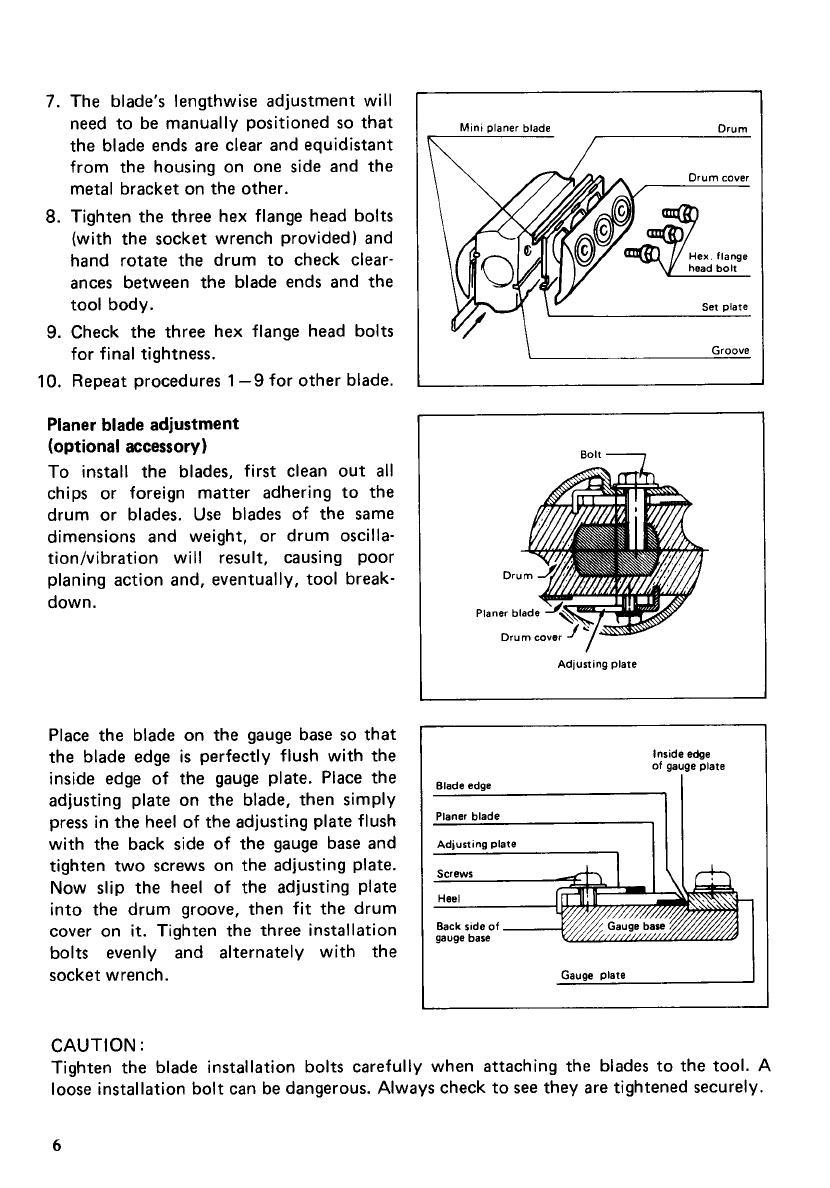

7.

The blade's lengthwise adjustment will

need to be manually positioned

so

that

the blade ends are clear and equidistant

from the housing on one side and the

metal bracket on the other.

8.

Tighten the three hex flange head bolts

(with the socket wrench provided) and

hand rotate the drum to check clear-

ances between the blade ends and the

tool body.

9.

Check the three hex flange head bolts

for final tightness.

IO.

Repeat procedures

1-9

for other blade.

Planer blade adjustment

(optional accessory)

To

install the blades, first clean out

all

chips or foreign matter adhering to the

drum or blades. Use blades of the same

dimensions and weight, or drum oscilla-

tion/vibration will result, causing poor

planing action and, eventually, tool break-

down.

Place the blade on the gauge base

so

that

the t.ade edge

is

perfectly flush with the

inside edge of the gauge plate. Place the

adjusting plate on the blade, then simply

press in the heel of the adjusting plate flush

with the back side of the gauge base and

tighten two screws on the adjusting plate.

Now slip the heel of the adjusting plate

into the drum groove, then fit the drum

cover on

it.

Tighten the three installation

bolts evenly and alternately with the

socket wrench.

I

Mini

planer blade Drum

s-

\

Groove

Plar

ier

blade

yq

Drum

cover

'

Bolt

Drum

-

Adjusting plate

I

Inside edge

of

gauge plate

Blade edge

Planer blade

Adjusting plate

Back side

of

--

gauge base

Gauge plate

CAUTION

:

Tighten the blade installation bolts carefully when attaching the blades to the tool. A

loose installation bolt can be dangerous. Always check to

see

they are tightened securely.

6