10

• The objective is to make the parts fit closely together. Maximize the gluing surface by making the tenon as long as possible

(approximately 1/2 the width of the stile or longer, if using narrow stock). Balance the joint by using the same amount of

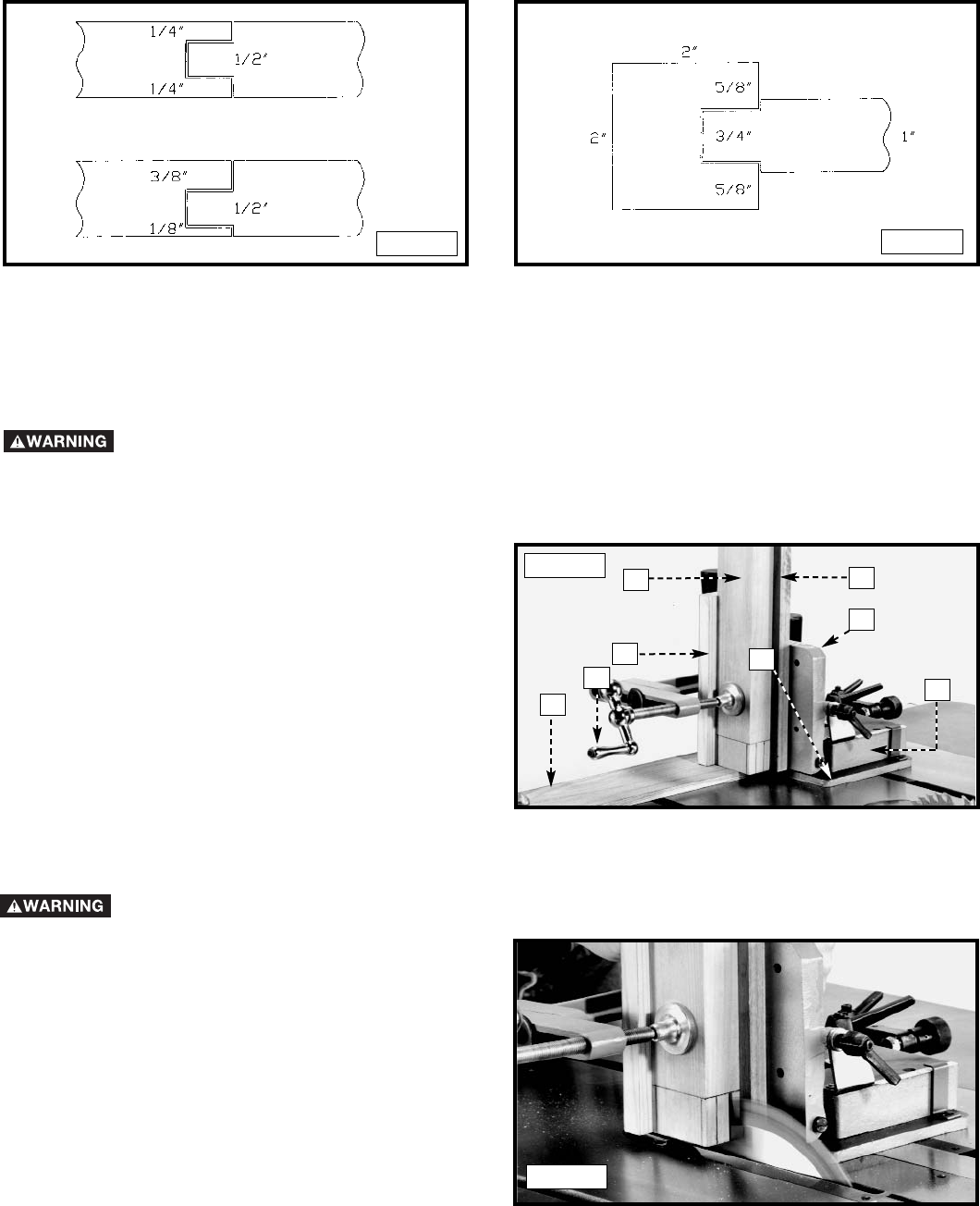

wood in the tenon as in the combined thickness of the mortise walls (Fig. 26). If one piece of wood is larger than the other,

make the tenon as thick as possible (Fig. 27).

• Remember to figure the kerf of the saw blade when setting up for the cut.

• Cut all mortises first. Make the mortise 1/16" deeper than the length of the tenon to allow for glue.

1. Clamp a base stop (F) Fig. 28 (the same thickness as

the base plate (G) of the tenoning jig (H)) on the front of

the saw table. This will allow tenoning jig to pass over

the base stop (F).

2. Make a spacer block of wood (K) Fig. 28, equal to the

thickness of the tenon plus the thickness of the saw

blade.

3. With the tenoning jig (H) Fig. 28 located at the front of

saw table and over the base stop (F), load the spacer

block (K) and the workpiece (L). Securely clamp both in

place with the clamp handle (M). Make certain that both

pieces of wood are against the vertical support plate

(N) and the backup board (P).

4. Gently push the tenoning jig (H) Fig. 28 toward the saw

blade until workpiece is near the saw blade. Adjust the

tenoning jig (H) and the saw blade to make the first

cheek cut. Return the tenoning jig (H) to the front of saw

table.

5. Connect the saw to the power source.

6. Turn the saw “ON” and perform the first structural

cheek cut (Fig. 29). Feed the tenoning jig toward the

saw blade at a slow feed rate until the saw blade has

exited the back of the workpiece. Turn the tool off and

allow the blade to come to a complete stop, then

slowly pull the tenoning jig back to the position shown

in Fig. 28.

Fig. 26

Fig. 27

Fig. 28

You can use several different methods to cut a mortise and tenon. The following information illustrates one of the easiest and

safest methods and utilizes cheek cuts first, then shoulder cuts. Use a base stop (F) Fig. 28 that is the same thickness as

the base plate (G) of the tenoning jig (H) and spacer block (K) that is the combined thickness of the tenon and the saw blade,

to make the cutting more efficient. This method eliminates possible errors caused by thickness variations in the workpiece,

and avoids trapping cut-off pieces between the saw blade and vertical support plate (N).

NOTE: Perform your practice cuts on scrap material before cutting good wood.

Use a slow feed rate to help prevent the tenoning jig from lifting during a cut.

Keep your hands on the jig handles when performing cuts.

Fig. 29

F

K

L

P

M

N

H

G