12

EXAMPLES OF MORTISE-AND-TENON JOINTS

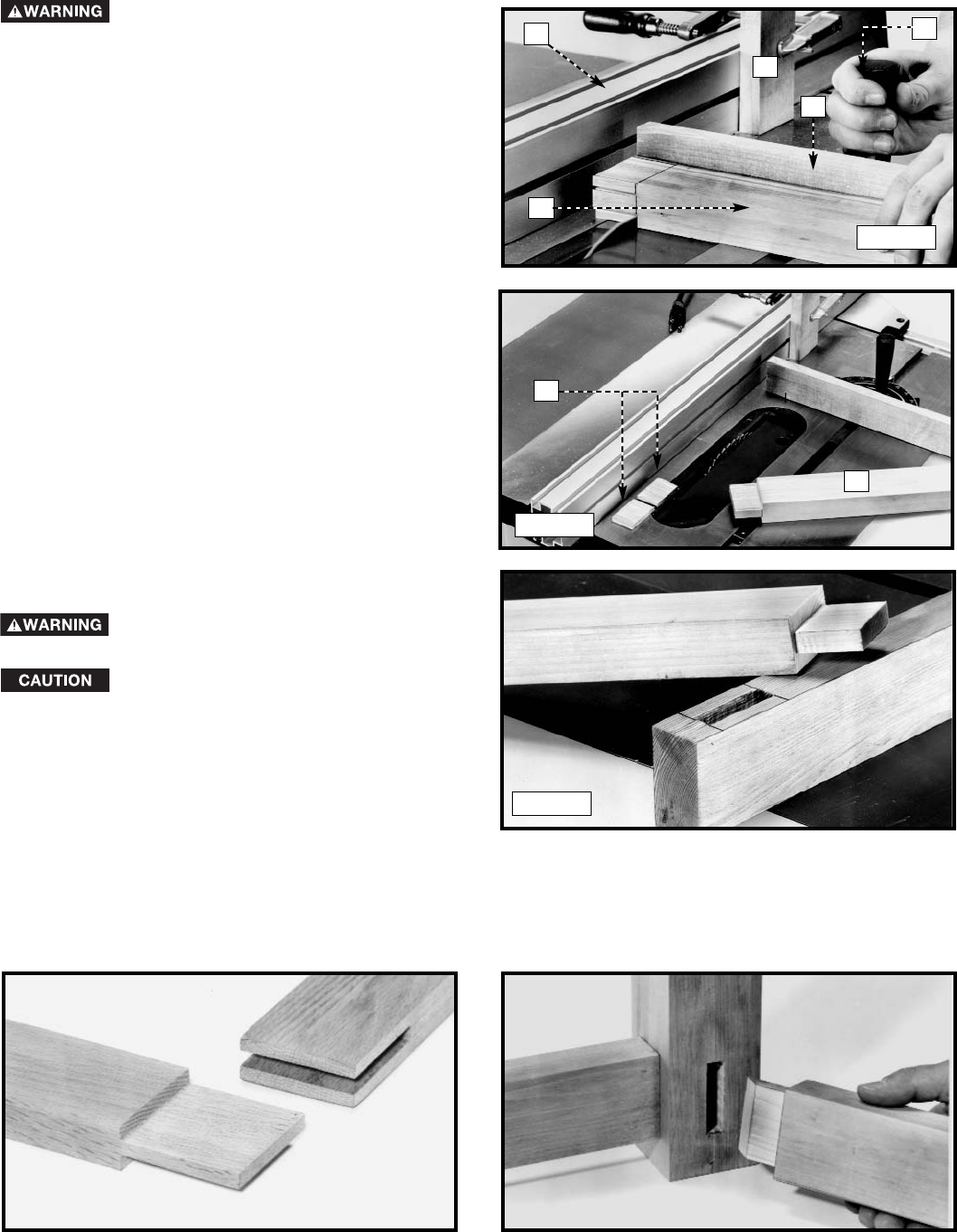

Position the wooden stop block (S)

Fig. 34 in front of the saw blade to

prevent the workpiece from being

trapped between the saw fence and the

saw, causing kickback. Make sure that

the workpiece is clear of the wooden

stop block (S) before contacting the saw

blade.

4. Use a miter gauge (W) Fig. 34, equipped with a backup

board (X), to position the workpiece (L) so that you can

cut the structural shoulders. Make certain that the

workpiece (L) is against the wooden stop block (S) and

the backup board (X).

5. Connect the machine to the power source.

6. Turn the machine “ON” and perform the structural

shoulder cut by slowly pushing the miter gauge (W) Fig.

34 toward the saw blade until the saw blade is

completely through the workpiece. Turn the machine

“OFF”. Wait for the blade to come to a complete

stop and remove the cut-off piece.

7. Return the miter gauge (W) Fig. 34 to the position

shown, and perform the other structural shoulder cut in

the same manner.

8. Fig. 35 illustrates workpiece (L) with the two structural

shoulders (M) cut.

9. Adjust the blade height to perform the cosmetic

shoulder cuts.

10. Connect the saw to power source.

11. Perform the cosmetic shoulder cuts in the same

manner as the structural shoulder cuts.

When performing the shoulder cuts of

the tenon, do not cut into the cheeks of

the tenon. It will greatly reduce the

strength of the joint.

12. Fig. 36 illustrates a simple, or “blind” mortise-and-

tenon joint.

Disconnect Machine from

Power Source

Fig. 34

Fig. 35

Fig. 36

T

S

X

L

W

L

M

OPEN MORTISE AND TENON JOINT MITERED MORTISE AND TENON JOINT