OM-530 Page 11

AJ

B

K

I

C

L

NH

D

M

G

E

F

Ref. S-0004-A

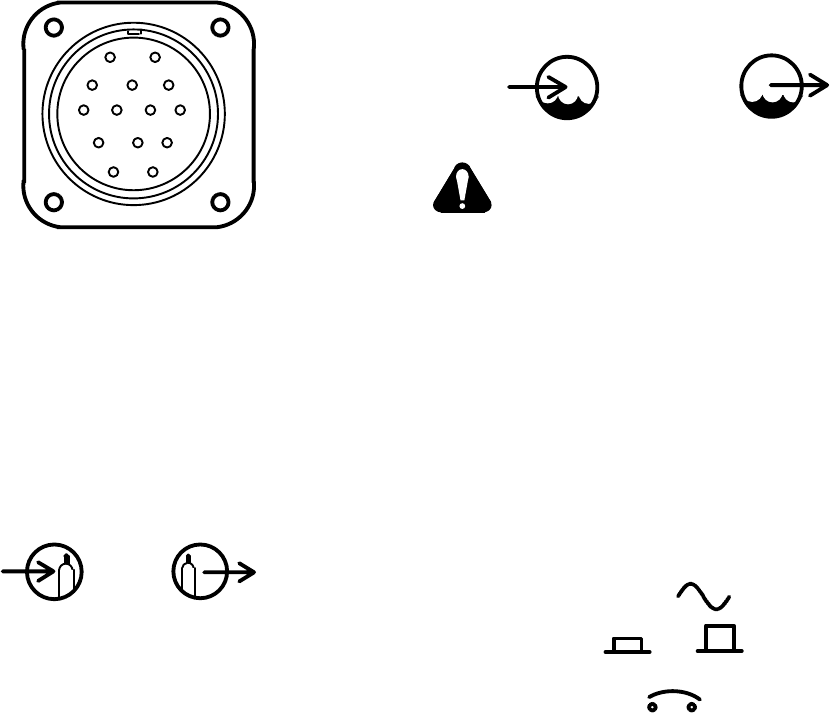

Figure 3-4. Front View Of REMOTE 14 Receptacle

With Socket Locations

3-11. GAS CONNECTIONS (Figure 4-1)

GAS IN GAS OUT

The GAS IN and GAS OUT fittings have 5/8-18 right-

hand threads. Obtain proper size, type, and length

hose, and make connections as follows:

1. Connect hose from shielding gas supply regulator/

flowmeter to GAS IN fitting.

2. Connect shielding gas hose from torch to GAS OUT

fitting.

3-12. COOLANT CONNECTIONS (Optional)

(Figure 4-1)

COOLANT IN COOLANT OUT

CAUTION: OVERHEATING Gas Tungsten

Arc Welding (GTAW) torch can damage

torch.

• If using a water-cooled torch and recirculating

coolant system, make connections from the

coolant system directly to the torch hoses. Do

not use water connections on the TIG-Unit.

The COOLANT IN and COOLANT OUT fittings have

5/8-18 left-hand threads. Obtain proper size, type, and

length hose, and make connections as follows:

1. Connect hose from coolant supply to COOLANT IN

fitting.

2. Connect coolant hose from torch to COOLANT

OUT fitting.

3-13. 115 VOLTS AC DUPLEX RECEPTACLE AND

CIRCUIT BREAKER (Figure 4-1)

ON OFF

115V 15A AC

OVERLOAD

PRESS TO START

A grounded duplex receptacle, located behind the front

access door of the TIG-Unit, is provided to furnish up to

2 kva of 115 volts ac to operate external accessories. A

15 ampere circuit breaker, located next to the recep-

tacle, protects this circuit in case overloading of the du-

plex receptacle occurs.