OM-2252 Page 22

SECTION 5 − OPERATION

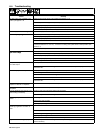

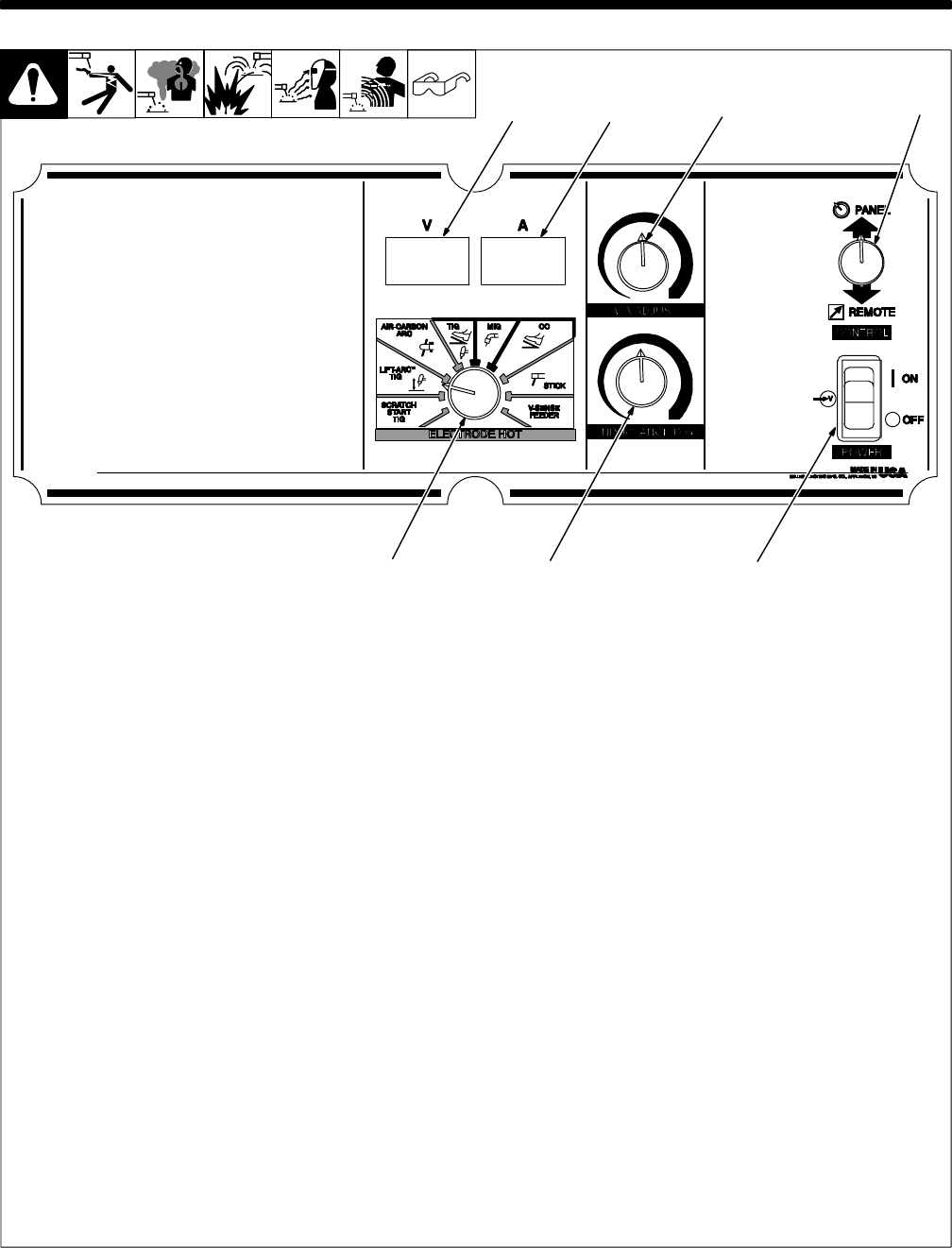

5-1. Controls

229 448-A

1

2

3

6

7

4

5

1 Power Switch

. This unit is equipped with a fan motor that

is thermostatically controlled and only

runs when cooling is needed.

2 Voltmeter (see Section 5-2)

3 Ammeter (see Section 5-2)

4 Mode Switch

Use Mode switch to determine both process

and output On/Off control. Orange areas

highlight “contactor on” positions.

5 Panel/Remote Control Switch

For front panel control, place switch in Panel

position and use the V/A Adjust control to set

amperage or voltage, depending on Mode

switch selection.

For remote control, make connections to Re-

mote 14 receptacle (see Section 4-11), and

place switch in Remote position. In TIG

modes, output available through the remote

control is a percent of the V/A Adjust control

setting. Value selected on V/A Adjust control

is maximum output available through the re-

mote control. In the MIG, CC, and V-Sense

feeder modes, a remote control provides full

range of unit output regardless of V/A Adjust

control setting. A remote control is not func-

tional in Air-Carbon Arc or Stick modes. If

connection to Remote 14 receptacle is re-

moved and Panel/Remote control switch re-

mains in Remote position, output is controlled

with the V/A Adjust control.

6 V/A (Voltage/Amperage) Adjust Control

With Mode switch in any Stick or TIG position,

use control to adjust amperage from 5 to 500

amps. With Mode switch in a V-Sense Feeder

or MIG position, use control to adjust voltage

from 10 to 38 volts.

7 Inductance/Dig Control

Control adjusts Dig when a Stick or CC mode

is selected on mode switch. When set to-

wards minimum, short-circuit amperage at

low arc voltage is the same as normal welding

amperage. When set to max, control in-

creases short-circuit amperage at low arc

voltage. This allows the operator to use a

very short arc length without sticking the

electrode. As control is adjusted, the amount

of Dig selected is displayed on the amps me-

ter as a percentage (0 to 100%) of full range,

and dig is displayed on the volts meter.

When Air-Carbon Arc mode is selected, Dig

is internally set to max.

Control adjusts inductance when MIG or V-

Sense Feeder position is selected on mode

switch. Inductance determines the “wetness”

of the weld puddle. As setting is increased to-

wards maximum, “wetness” (puddle fluidity)

increases. As control is adjusted, the amount

of inductance selected is displayed on the

amps meter as a percentage (0 to 100%) of

full range, and ind is displayed on the volts

meter.

This control is not functional when one of the

TIG modes is selected.

Change control setting to best suite

application.