ASSEMBLY INSTRUCTIONS/OPERATION

SFCS-16 OPERATION AND PARTS MANUAL REV #4 (05/28/09) PAGE 18

CAUTION

Improper knob tension and/or improperly securing

the operator handle to the main frame can result in

an unstable platform configuration. An unstable

platform configuration can result in property

damage and/or personal injury.

FIGURE 16

4) Tilt the FLOOR COVERING SCRAPER back until

the operator handle comes in contact with the surface.

The FLOOR COVERING SCRAPER may not be in a

stable position in this configuration. To minimize the

possibility of property damage a nd/or persona l injury,

properly secure an appropriate weight to the handle

for added stability. Other means can also be utilized to

support the frame and provide proper machine

stability. Appropriate wheel chocks are also

recommended. FIGURE 17.

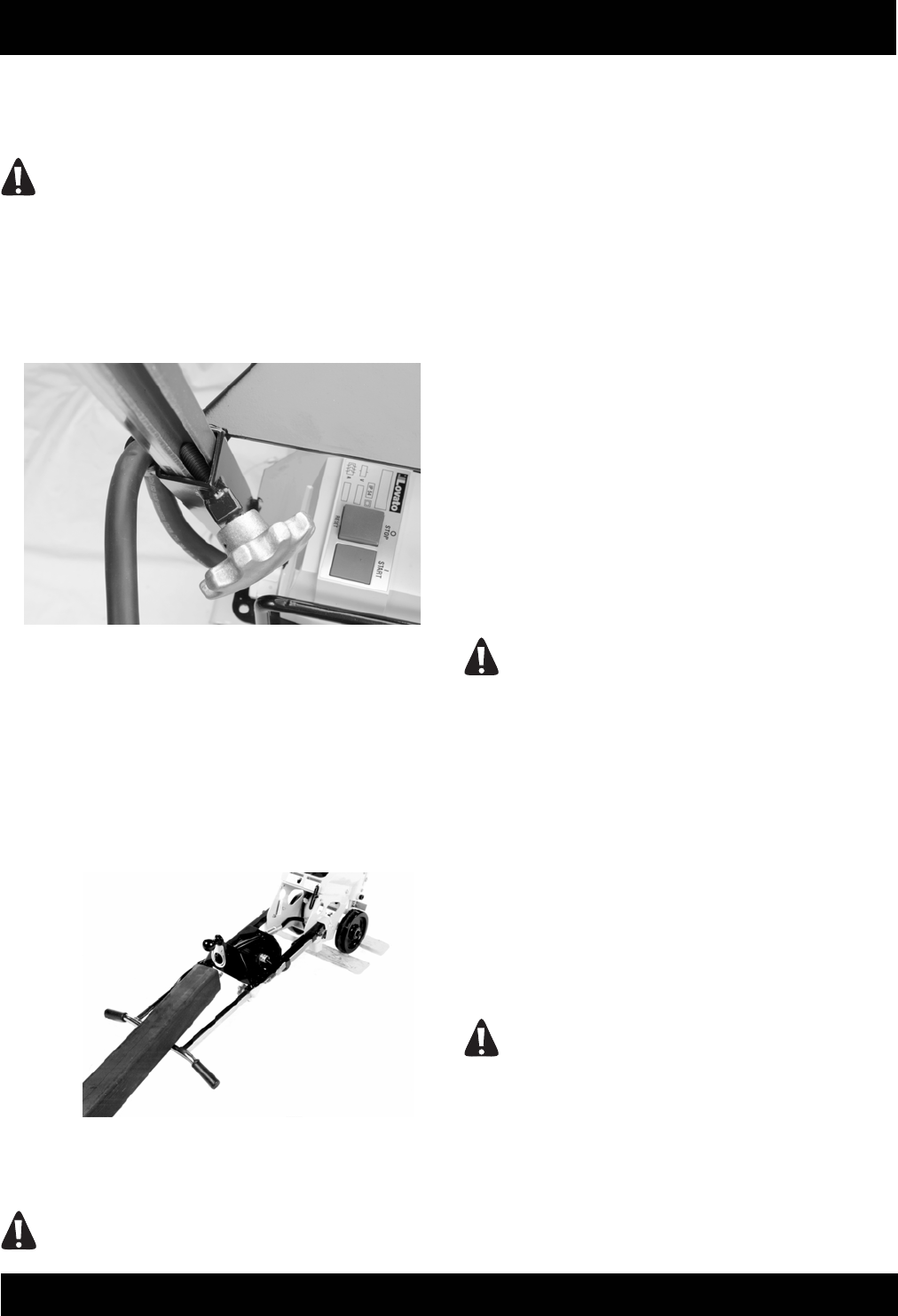

FIGURE 17

DANGER

EXERCISE EXTREME CAUTION WHEN WORKING

NEAR OR UNDER THE FLOOR COVERING

SCRAPER WITH THE OPERATOR HANDLE TILTED

BACK IN THE SERVICE POSITION. IF THE FLOOR

COVERING SCRAPER IS NOT POSITIONED IN A

STABLE CONFIGURATION, WITH ADEQUATE

COUNTERWEIGHT PROPERLY SECURED,

UNEXPECTED MOVEMENT CAN ALLOW THE

MACHINE TO FALL BACK TO THE WORK

SURFACE. THE RESULT CAN BE PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

5) Reinstall the protective blade cover. Exercise

extreme caution when removing and/or reinstalling the

protective cover. Use the T-handled Allen wrench to

loosen the button head capscrews which secure the

blade between the fence plate and exciter plate.

Remove the blade and store in an appropriate

location. Use the T-handled Allen wrench to tighten

the button head capscrews. Keep the button head

capscrews tight to minimize becoming lost.

6) The removal of the ceramic tile ripper attachment is

similar to that of a blade with the exception that the

fence plate is reinstalled to the exciter plate. Follow

the same tightening procedure as with a blade.

CAUTION

For all blades and the ceramic tile ripper

attachment, tighten the button head capscrews

only with the T-handled Allen wrench provided. Do

not utilize another wrench type and/or

configuration. The T-handled Allen wrench was

chosen to place body parts a practical distance

from the blade during the fastener tightening and

loosening process. Do not apply excessive impact

force to the button head cap screws. Ample

seating torque can be applied by the T-handled

Allen wrench. Excessive impact force can cause

the T- handled Allen wrench to slip out of the

button head capscrew, resulting in property

damage and/or personal injury.

CAUTION

Do not substitute a different fastener type for the

button head capscrew configuration. The button

head configuration was chosen for operational

considerations. The use of other fastener types

can increase the potential for property damage

and/or personal injury.