OM-2254 Page 23

SECTION 6 − OPERATION

ARC CONTROL

ELECTRODE HOT

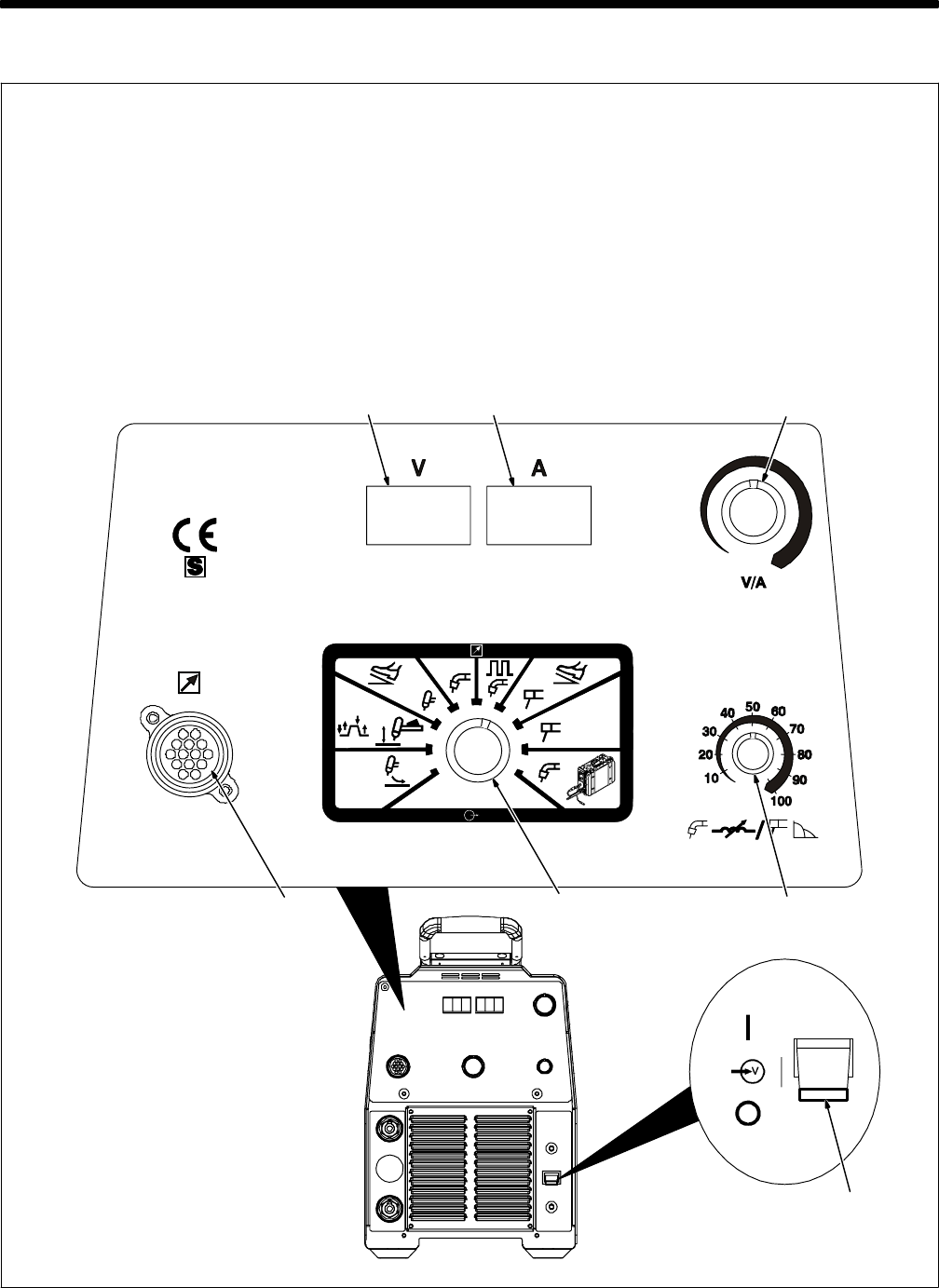

6-1. Front Panel Controls

1 Power Switch

. The fan motor is thermostatically

controlled and only runs when cooling is

needed.

2 Voltmeter

3 Ammeter

4 V/A (Voltage/Amperage) Adjustment

Control

5 Mode Switch

The Mode switch setting determines both the

process and output On/Off control (see Sec-

tion 6-3).

For Air Carbon Arc (CAC-A) cutting and goug-

ing, place switch in Stick position. For best re-

sults, place Arc Control in the maximum posi-

tion.

6 Remote 14 Receptacle

For remote control, make connections to Re-

mote 14 receptacle. In TIG modes and the

REMOTE STICK mode, remote control is a

percent of V/A Adjust control setting (value

selected on V/A Adjust is maximum available

on remote). In ELECTRODE HOT STICK

mode the remote control is not used. In the

MIG mode, remote control provides full range

of unit output regardless of V/A Adjust control

setting.

7 Arc Control

Control adjusts Dig when Stick or CC mode is

selected on mode switch. When set towards

minimum, short-circuit amperage at low arc

voltage is the same as normal welding

amperage.

When set towards maximum, short-circuit

amperage is increased at low arc voltage to

assist with arc starts as well as reduce stick-

ing while welding.

Select setting best suited for application.

Control adjusts inductance when MIG or

V-Sense Feeder position is selected on the

mode switch. Inductance determines the

“wetness” of the weld puddle. When set to-

wards maximum, “wetness” (puddle fluidity)

increases.

When Pulsed MIG or one of the TIG modes is

selected, this control is not functional.

23 4

5

7

6

Ref. 803 692-B / Ref. 219 341-A

1