OM-210 540 Page 26

Table 4-2. Robot Abbreviations

Manufacturer

Robot Abbreviation

ABB ABB

Fanuc FANU

Daihen DAHN

Kawasaki KAWA

Kuka KUKA

Comau COMU

Hitachi HCHI

Nachi NCHI

Panasonic PANA

Motorman MOTO

Robot Adapter DTEC

Detect Disabled OFF

None Robt DTEC

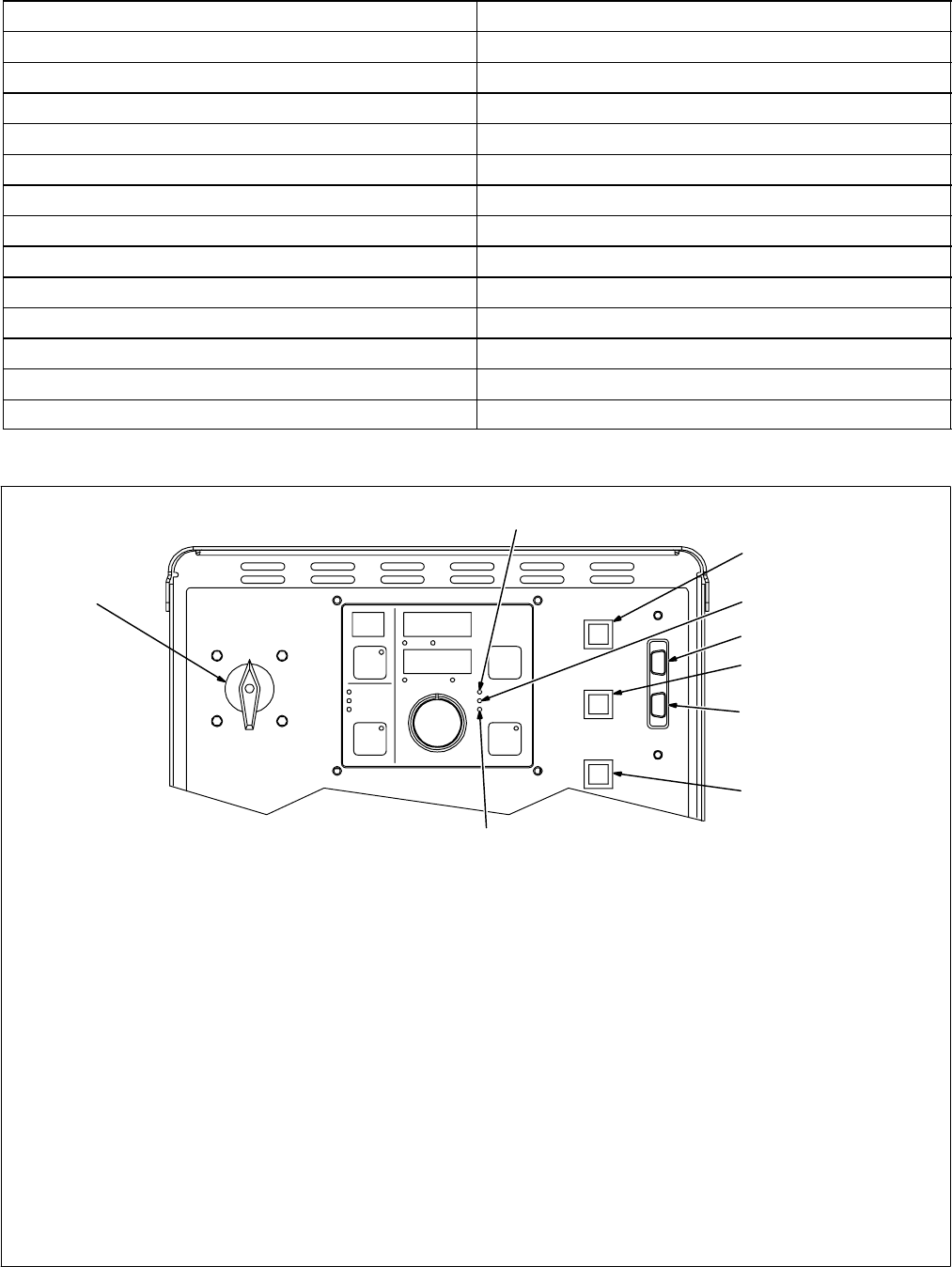

4-4. Front Panel Switches

1

2

3

4

Ref. 803 246-B

1 Power Switch

Turns unit On or Off.

The power-up sequence may last up to 30

seconds before the unit is ready to weld.

During power-up, the front panel will display

messages indicating the status of the unit. The

first message is:

NET

WAIT

NET WAIT is an abbreviation for ”network

updating” and means the internal control

network is powering up. The next message is

XXXX (Robot Type)

XXXX identifies the robot adapter being used

as identified by the unit (see Table 4-2 for a list

of robot adapters that could be displayed). To

ensure proper operation of the system, verify

the robot displayed corresponds to the actual

robot being used. The final message is

AUTO

450

AUTO 450 indicates the software being

loaded.

2 Contactor LED

Contactor LED illuminates when weld output is

energized.

3 Purge Push Button

Press button to purge gas line.

4 Gas LED

Gas LED illuminates when Purge push button

is pressed.

5 Jog Push Button

Press button to jog wire.

6 Wirefeed LED

Wirefeed LED illuminates when wire feeds or

retracts.

7 Retract Push Button

Press button to retract wire. Wirefeed LED

illuminates when Retract push button is

pressed.

Auto-Threading feature is activated by

pressing the Jog and Retract buttons

simultaneously. Pressing the Jog, Purge, or

trigger switch will turn off the Auto-Threading

feature.

8 PDA Port

9 PC Port

6

7

5

8

9