OM-1314 Page 16

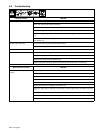

2-11. Weld Parameters

Wire Type, Wire

Material Thickness

Wire Type,

Shielding Gas,

And Flow Rate

Wire

Diameter

(inch)

Operator

Controls

1/4 in.

(6.4 mm)

3/16 in.

(4.8 mm)

1/8 in.

(3.2 mm)

14 ga. 16 ga. 18 ga. 20 ga. 22 ga.

Voltage Tap – – 5 4 3 3 2 2 1

.023

Wire Speed – – 70 60 50 30 20 5 0

E70S-6

Voltage Tap 6 5 4 3 3 2 1 – –

CO

2

20 cfh+

.030

Wire Speed 60 45 40 35 30 25 20 – –

20 cfh+

Voltage Tap 6 5 4 3 2 2 2 – –

.035

Wire Speed 30 20 20 20 20 15 5 – –

Voltage Tap 6 5 4 3 3 2 2 1

.023

Wire Speed 100 90 75 60 50 35 20 10

E70S-6

75% Argon

Voltage Tap 6 5 4 3 3 2 1 1

75% Argon

25% CO

2

.030

Wire Speed 70 60 50 40 30 20 10 0

20 cfh+

Voltage Tap 6 5 5 4 3 2 2 – –

.035

Wire Speed 50 45 40 30 25 25 10 – –

Voltage Tap 6 6 5 4 3 2 2 – –

E71T-GS

.030

Wire Speed 50 45 30 20 20 10 10 – –

E71T-GS

Flux Core

Voltage Tap 6 6 5 4 3 – – – – – –

.035

Wire Speed 40 40 30 20 20 – – – – – –

Voltage Tap – – 5 4 4 3 3 3 3

ER 308

Stainless Steel

.023

Wire Speed – – 100 90 75 60 50 40 25

Stainless Steel

Tri-Mix

Voltage Tap – – 6 5 4 3 3 – – – –

20 cfh+

.030

Wire Speed – – 75 70 60 50 40 – – – –

*Do not change Voltage switch position while welding. Wire Speed value in Table is a starting value only, and Wire Speed control setting can be fine

tuned during welding. S-181 186

SECTION 3 – OPERATION

3-1. Controls

Ref. ST-182 986-B

1 Wire Speed Control

Use control to select a wire feed

speed. As Voltage switch setting in-

creases, wire speed range also in-

creases.

2 Voltage Switch

The higher the selected number,

the thicker the material that can be

welded. Do not switch while

welding.

3 Power Switch

1

2

3