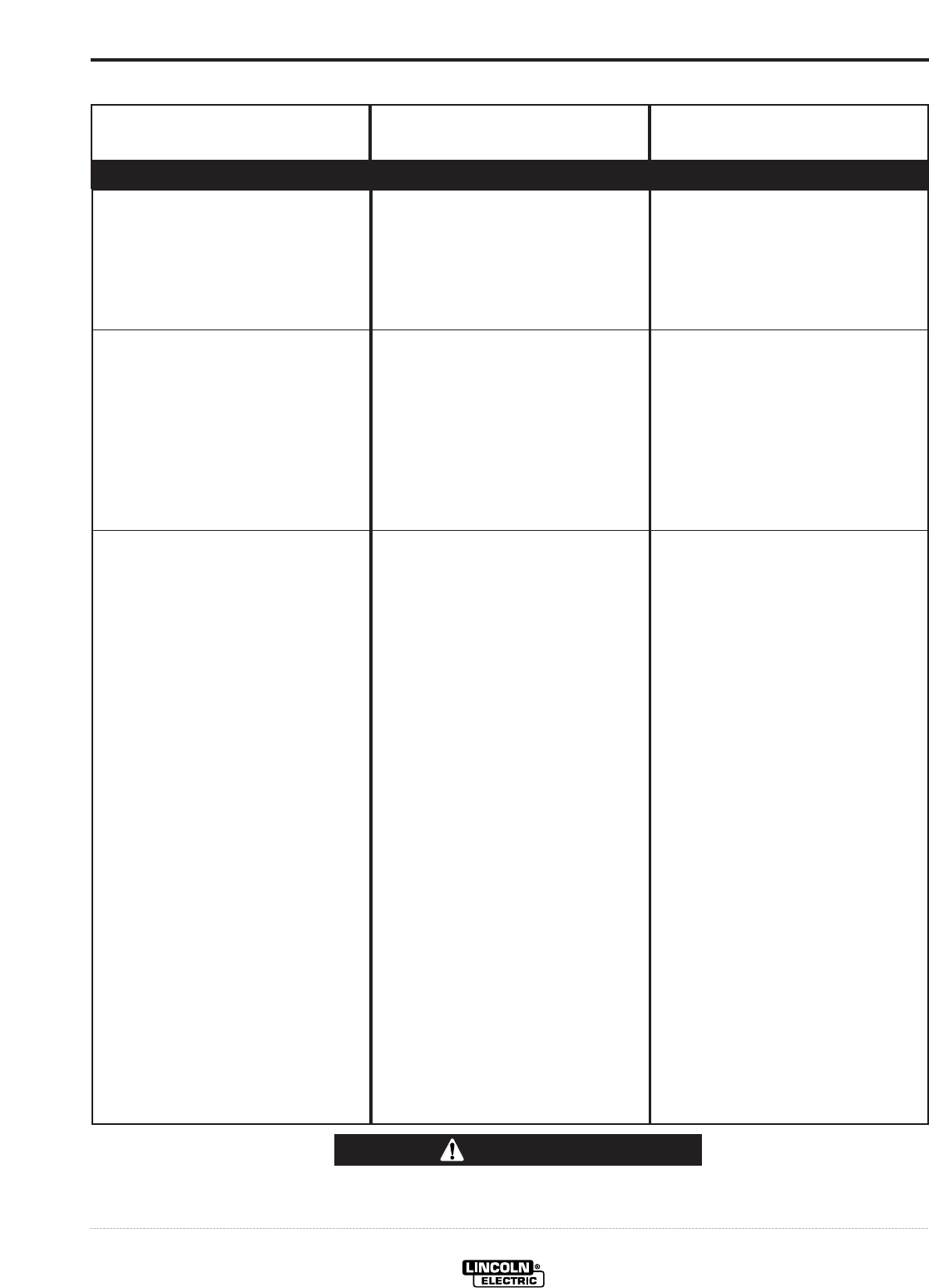

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Weld porosity, narrow and ropey

bead, or electrode stubbing into

plate when welding.

LN-7 circuit breaker trips while weld-

ing.

LN-7 or power source electrical

problems such as:

• Power source fuse blowing.

• LN-7 circuit breaker tripping.

• No control of wire feed motor.

• Wire feed motor not running.

• Auxiliary equipment connected

to 32A and 7 not working.

• Power source contactor not

working but LN-7 feeds wire.

1. Contaminated weld joint or

improper procedures.

2. Lack of shielding gas.

1. See problem 1.

2. High ambient temperature (caus-

ing circuit breaker to trip).

3. Electrical problems in power

source or LN-7

1. Loose connections or broken lead.

2. Grounding lead protector tripped.

3. Electrical component has failed.

4. Contactor circuit fuse on motor

control P.C. board blown.

1. Clean welded joint. Check that

controls are set correctly for pro-

cedure.

2. Obtain proper gas flow.

1. Correct problems.

2. Provide better ventilation for LN-7.

Make sure ventilation louvers and

clean and un-obstructed.

3. See problem 5.

1. Turn power source and LN-7 off

and check leads and connections.

2. Push reset button.

3. Replace blown fuses or reset cir-

cuit breaker and try to weld. If

trouble reoccurs, contact your

local authorized field service shop.

4. Correct problem and replace fuse

(2A-250V)