ASSEMBLY INSTRUCTIONS/OPERATION

SFCS-16 OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 12

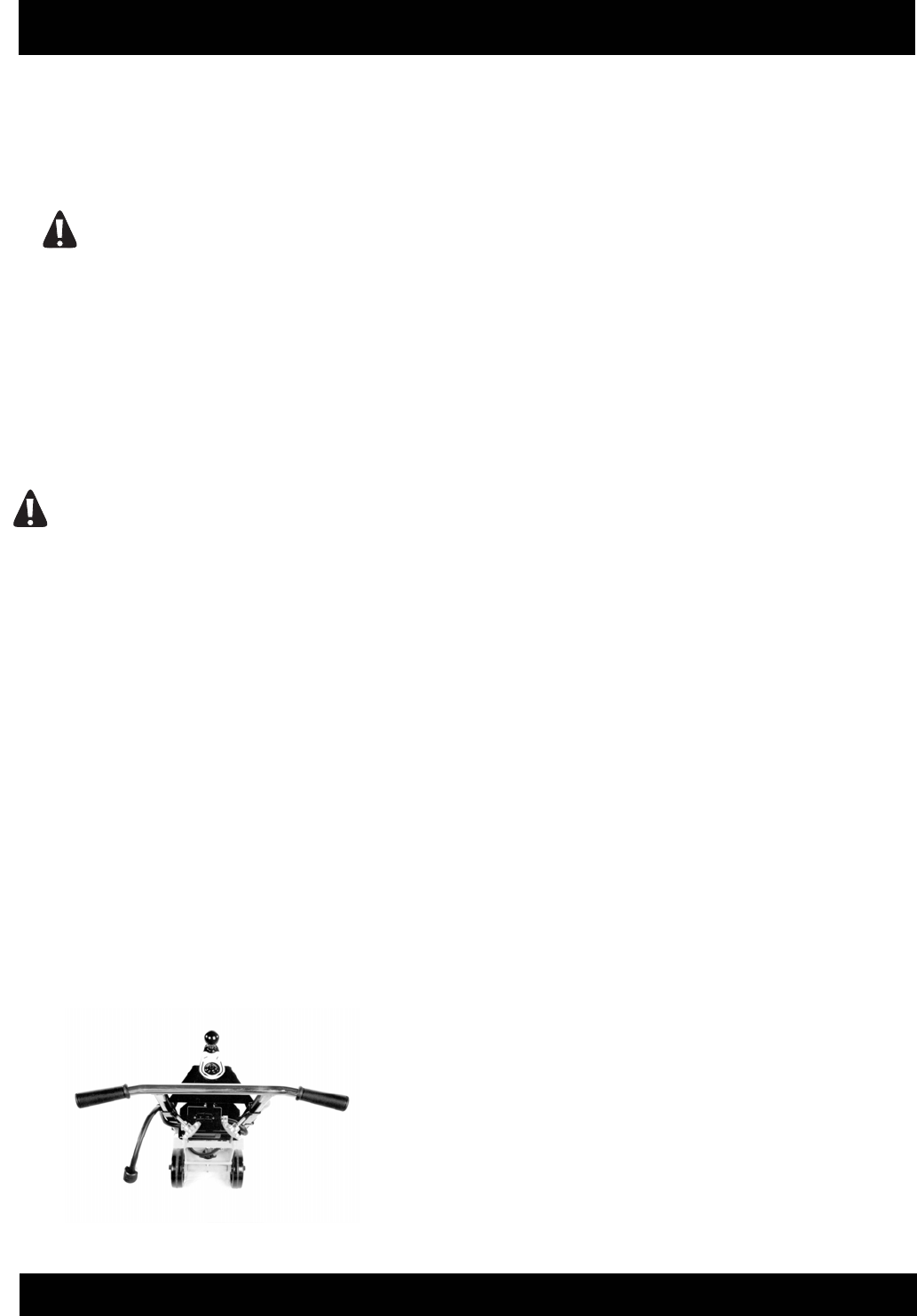

backwards toward the operator. FIGURE 2. Position

the adjustable section at a comfortable height.

Reinstall the threaded knobs and tighten until the

studs trust up tight against the adjustable handle

section.

The ergonomic design considerations of the

adjustable section of the operator handle will only

function if the handle grips are installed facing

backwards (toward) the operator. Installing the

adjustable section of the operator handle with the

handle grips facing forward (away) from the

operator will decrease machine control and

productivity.

INSTALLING THE ADJUSTABLE SECTION OF THE

OPERATOR HANDLE WITH THE HANDLE GRIPS

FACING FORWARD (AWAY) FROM THE

OPERATOR WILL NOT ALLOW THE THREADED

STUDS TO PROPERLY LOCATE WITHIN THE

SLOTS OF THE ADJUSTABLE HANDLE. THE SLOT

ENDS FORM INTEGRAL STOPS FOR THE

THREADED STUDS TO THRUST AGAINST. A

PROPER STUD/SLOT CONFIGURATION WILL

PREVENT THE ADJUSTABLE HANDLE FROM

INADVERTENTLY SEPARATING FROM THE FIXED

SECTION WHEN TRAVERSING AN INCLINE SUCH

AS A STAIRWAY. INADVERTENT SEPARATION OF

THE ADJUSTABLE HANDLE SECTION CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

Improper knob tension and/or improperly securing

the operator handle to the main frame can result in

an unstable platform configuration. An unstable

platform configuration can result in property

damage and/or personal injury.

FIGURE 2

Before Starting the Motor

THEORY OF OPERATION.

The SFCS16 FLOOR COVERING SCRAPER is

designed to operate on the principle of various blades

and/or attachments oscillating with a random orbital

movement to remove a wide variety of covering

materials from work surfaces. Various types of multi-

accessory blades and/or accessory attachments are

secured to the exciter plate located on the bottom of

the machine. The specific type of blade and/or

accessory attachment utilized directly affects the type

of material removed, the material removal rate and the

resulting smoothness of the work surface.

The coverings removal process is directly controlled

by these conditions:

1) The use of a suitable mechanism (blade or

accessory attachment) of proper design and

configuration to scrape against the work surface and

remove material while delivering an acceptable

service life.

2) Sufficient static weight supporting the blade or

accessory attachment to a llow it to effectively

penetrate and remove the covering material.

3) Adequate force exerted against the FLOOR

COVERING SCRAPER by the operator that pushes

the blade or accessory attachment against the

covering material to deliver acceptable productivity

rates.

4) Since no two covering materials are exactly a

like,

no two covering materials can be removed by the

exact same method. The nature of the covering

removal process, along with operator experience, skill

and common sense, would suggest that efficient and

productive material removal is a matter of trial and

error. Combinations of blade or accessory attachment

type, jobsite conditions, and feed rates are direct

factors that will also determine the overall success of

the job application.

BLADE CONFIGURATIONS, ACCESSORY

ATTACHMENTS AND APPLICATIONS.

FLOOR COVERING SCRAPER blades are fabricated

from high carbon steel, precision machined and heat

treated for extended service life. Blades a

re marked to

depict use on either concrete or wood surfaces. When

utilized on concrete, the cutting edge is positioned

facing up. FIGURE 3. On wood flooring surfaces, the

CAUTION

CAUTION