OM-2252 Page 20

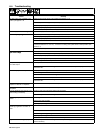

4-12. Electrical Service Guide

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda-

tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

50/60 Hertz Models

Input Voltage 230 380 400 440 460 575

Input Amperes At Rated Output 57 34 33 30 29 23

Max Recommended Standard Fuse Rating In Amperes

1

Time-Delay

2

70 40 40 35 35 25

Normal Operating 3 90 50 50 45 40 35

Min Input Conductor Size In AWG

4

6 8 8 10 10 10

Max Recommended Input Conductor Length In Feet (Meters) 145 (44) 256 (78) 284 (86) 226 (69) 243 (74) 380 (116)

Min Grounding Conductor Size In AWG

4

8 10 10 10 10 10

Reference: 2005 National Electrical Code (NEC)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose − no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

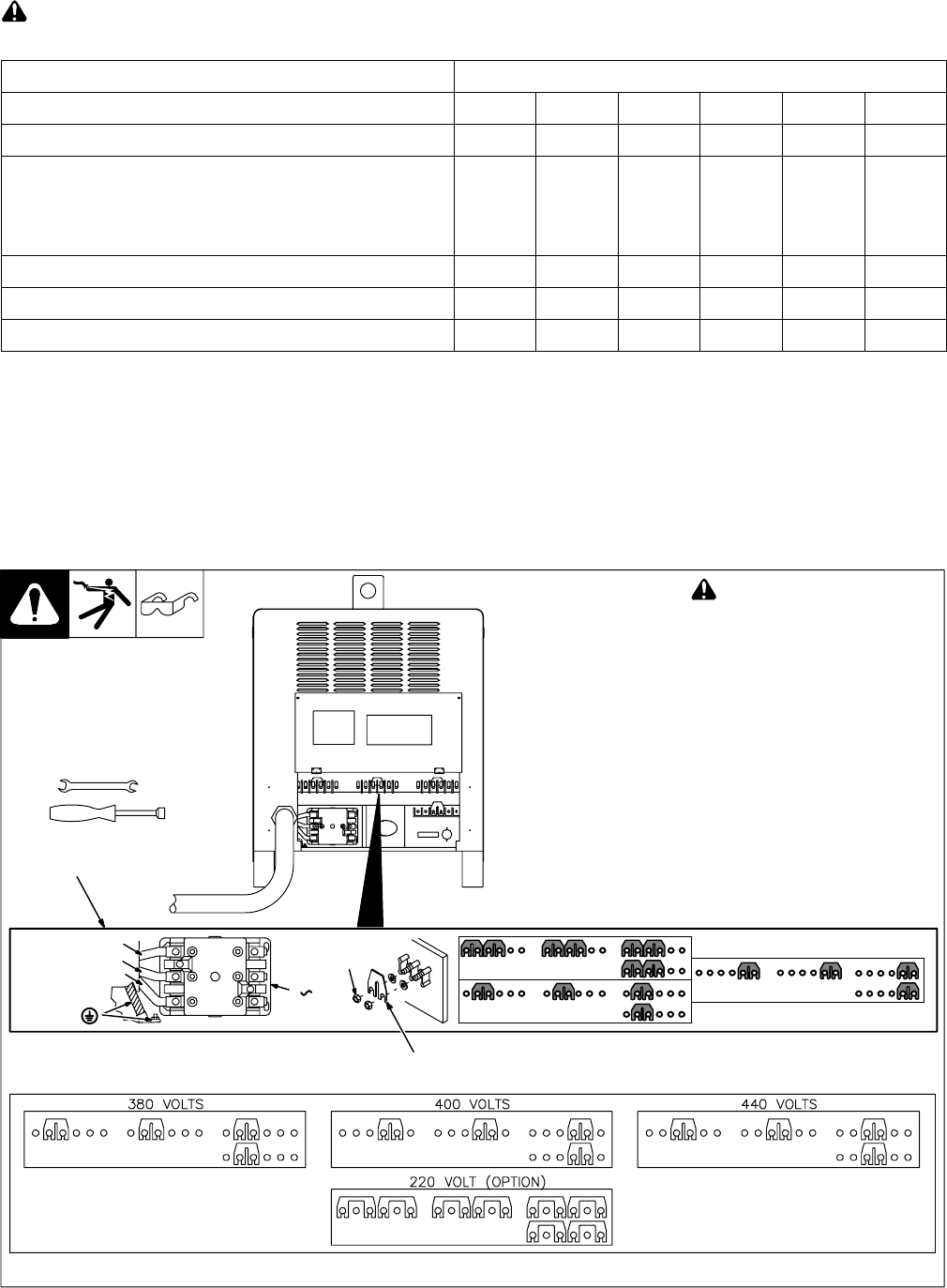

4-13. Placing Jumper Links

Ref. 800 103-A

! Disconnect and lockout/tag-

out input power before

installing or moving jumper

links.

Check input voltage available at

site.

1 Jumper Link Label

Check label.

2 Jumper Links

Move jumper links to match input

voltage.

Close access door, or go on to

Section 4-14.

Tools Needed:

1

3/8 in

3/8 in

L1 (U)

S−174 973−B

GND/ PE

3

Connect

GND/PE

Conductor

First.

I nput

Con t actor

L2 (V)

L3 (W)

230 VOLTS

460 VOLTS

575 VOLTS

Do not

overtighten

jumperlinknuts.

2