OM-2254 Page 25

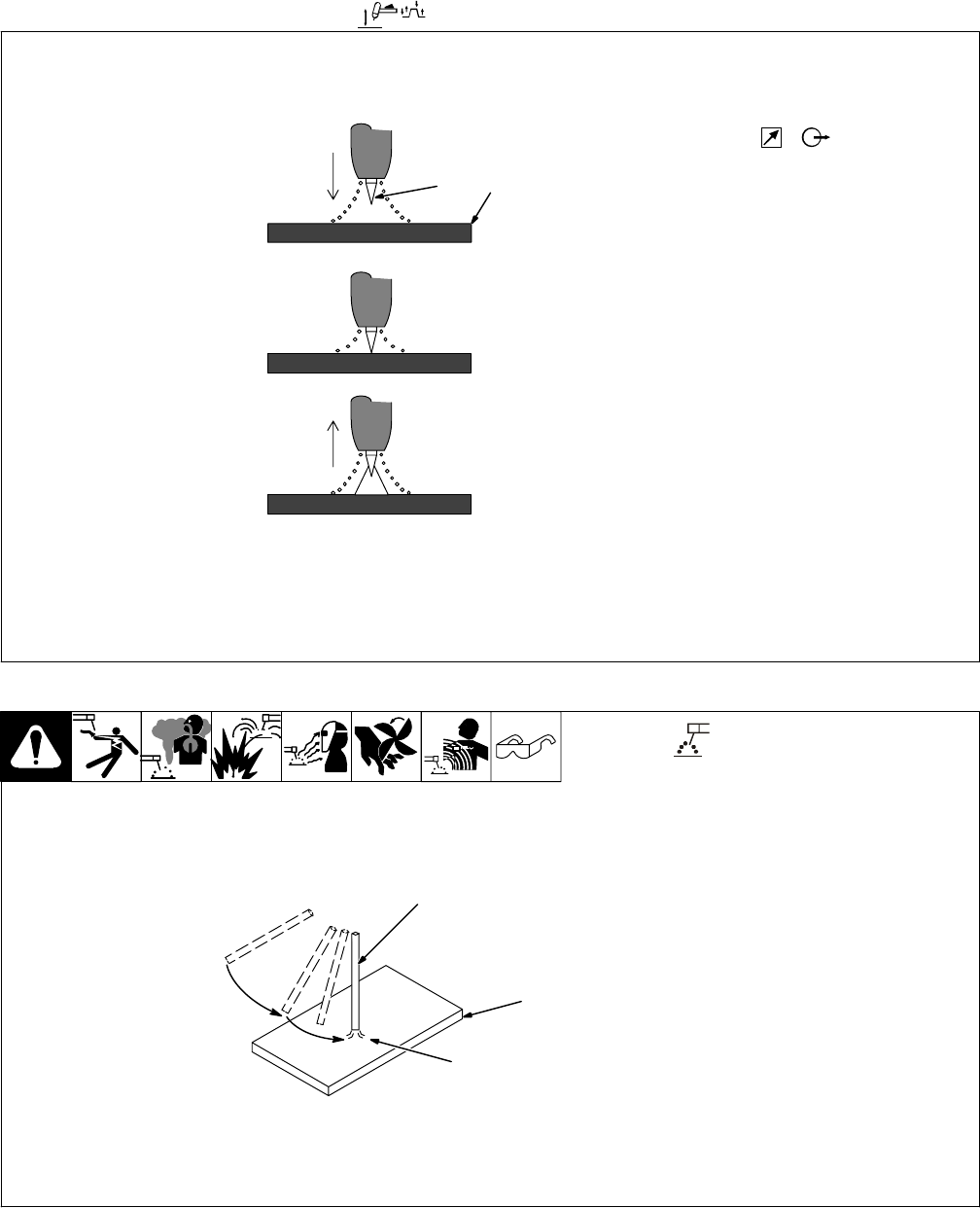

6-4. Lift-Arc Trigger Hold TIG

1 TIG Electrode

2 Workpiece

. Procedure requires:

Start sequence:

• Touch tungsten electrode to

workpiece at weld start point.

• Momentarily depress output

switch.

• Slowly lift electrode. An arc will

form when electrode is lifted.

• To stop welding, momentarily

depress output switch and out-

put will shut off.

Note: If output switch is momen-

tarily depressed and tungsten is

not touching workpiece:

Do not touch tungsten to work.

Output will shut off in 3 seconds.

Start sequence over.

1

1 − 2

Seconds

“Touch”

Do NOT Strike Like A Match!

2

Ref. S-156 279

control

6-5. Stick Start Procedure

With Stick selected, start arc as fol-

lows:

1 Electrode

2 Workpiece

3 Arc

Drag electrode across workpiece

like striking a match; lift electrode

slightly after touching work. If arc

goes out electrode was lifted to high.

If electrode sticks to workpiece, use

a quick twist to free it.

Low OCV Stick

The unit can be optionally config-

ured for low open circuit voltage

(OCV) operation. When the unit is

configured for low OCV operation

only a low sensing voltage (approxi-

mately 15 VDC) is present between

the electrode and the workpiece

prior to the electrode touching the

workpiece. Consult a Factory

Authorized Service Agent for infor-

mation regarding how to configure

the unit for low OCV stick welding

operation.

1

2

3