OM-223 839 Page 19

SECTION 5 − MAINTENANCE & TROUBLESHOOTING

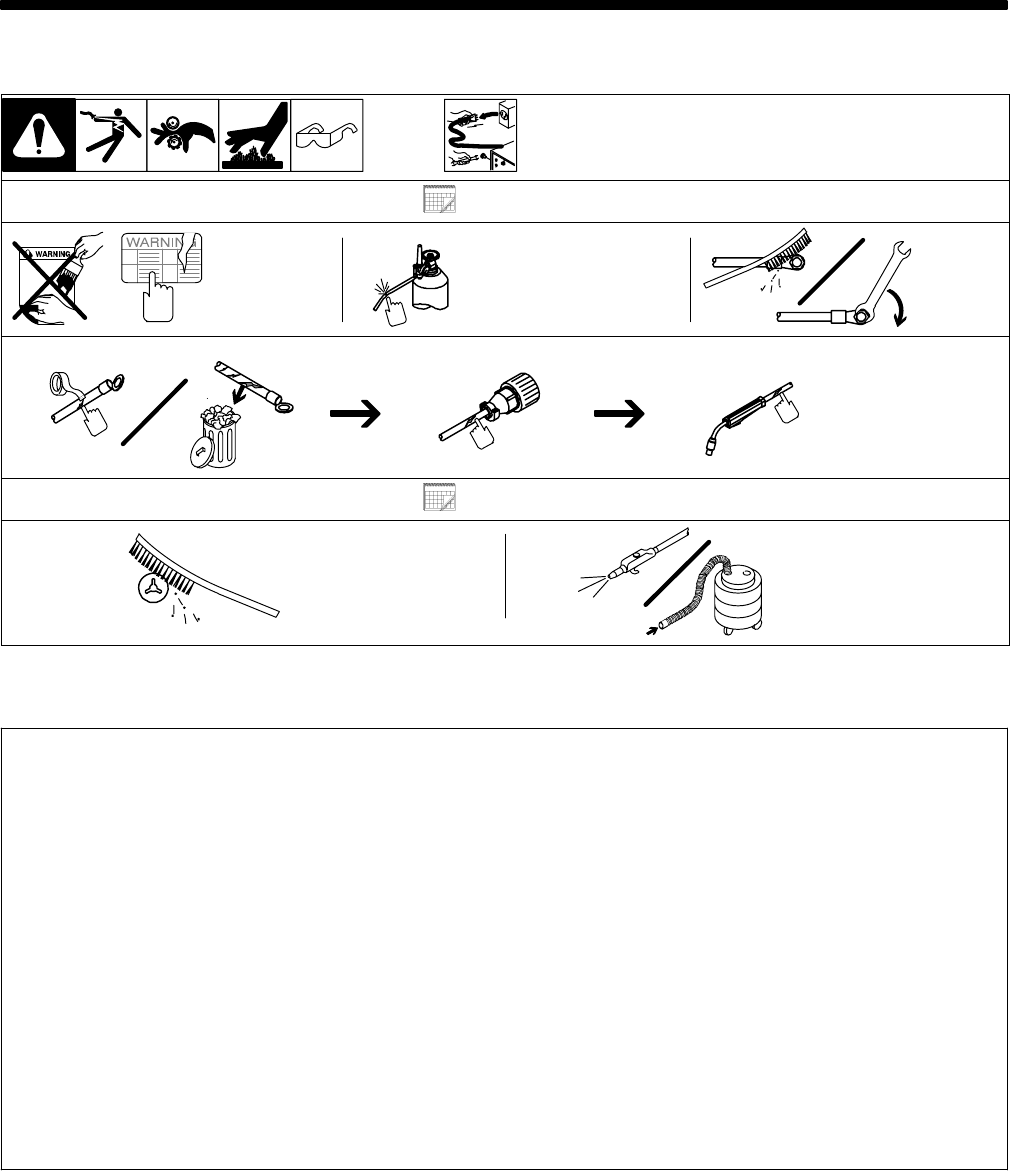

5-1. Routine Maintenance

Y Disconnect power

before maintaining.

. Maintain more often

during severe conditions.

3 Months

Replace

Damaged Or

Unreadable

Labels

Clean And

Tighten

Weld

Terminals

Replace Damaged

Gas Hose

Repair Or Replace

Cracked Cables

And Cords

6 Months

Clean

Drive

Rolls

Blow Out Or

Vacuum Inside

5-2. Help Displays

The XMC 44 microprocessor controls all internal parameters of the

units.

In case of failure, D1 and D2 will show the following Error Signals.

HLP 100

Indicates that the 24 volt AC supplied to the unit is low.

Verify the supply to the unit and the circuit breaker status on both the

wire feeder and on the power source.

HLP 101

Indicates that the current in the motor is too high.

Verify that the wire has not stopped.

HLP 102

Indicates that the voltage on the motor is too high.

Verify that the wire has not stopped.

HLP 103

Indicates that there is a short circuit in the motor or in the cabling.

Verify that the motor and cabling are functioning.

HLP 104

Indicates that the motor speed is too low or the encoder on the motor

is giving incorrect signals.

Verify that the motor has not stopped and check the cabling of the en-

coder.

HLP 105

Indicates a communication error between the power source and the

wire feeder.

Verify that all the connectors in the path from the control board of the

power source and the motor board of the wire feeder are correctly

fixed.

HLP 106

Indicate that there is a communication error in the RS 485.

Verify that all the connectors in the path from the control board of the

power source and the motor board of the wire feeder are correctly

fixed.