SECTION 4 MAINTENANCE AND REPAIR

OM-179 078 4-4

TROUBLE INDICATION

REPAIR STEPS

Incorrect wire feed speed. Check input signal (TP15 on Controller/Driver circuit board). Replace

speed pot or circuit board if necessary.

Verify that thumbscrew is fully seated. Exception: Back off one full turn

when using .020 in diameter wire.

Verify that correct drive rolls for wire diameter are installed (see Table

1.1).

Check roller surface; if excessively worn, slip of urethane wheels and

replace.

Motor turns but wire does not Verify that drive unit is connected to control.

feed.

Verify that all plugs are installed in the circuit board.

Check motor and cable continuity. It should be about 1.5 ohms from

pin A, D, E, and C referenced to pin B on motor connector. Repair or

replace if necessary.

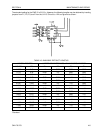

Check motor current (speed less than 10 ipm = 80 to 110 mV between

TP7 and TP8. See Figure 4.2) Replace circuit board if necessary.

Loosen feed tension adjustment knob completely. Verify wire runs

smoothly off wire reel and through guides and conduit.

Verify thumbscrew is properly adjusted. Exception: Back off one full

turn when using .020 in diameter wire.

Verify correct drive rolls for wire diameter (see Table 1.1).

Check roller surface; if excessively worn, slip off urethane wheels and

replace.

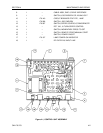

TABLE 4.2 PARTS LIST FOR DRIVE ASSEMBLY

ITEM QTY PART NMBR DESCRIPTION

1 1 179 168 BOGIE ASSEMBLY, DWF–3

2 1 179 169 DRIVE MOTOR ASSEMBLY, DWF–3

31 – COVER ASSEMBLY, DRIVE DWF–3

4 2 179 170 URETHANE ROLLER ASSEMBLY

51 – HOUSING, WIRE FEEDER

61 – RETAINER, DRIVE GEAR

7 2 179 171 BUSHING, GEAR SHAFT

8 2 179 172 SHAFT, BOGIE

9 1 179 173 GUIDE, WIRE – EXIT

10 1 179 174 GUIDE, WIRE – INLET

11 1 179 175 KNOB, SCREW

12 1 – CLAMP, BACKSHELL

13 1 – CONNECTOR, CIRCULAR STR PLUG

14 A/R – TUBING SHRINK, BLACK

15 1 179 176 SPRING COMPRESSION

16 2 – STRAIN RELIEF – PLASTIC

17 A/R – TUBING SHRINK – BLACK