15-ENG

Every 160 Hours of Operation:

1. Check drive belt tension; adjust if necessary.

2. Inspect air lines and fittings for leaks; correct as necessary.

3. Check the alignment of the motor pulley to the flywheel. If necessary, align to

within 1/32 inch on center line.

Each Year of Operation or if a Problem is Suspected:

Check condition of air compressor pump intake and exhaust valves. Replace if

damaged or worn out.

SERVICE INSTRUCTIONS

Air Filter - Inspection and Replacement

NOTE

Keep the air filter clean at all times. Do not operate the air compressor

with the air filter removed.

A dirty air filter will not allow the air compressor to operate at full capacity. Before

you use the air compressor, check the air filter to be sure it is clean. If it is dirty,

replace it with a new filter.

Oil - Checking and Changing

Overfilling with oil will cause premature air compressor

pump failure. Do not overfill.

1. Check oil level in air compressor crankcase before each use. The oil level

should be even with the top of the fill hole and must not be allowed to be lower

than 3/8" from the top (6 threads) at any time.

2. See Routine Maintenance Schedule for oil change scheduling.

3. Remove the oil fill and drain plugs. Collect the oil in a suitable container.

4. Replace the oil drain plug and refill the crankcase with recommended oil.

Note

It is important to maintain the proper oil level. A low oil level reduces

proper cylinder wall lubrication and increases ring wear.

5. Replace the oil fill plug.

6. Start the air compressor unit and run for several minutes. Shut the air

compressor down and check the oil level. If necessary, add more oil.

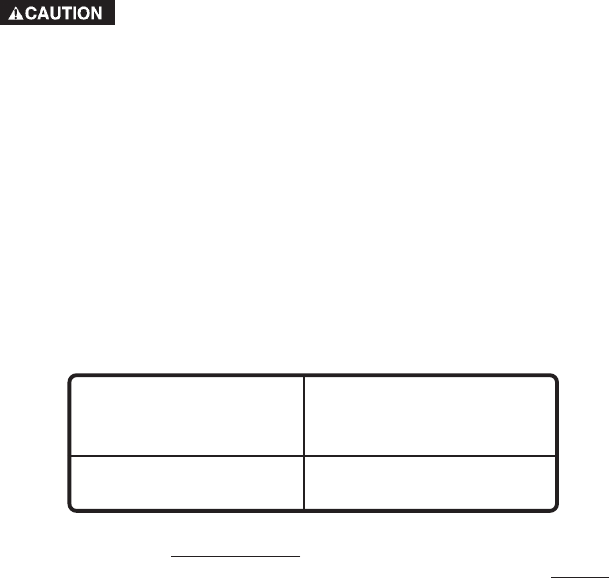

Recommended Oil Room or

(API SG/CD Ambient

Heavy Duty)* Temperature

SAE 10 Below 20

o

F

SAE 20 Above 32

o

F

Viscosity Chart

Oil Capacity

Oil capacity is approximately 16 fluid ounces. The oil level should be even with the

top of the fill hole and must not be allowed to be lower than 3/8" from the top (6

threads) at any time.

Oil Type

An air compressor grade non-detergent oil should be used. Most automotive

detergent oils cause excessive carbon buildup and should not be used. Do not use

synthetic oil for the first 300 hours. All units should be broken in on petroleum

based oil.