OM-481 Page 25

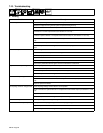

7-5. Adjusting Engine Speed

Y Stop engine.

Engine speeds have been factory

set and should not require adjust-

ment. After tuning engine, check

engine speeds with a tachometer.

See table for proper no load

speeds. If necessary, adjust

speeds as follows:

1 Speed Adjustment Screw

2 Locknut

Loosen nut. Start engine.

Turn screw until engine runs at

weld/power speed. Tighten locknut.

Y Stop engine.

Close side door.

Ref. ST-134 730-C / Ref. SD-131 784-A

1

2

Tools Needed:

9/16, 7/8 in

Engine Speed

Weld/Power

RPM

1850

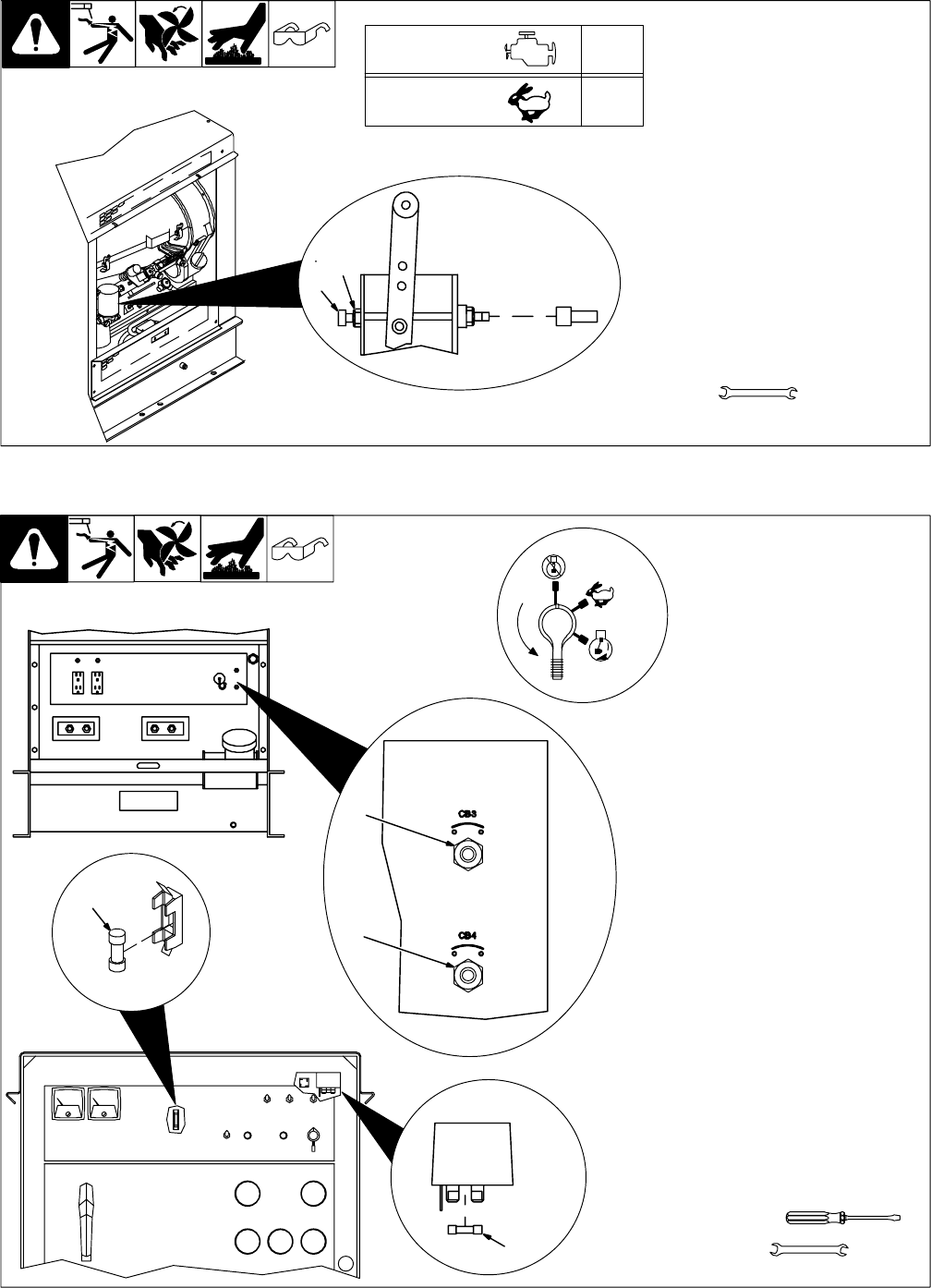

7-6. Overload Protection

Ref. 184 780 / Ref. ST-174 733 / ST-156 468

Y Stop engine.

. When a fuse or circuit breaker

opens, it usually indicates a

more serious problem exists.

Contact a Factory Authorized

Service Agent.

1 Circuit Breaker CB3

CB3 protects the 115 volts ac out-

put to Remote 14 receptacle RC3 or

terminal strip 3T. If CB3 opens, the

115 volts ac output stops.

2 Circuit Breaker CB4

CB4 protects the 24 volts ac output

to Remote 14 receptacle RC3 or

terminal strip 3T. If CB4 opens, the

24 volts ac stops.

Press button to reset breaker.

3 Fuse F (See Parts List)

4 Fuse F6 (See Parts List)

Remove screw to open upper front

panel access door.

Fuse F protects the magnetic shut-

down switch MS1 from damage due

to overload. If F opens, the engine

stops. Do not run engine until

problem is corrected.

Check fuse, and replace if open.

Fuse F6 protects the excitation cir-

cuit from damage due to overload.

If F6 opens, there will be low/no

weld and generator power output.

Check fuse, and replace if open.

Tools Needed:

3/8, 1/2 in

1

2

OFF

START

RUN

3

4