OM-223 839 Page 18

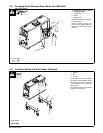

4-12. Selecting Synergic Pulsed MIG Welding

Set Synergic Pulsed MIG welding process on the

power source. L7 is On.

Synergic Pulsed MIG welding is a high quality

welding process that produces very little spatter.

This process works well on thin metals such as

stainless steel and aluminum. In Synergic

Pulsed MIG mode, the operator may need to ad-

just welding data (wire type, wire diameter, and

gas type) and only one weld parameter. General-

ly, wire feed speed is adjusted and the synergic

process automatically sets appropriate weld

voltage. Synergic welding also sets many sec-

ondary welding parameters automatically for im-

proved weld quality.

Trim parameter appears on D1 and D2:

D1 value is default trim setting of 0.0 T (range is

−5.0 T to 5.0 T).

D2 value is default wire feed speed setting of 5.0

m/min (minimum (MIN), maximum (MAX), or de-

fault (DEF) values are arbitrary based on set

welding data). Use P2 and E2 to change this dis-

play to amperes or to the thickness of the weld.

While Setting Parameters:

- L2 ON means that D1 shows Trim value.

- L3 ON means that D2 shows the wire speed in

meter/min or inch/min.

- L4 ON means that D2 shows the set welding

current in amperes.

- L5 ON means that D2 shows the thickness of

material to weld.

While Welding:

- D1 shows the measured welding voltage in

Volts. L1 is ON.

- D2 shows the measured welding current in am-

peres. L4 is ON.

Set wire speed, welding current or material thick-

ness and welding voltage with E2 and E1.

Select trigger mode using P1 pushbutton (see

Section 4-4).

If necessary, use P2 to adjust the welding pa-

rameters.

Purge air from gun hose using P3 pushbutton

(see Section 4-8).

Setting Trim

See Section 4-11.

Synergic Pulsed MIG Welding Advanced Set-

tings

To change all values list, unit must be SETUP

FULL. To set unit to SETUP FULL, proceed as

follows:

Press P2 to enter SET UP menu.

Select SETUP FULL on D1 and D2 (see Section

4-6).

Setting Main Welding Regulation

See Section 4-11.

Setting Inductance in Synergic Pulsed MIG

Welding

Press P2 to enter SET UP menu.

Use E1 to select on D1 ind. D2 shows 100.

If necessary, use E2 to adjust inductance value

(range is 1% to 200%).

This parameter is related to Pulse Width. Higher

values give a hotter welding arc.

. Change these parameters as little as pos-

sible because the factory settings are pre-

ferred for most applications.

Big changes can affect the arc stability and

weld performance.

In general, remain in the 70% to 130%

range.

Wire Feed Speed Unit (only in SETUP FULL)

See Section 4-10.

Setting Pre-Gas (only in SETUP FULL)

See Section 4-10.

Setting Post-Gas (only in SETUP FULL)

See Section 4-10.

Setting Burnback (only in SETUP FULL)

See Section 4-10.

Setting Run-In (only in SETUP FULL)

See Section 4-10.

Setting 3 Level Trigger Mode

See Section 4-11.

Setting Synergic Double Pulsed MIG

. Synergic Double Pulsed MIG process is se-

lected at the power source or recalled in the

wire feeder using Synergic Double Pulsed

programs. All Double Pulse parameters are

selected on the wire feeder. All other MIG

parameters are the same as standard

Pulsed MIG process.

Some metals weld better using the Synergic

Pulsed Welding process due to the unique puls-

ing of the welding arc. Heat generated in the

workpiece is generally lower and the arc charac-

teristics produce a better weld bead appearance

especially on aluminum. The Synergic Double

Pulsed MIG process allows control all parame-

ters to produce high quality welds on aluminum.

. Incorrect settings in Synergic Double

Pulsed Welding process can result in a pro-

gram with undesirable weld characteristics.

Setup should only be used by operators fa-

miliar with various welding processes and

parameters. In some cases, standard Syn-

ergic Pulsed MIG welding can produce bet-

ter welds.

Press P2 to enter SET UP menu.

Use E1 to change D1 to 2P.F.

Use E2 to change D2 value.

The range of this setting is 0.1 Hz to 5.0 Hz. This

setting allows changing double pulse frequency

in hertz (cycles per second). A recommended

frequency is approximately 1 hertz.

Use E1 to change D1 to 2P.C.

D2 value is default setting of 50%.

Use E2 to change D2 value.

The range of this setting is 25% to 75%. This set-

ting allows changing the time that the pulse is at

high output. A lower setting will produce less

heating at the welding puddle.

Use E1 to change D1 to 2P.O. D2 value is default

setting of 20%. Use E2to change D2 value. The

range of this setting is 20% to 80%. This setting

allows changing the difference in high wire feed

speed and low wire feed speed in percent of the

wire feed speed setting. For example, if the main

wire feed speed is set at 5 M and 2P.0 setting in

D2 is 40%, the wire feed speed will change be-

tween 4 m/min and 6 m/min. A recommended

setting is 20%.

Use E1 to change D1 to 2P.A. D2 value is the de-

fault setting of 0.0. Use E2 to change D2 value.

The range of this setting is −5.0 to 5.0.

This setting allows changing the low end of trim

in double pulse and the main setting for trim will

be the low end. A higher 2P.A setting will produce

a longer and hotter arc and lower setting will pro-

duce a shorter and cooler arc.

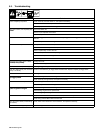

E1 D1 D2 E2

P1 P2 P3

L1

L2 L3 L4 L5

L7

L8