29

ENGLISH

9.5 Machine Cleaning

Remove chips and saw dust with brush

or vacuum from:

− setting devices;

− the operating elements;

− motor vent slots;

− space below table insert.

9.6 Machine storage

A

Danger!

• Store the saw in such way that it

cannot be used or tampered with

by unauthorised persons.

• Make sure that nobody can get

injured by the stored machine.

A

Caution!

• Do not store saw unprotected

outdoors or in damp environ-

ment.

• Observe the permissible ambient

conditions (see "Technical Speci-

fications").

9.7 Maintenance

Prior to every use

• Remove saw dust and chips with

vacuum or brush.

• Check power cable and power cable

plug for damage; if necessary, have

damaged parts replaced by a quali-

fied electrician.

• Check all moving parts to see that

they can move freely across their

whole range of travel.

Periodically, depending on operating

conditions

• Check all screwed joints, retighten if

necessary.

• Check pull-back springs of the saw-

head (the sawhead must return by

spring power to its upper starting

position), replace if necessary.

− For long stock use suitable supports

on both sides of the saw.

− When performing bevel cuts, hold

the workpiece on the right side of

the saw blade.

− Use auxiliary fence when sawing

small cut-offs (this may be a suitable

board, fastened with four screws to

the fence).

− When cutting warped stock, place

the convex side of the bow against

the fence.

− Do not cut stock standing on edge;

always place it flat on the rotating

table.

− Keep the supporting surfaces clean

– in particular, remove resin residue

with a suitable cleaning and mainte-

nance spray.

For special tasks the following accesso-

ries are available at your specialised

dealer – see back cover for illustrations:

A Multi-Suction Adapter

To connect different dust collection

attachments.

B Table Extension

Required when cutting long stock;

folds up to save space.

C Work Stand

For a secure machine stand and

optimal working height;

folding, ideal for mobile use.

D TCT saw blade 210 x 2.0 / 1.4 x 30

20 alternate bevel teeth

for wood and non-laminated parti-

cle board.

E TCT saw blade 210 x 2.4 / 1.8 x 30

40 alternate bevel teeth

For wood and panels.

A

Danger!

Repairs to electric tools must

be carried out by qualified electri-

cians only!

Electric tools in need of repair can be

sent to the Service Centre of your coun-

try. Refer to the spare parts list for the

address.

Please attach a description of the fault to

the electric tool.

The machine's packing can be 100%

recycled.

Worn out power tools and accessories

contain considerable amounts of valua-

ble raw and rubber materials, which can

be recycled.

These instructions are printed on paper

produced with elemental chlorine free

bleaching process.

This section describes problems and

malfunctions which you should be able

to resolve yourself. If the measures

described here do not solve your prob-

lem, see under "Repairs".

A

Danger!

Many accidents happen partic-

ularly in connection with problems

and faults. Therefore please note:

• Always unplug before servicing.

• Check to see that all safety

devices are operational after each

fault service.

Motor does not run

No mains voltage

• Check cables, plug, outlet and

mains fuse.

No crosscut function

Transport locking pin engaged:

• Pull transport locking pin out.

Safety lock engaged:

• Actuate the safety lock.

Only little sawing performance

Saw blade blunt (possibly tempering

marks on blade body):

Saw blade not suitable for material being

cut (see chapter "Technical Specifica-

tions");

Saw blade warped:

• Replace saw blade (see chapter

"Maintenance").

Saw vibrates heavily

Saw blade warped:

• Replace saw blade (see chapter

"Maintenance").

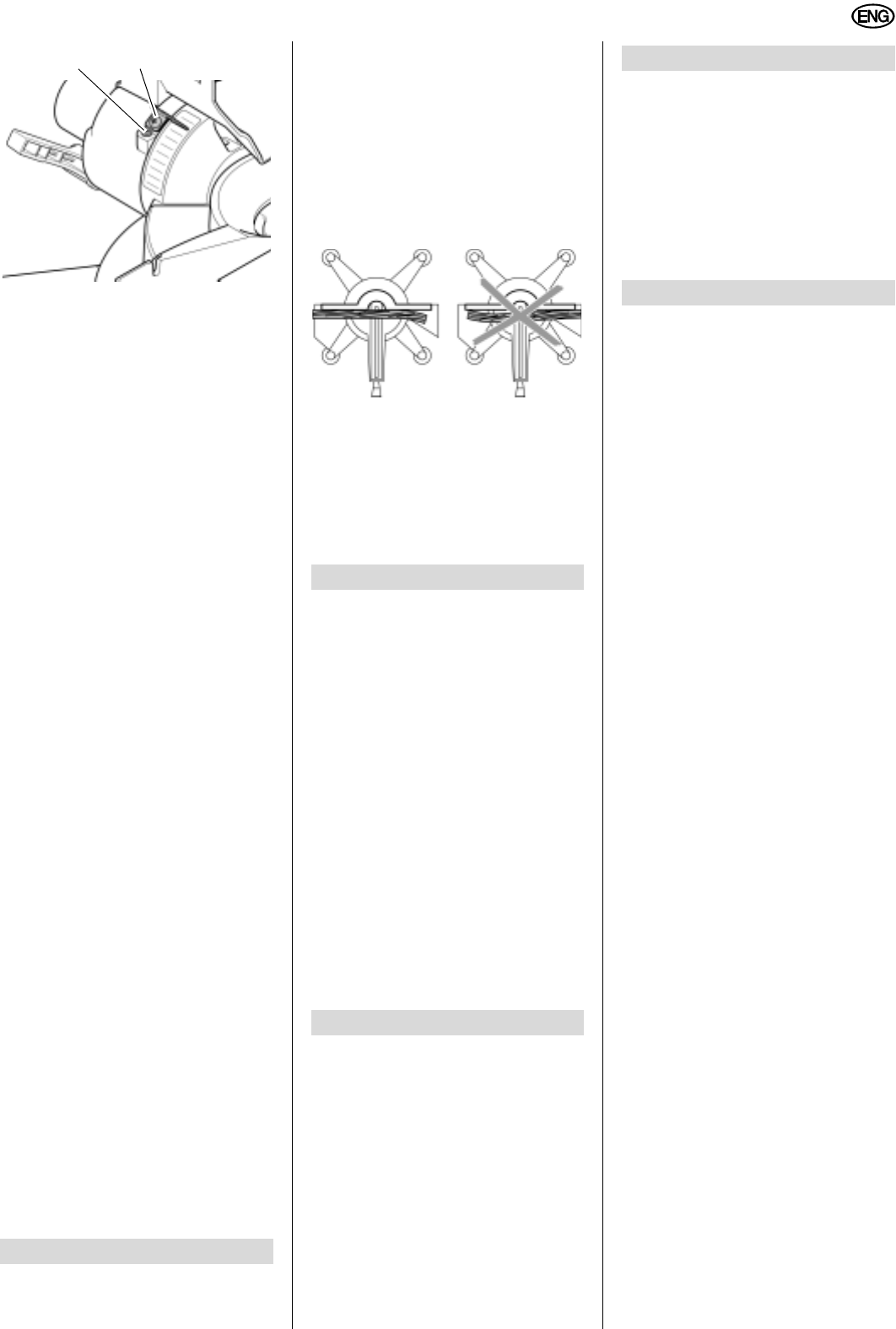

Saw blade incorrectly mounted:

• Mount saw blade correctly (see

chapter "Maintenance").

Stiffness of rotating table

Saw dust build-up under rotating table:

• Remove saw dust.

10. Tips and Tricks

9493

11. Available Accessories

12. Repairs

13. Environmental Protection

14. Troubleshooting Guide