OM-530 Page 22

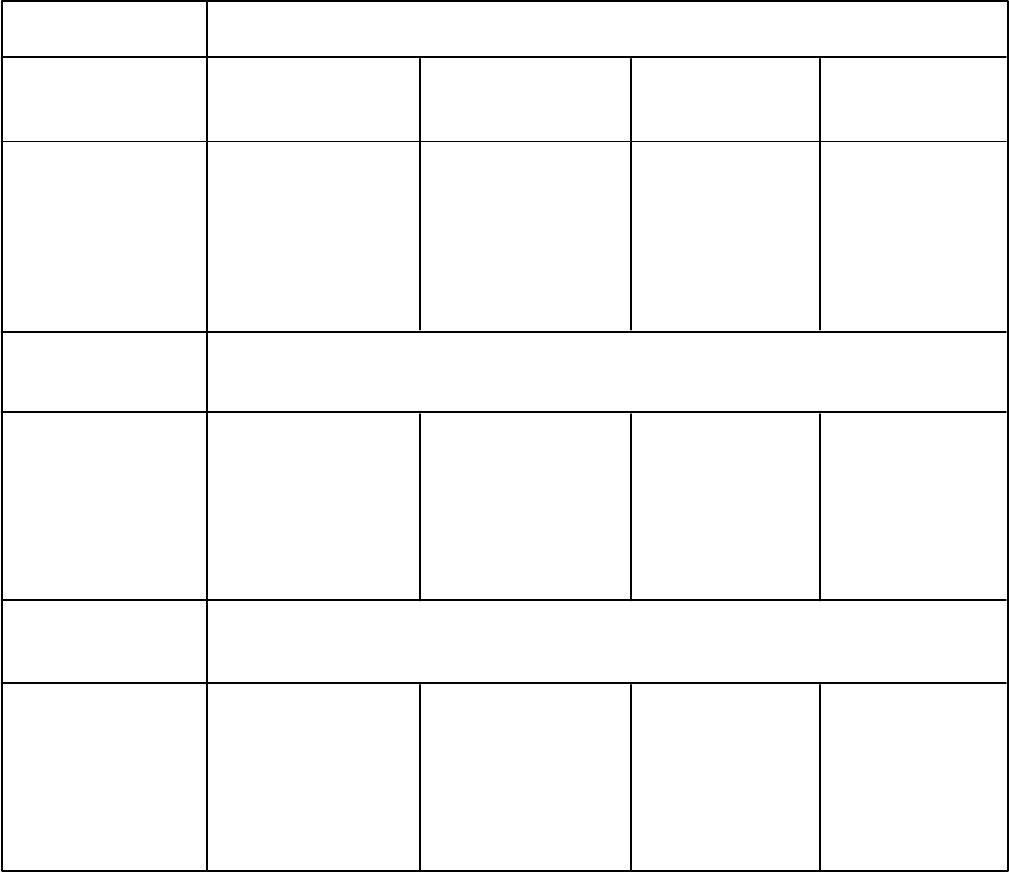

Table 6-2. Tungsten Size Chart

Electrode Diameter

Pure Tungsten

.010”

.020”

.040”

1/16”

3/32”

1/8”

5/32”

3/16”

1/4”

2% Thorium Alloyed

Tungsten

.010”

.020”

.040”

1/16”

3/32”

1/8”

5/32”

3/16”

1/4”

Zirconium Alloyed

Tungsten

.010”

.020”

.040”

1/16”

3/32”

1/8”

5/32”

3/16”

1/4”

Amperage Range - Polarity - Gas Type

DC-Argon Electrode

Negative/Straight Polarity

Up to 15

5-20

15-80

70-150

125-225

225-360

360-450

450-720

720-950

Up to 25

15-40

25-85

50-160

135-235

250-400

400-500

500-750

750-1000

DC-Argon Electrode

Positive/Reverse Polarity

*

*

*

10-20

15-30

25-40

40-55

55-80

80-125

*

*

*

10-20

15-30

25-40

40-55

55-80

80-125

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

AC-Argon Using

High Frequency

Up to 15

5-20

10-60

50-100

100-160

150-210

200-275

250-350

325-450

Up to 20

15-35

20-80

50-150

130-250

225-360

300-450

400-500

600-800

Up to 20

15-35

20-80

50-150

130-250

225-360

300-450

400-550

600-800

AC-Argon Balanced

Wave Using High Freq.

Up to 10

10-20

20-30

30-80

60-130

100-180

160-240

190-300

250-400

Up to 15

5-20

20-60

60-120

100-180

160-250

200-320

290-390

340-525

Up to 15

5-20

20-60

60-120

100-180

160-250

200-320

290-390

340-525

*NOT RECOMMENDED

The figures listed are intended as a guide and are a composite of recommendations from American Welding

Society (AWS) and electrode manufacturers.

S-0009/8-88

(Green Band)

(Red Band)

(Brown Band)

6-3. SPARK GAP ADJUSTMENT (Figure 6-3)

It is necessary to readjust the spark gaps every three to

four months or when intermittent operation occurs. Nor-

mal spark gap setting is 0.008 in. (0.203 mm).

High-frequency output varies with the spark gap setting.

When a great amount of high frequency is necessary,

the spark gaps can be adjusted to 0.010 in. (0.254 mm).

This, however, increases high-frequency radiation

which increases interference with communications

equipment. It is suggested that a minimum spark gap

setting be used.

IMPORTANT: Spark gaps widen with normal operation.

At regular inspections, check and maintain the spark air

gap to ensure consistent welding results and com-

pliance with FCC radiation regulations.

IMPORTANT: Do not clean or dress points since the

material at the tips is tungsten and impossible to file.

The entire point should be replaced when the tungsten

section has completely disappeared.

This unit is provided with a spark gap assembly located

inside the unit in the lower right side (refer to Parts List

views). To adjust spark gaps, proceed as follows: