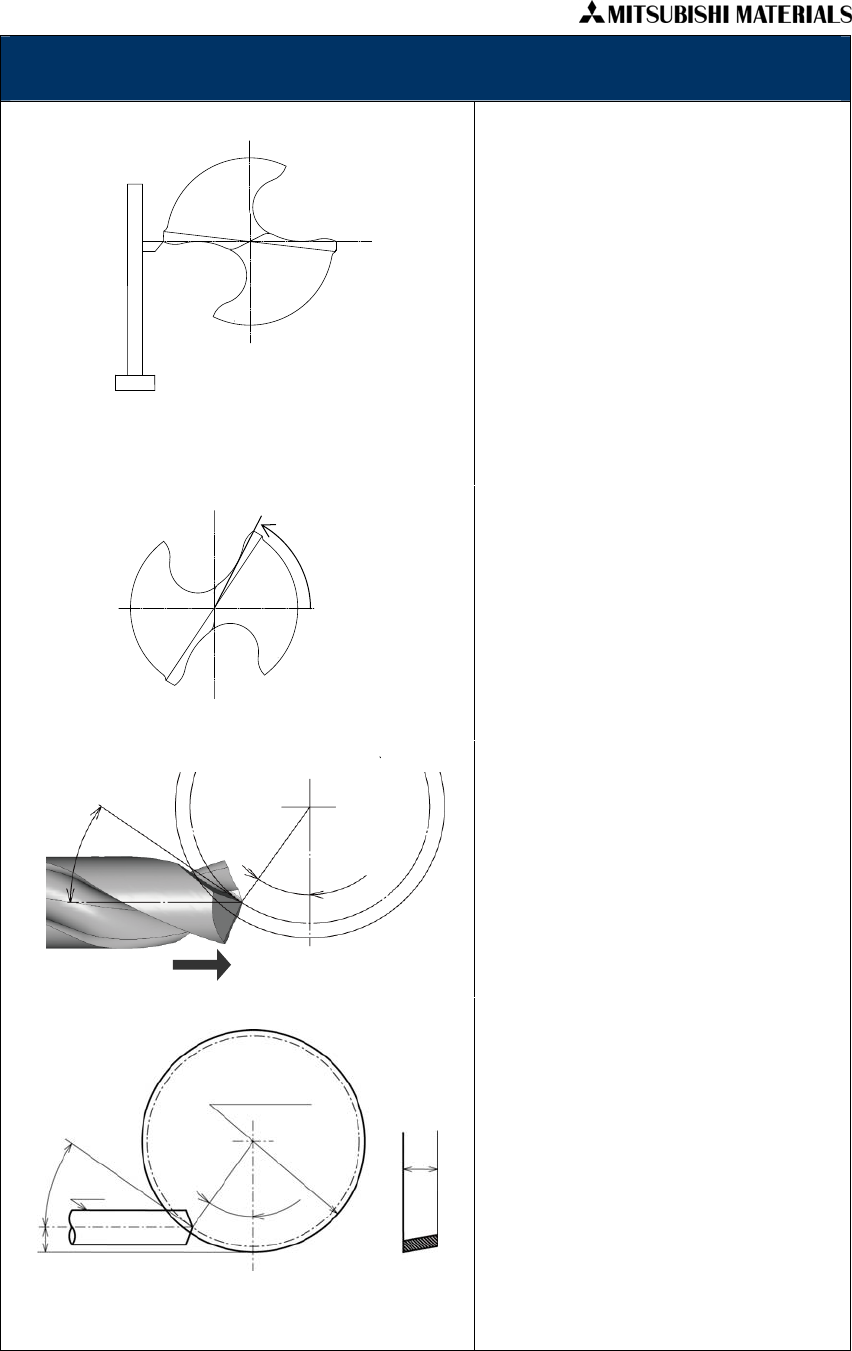

Grinding thinning face

• After grinding second relief face, grind

thinning face. Type of the thinning is

X-thinning.

• First, set the work head horizontal so that

the center of the drill will be horizontal.

Drill rotation angle is 0°. Set the direction

of table oscillation parallel with the center

line of the drill.

• As shown in fig.7, set the drill phase so

that the line connecting the shoulder of

both sides will be horizontal by using a

device such as height gage.

• Then, as shown in fig.8, rotate the drill

counter clockwise 65°when seen from the

top.

• Set the vertical position of the wheel so

that the open angle of the thinning from

the drill center will be 35°, as shown in

fig.9.

• As shown in fig.10, set the wheel height

so that the center line of the drill will be

higher than the bottom of the the wheel

edge by “L”. (Please refer to the formula

in figure 10.)

• As shown in fig.9, grind the thinning face

by sliding the table to the direction shown

by the arrowhead, pressing the drill

against the wheel. Grind slowly adjusting

the top end of cut by using a device such

as a stopper.

Height gage

Fig.7

Fig.8

65°

Fig.9

35°

35°

Cutting direction

L=0.5×φD1×(1-cosθ)+H×tan10°×cosθ

Fig.10

θ

L

Drill

H

35°

Max. wheel diameter φD1

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved