PAGE 18 — TP7X TILE SAW • OPERATION MANUAL — REV. #0 (03/04/11)

SET-UP

BLADES

Blade Components

Diamond blades are recommended for your saw. Ask your

Multiquip dealer about your specific cutting application.

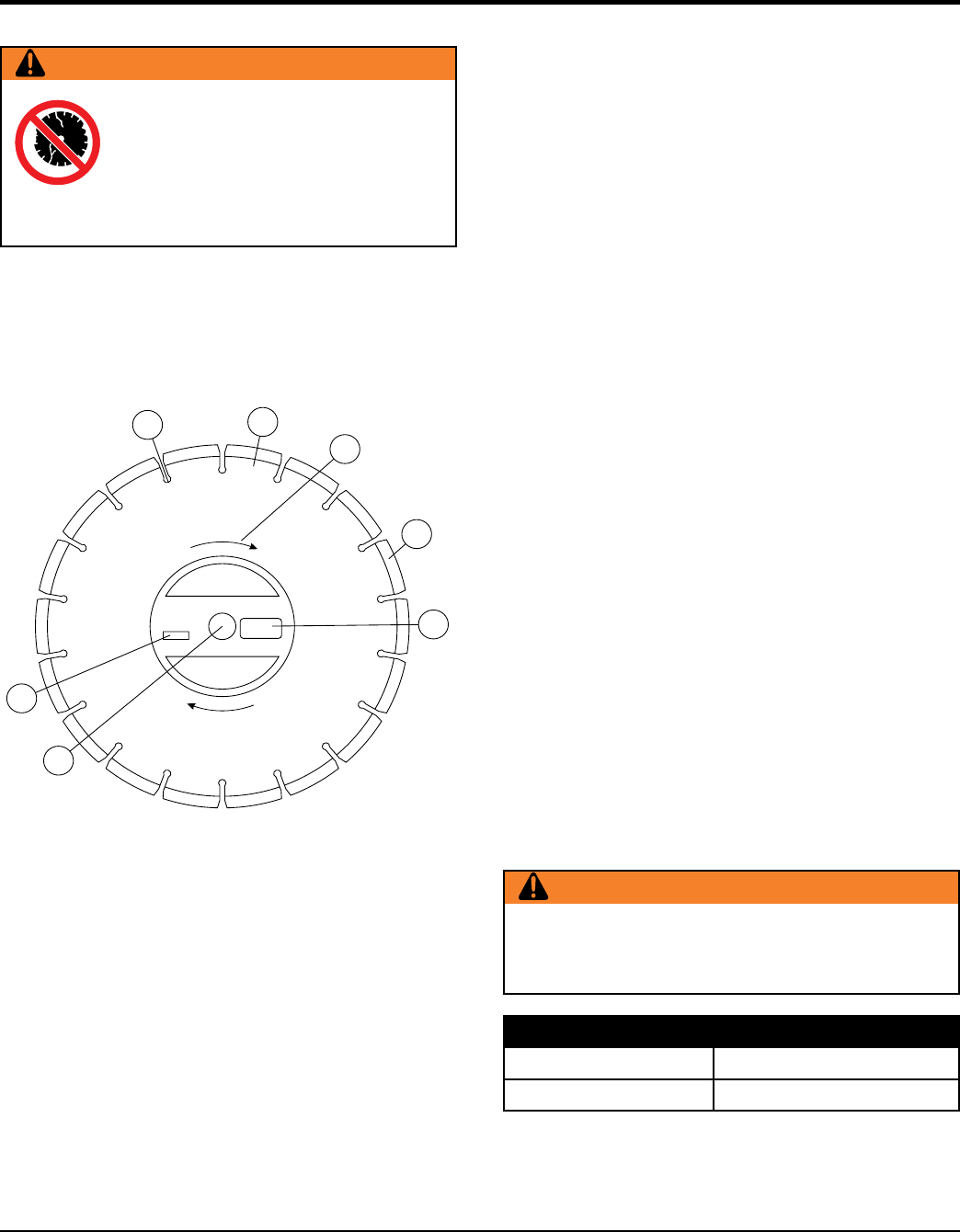

Figure 8 highlights the components of a diamond blade.

Figure 8. Diamond Blade

1. Stress Relief Holes (Gullets) — Check the steel core

for cracks that may have propagated from the slots

and/or gullets. Cracks indicate extreme fatigue failure

and if sawing continues, catastrophic failure will occur.

2. Edge of the Steel Core — Check the diameter edge for

discoloration (blue oxidation) indicating an overheating

condition caused by insufficient cooling water/air.

Overheating of blades may lead to loss of core tension

and/or increase the possibility for blade failure. Check

to make sure the steel core’s width is uniform about

the rim of the blade, and not succumbing to an “under

cutting” condition brought about by highly abrasive

material or improper under cutting core protection.

WARNING

Failure to thoroughly inspect the blade for

operational safety could result in damage to

the blades or the saw and may cause serious

injury to the user or others in the operating

area. Inspect the blade flanges and shaft for

damage before installing the blade.

MAX.RPM

SPECIFICATIONS

1

2

3

4

5

6

7

3. Directional Arrow — Check to ensure that the blade is

oriented properly on the spindle for sawing. Reference the

directional arrow on the blade and place it so the direction

of rotation “downcuts” with the turn of the shaft.

4. Diamond Segment or Rim — Ensure that there are

no cracks, dings, or missing portions of the diamond

segment/rim. DO NOT use a blade that is missing

a segment or a portion of the rim. Damaged and/or

missing segments/rims may cause damage to your saw

and injury to the user or others in the operating area.

5. Specifications — Ensure that the blade specifications,

size, and diameter properly match up to the sawing

operation. Wet blades must have water to act as a coolant.

Utilizing a diamond blade not matched properly to the task

may result in poor performance and/or blade damage.

6. Arbor Hole — It is essential that the arbor hole

diameter properly matches the shaft arbor, and that it

is free from distortions. Correct blade flanges (collars)

must be used. The inside face of the flanges must be

clean and free of debris. An out of round arbor condition

will cause damage to the blade and the saw.

7. MAX RPM — This RPM reference is the maximum safe

operating speed for the blade selected. NEVER exceed

the max RPM on the diamond blade. Exceeding the MAX

RPM is dangerous, and may cause poor performance

and may damage the blade. All blades used must be

designed for the maximum spindle RPM.

Cutting Depth

The recommended cutting depth is 1/4" (6 mm) below the

cutting table surface. To adjust the cutting depth, loosen the

cutting head adjustment knob so that the blade is 1/4" below

the top of the cutting table's surface. See Table 4 to determine

cutting depth by blade diameter.

WARNING

Setting the blade too low may damage the cutting table

and if set too high, the blade may grab the material

being cut, causing damage and possibly injury.

Table 4. Blade Diameter vs. Cutting Depth

Blade Diameter Cutting Depth

7 in. (178 mm) 1-3/4 in. (44.5 mm)