• Adjust the wheel position while grinding

so that the measurements of the thinning

(X part, Y part) will be the same as those

of fig.10. (Dotted lines show the final

positions.

• (Grinding tip) To make the task easy,

grind the two cutting edges alternately,

using a mirror to check the configuration

while grinding.

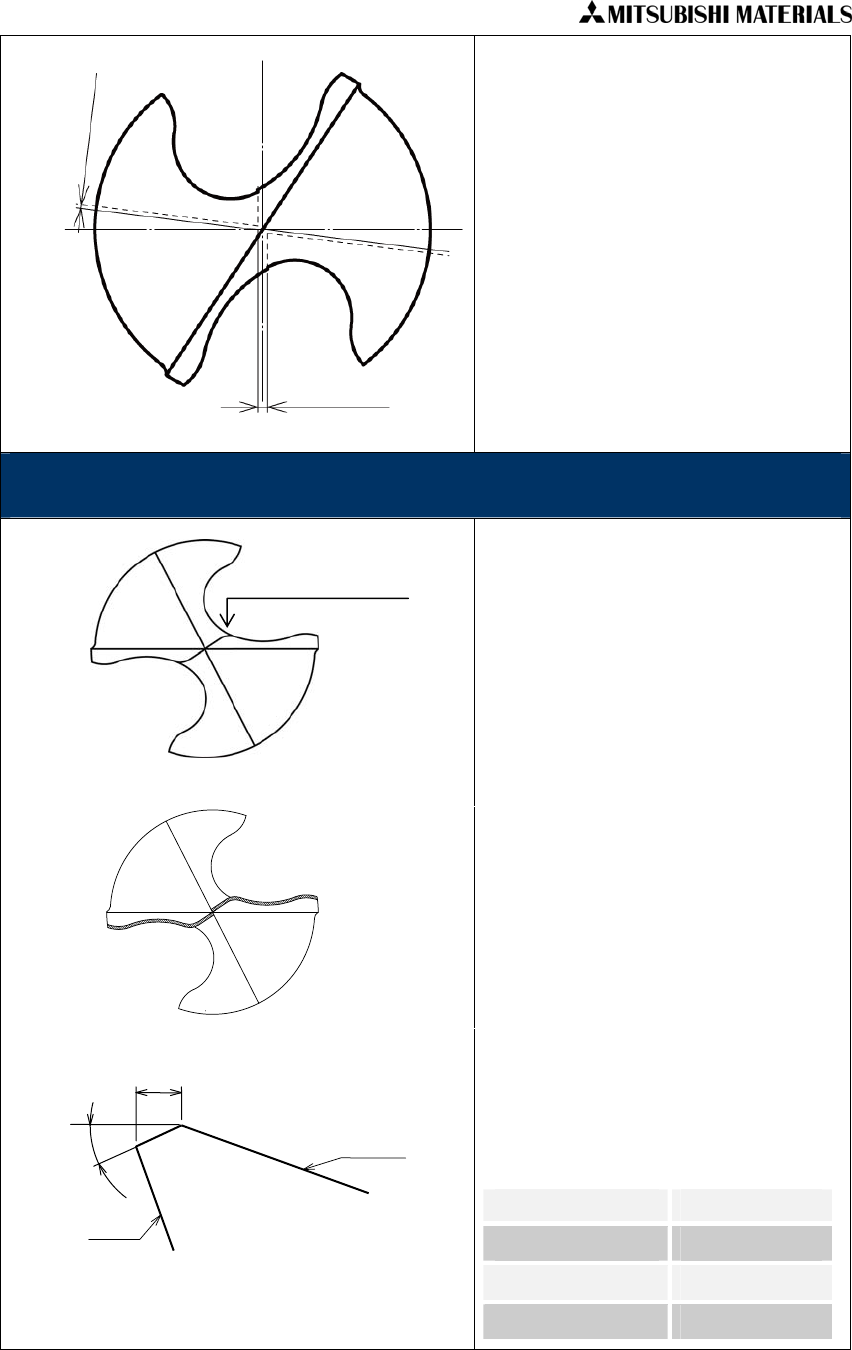

Honing

• After grinding thinning face, grind honed

edges. This is the last procedure for

regrinding.

• First, as shown in fig.11, grind the edge

at the cross section of the thinning edge

and major cutting edge with diamond file

until it becomes R-shaped.

• Appropriate R size is approximately (0.1

~ 0.15) x ØD.

• As shown in fig.12, thoroughly grind

honed edges on both sides evenly. First,

use a diamond file with grain size #400

for honing, and finish by using a hand lap

with grain size #1500.

• As shown in fig.13, honing angle is 25°.

• Change honing width inb accordance

with tool diameter (Please refer to table

1).

Tool diameter φD Honing width W

φ5 less

0.025~0.05

φ5 over φ10 less

0.05~0.1

φ10 over φ20 less

0.10~0.15

0.1~0.2

Y

part

X part

-0.03~0.03

R(0.1~0.15)×φD)

Fig.11

Fig.12

W

Center line of the drill

Rake face

Relief face

25°

Table.1

Unit (mm)

Fig.13

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved