1.5

MIG/MAG 140/160

Care and Maintenance

The unit is nearly maintenance-free.

B

Danger – Voltage!

Disconnect from power before servicing!

x Check feed roller, pressure roller and wire lead-

in nozzle at regular intervals for dirt build-up,

clean if necessary.

x At appropriate intervals the complete torch

including torch leads should be cleaned, as

rubbed-off parts and dust build-up inside.

x The torch's contact tip is a wearing part. If its ori-

fice has enlarged the contact tip must be

replaced.

x On the inside of the plug-on gas shroud spatters

build up. These have to be removed when nec

-

essary. An anti-spatter spray eases this job and

keeps spatters from sticking to the shroud.

x Replace damaged cables without delay.

Trouble Shooting

Mechanical faults are mostly indicated by an irregu-

lar or completely blocked wire feed. Electrical faults

cause a malfunction of the unit, in part or complete.

B

Danger - Voltage!

Electrical fault finding must be left to a quali-

fied electrician.

Further fault finding can proceed according to the

wiring diagram supplied.

Fault find should first start with the unit de-ener-

gized, and in the following order:

1. Check of the power supply cable connection

and all other connections on switches, trans-

former and choke, as well as all plug-and-socket

connections and soldered connections for tight-

ness.

2. Check of fuse for continuity and contact.

3. Visual check for possible shorts or overloads of

windings (discoloring).

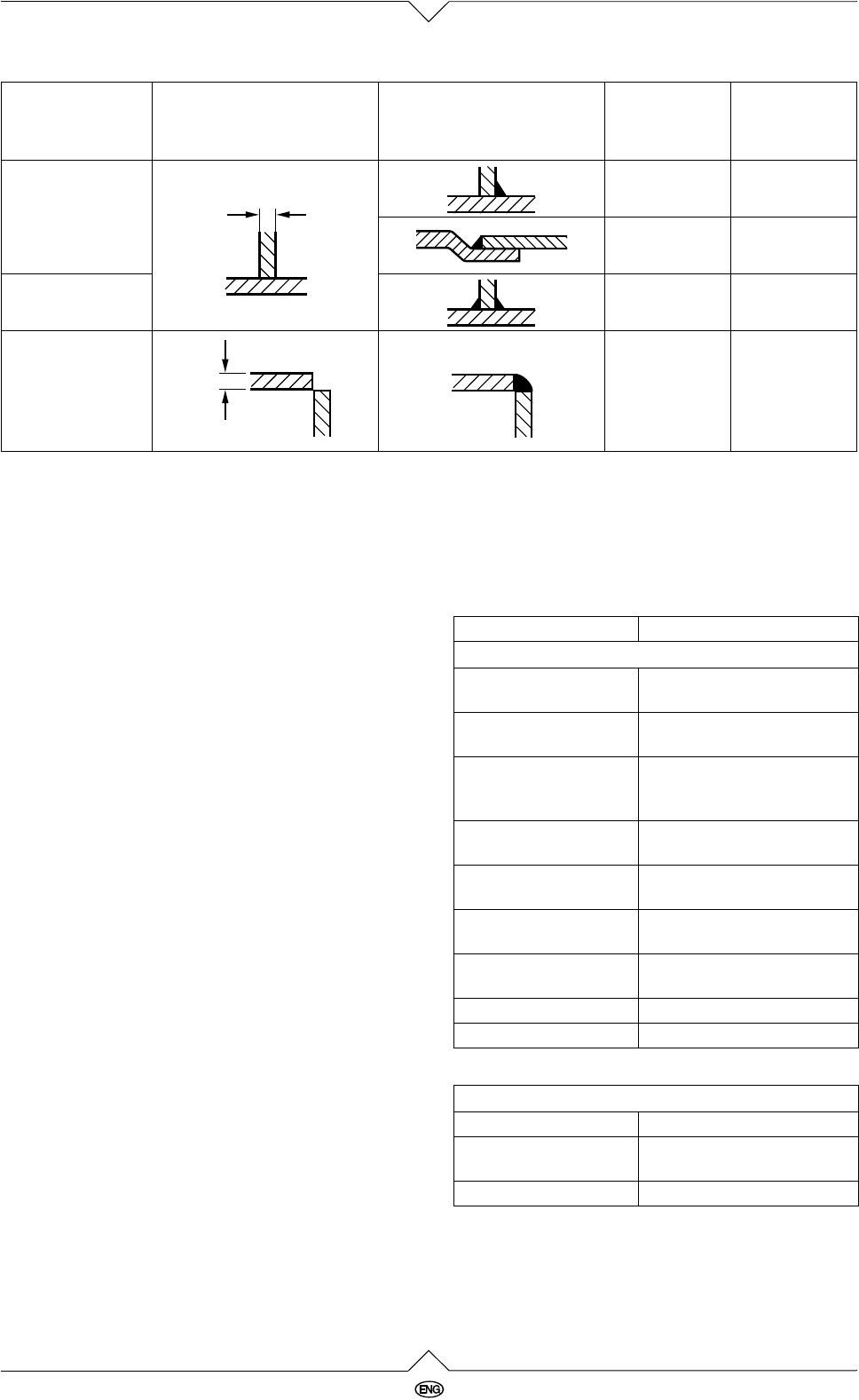

K-joint

> 0,6 –

0,6 – 1,5 –

Double-K-joint

> 0,6 –

Cornerjoint

> 1 –

Form of joint Execution

Platethick-

ness

s (mm)

Gapwidth

b (mm)

s

s

Fault, Likely causes Remedy

• Noisy or unstable arc?

Incorrect welding volt-

age

Correct with welding step

switch

Too much/too little wire

feed

Correct with wire feed pot

Earth clamp loose or

high contact resistance

(rust, paint)

Ensure good contact

between earth clamp and

workpiece

Contact tip worn or

incorrect diameter

Replace

Incorrect gas flow rate

setting

Correct

Workpiece not clean in

seam area

Remove paint, rust, grease

etc.

Power unit faulty Have machine checked by

service centre

Spiral liner dirty Clean or replace

Wire feed faulty See below

• Excessive spattering

Wire feed rate too high Correct with wire feed pot

Welding voltage too

high

Correct with welding step

switch

Workpiece not clean Clean